SMT sample small batch processing is an important step between product development and production. This processing process involves preliminary preparation and communication, material preparation and inspection, production processing, quality inspection and packaging, and other processes.

1、 Preliminary preparation and communication

Before starting the small batch processing of SMT samples, both parties need to have detailed discussions to clarify the specific requirements, technical standards, delivery deadlines, etc. of the processing project. This step is crucial as it sets the tone for subsequent work and ensures that both parties have a clear understanding of the project’s expectations and goals.

2、 Material preparation and inspection

According to customer needs, purchase corresponding electronic components, PCB boards, and other materials. The procurement of materials must strictly follow the BOM provided by the customer to ensure the accuracy of the types, specifications, and quantities of materials.

All incoming materials must undergo strict IQC (inspection) before entering the production line. This step aims to screen out materials with unqualified quality, prevent them from entering the production process, and ensure product quality.

3、 Production and processing

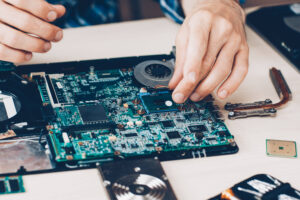

According to the size of the PCB board and the layout of the components, make a suitable steel mesh. Subsequently, use a printing machine to evenly print the solder paste on the solder pads of the PCB board, preparing for subsequent component mounting.

Using an SMT mounting machine, accurately mount electronic components onto designated positions on the PCB board. This step requires extremely high precision, as the position and orientation of the components directly affect the performance and stability of the product.

After installation, the PCB board will be soldered using a reflow soldering machine to form a strong electrical connection between the components and the PCB board. Subsequently, necessary curing treatment is carried out to enhance the mechanical strength and electrical performance of the welding points.

4、 Quality inspection and packaging

Before mass production, a comprehensive quality inspection will be conducted on the first product, including the direction, parameters, and welding quality of the components. This helps to promptly identify and correct potential issues, avoiding large-scale quality accidents in mass production.

After the first piece inspection is passed, it enters the mass production stage. During the production process, AOI (Automatic Optical Inspection) equipment is used to perform real-time testing on each PCB board, ensuring that product quality always meets standards.

After strict quality inspection, qualified products will be properly packaged to prevent damage during transportation. Subsequently, the shipment will be made according to the customer’s requirements to ensure that the product can be delivered to the destination in a timely and safe manner.