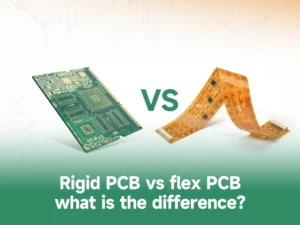

Depending on the material used for fabrication, printed circuit boards can be classified as rigid or flexible. Rigid printed circuit boards include phenolic paper laminates, epoxy paper laminates, polyester glass mat laminates, and epoxy glass cloth laminates. Flexible printed circuit boards are also known as flexible printed circuit boards or FPC. flexible circuit boards are a type of printed circuit board with polyimide or polyester film as the base material, which is highly reliable and flexible. Circuit board. This circuit board has good heat dissipation, can be bent, folded and rolled up, and can be freely moved and retracted in three dimensions. Flexible circuit boards can be used to reduce the size, achieve weight reduction, miniaturization and thinning, thus enabling the integration of component devices and wire connections. Flexible circuit boards are widely used in the computer, communications, aerospace, and home appliance industries.

So what exactly is the difference between a flexible board and a rigid board?

Flexible Circuit Board Product Features:

The small size and light weight of this product greatly reduces the size of the device and lends itself to the development of electronic products towards higher density, smaller, lighter, thinner and more reliable.

It is highly flexible and can be freely bent, rolled, twisted, folded, and wired in three dimensions. It can be arranged arbitrarily according to the requirements of spatial layout, change shape, and move and expand freely in three dimensions for integration of assemblies and wire connections.

Excellent electrical properties, high temperature resistance, flame retardant. Stable chemical change, good stability and high reliability.

It offers high assembly reliability, facilitates circuit design, can greatly reduce assembly effort, and easily ensures circuit performance, reducing the cost of the entire machine. The strength is improved by using reinforced materials to gain additional mechanical stability.

Features of rigid PCBs:

High density. For over a hundred years, the technology for high-density printed circuit boards has matured as integrated circuits have become more integrated and placement technology has advanced.

High reliability. Through a series of inspections, tests, and aging tests, PCBs are guaranteed to work reliably over long periods of time, typically up to 20 years.

Designability. For a wide range of PCB performance requirements (electrical, physical, chemical, mechanical, etc.), printed board design can be standardized and standardized by design standardization in a short and efficient manner.

Productivity. Modern management allows for standardization, scale (volume), automation and other production to ensure consistent product quality.

Testability. Establish more complete test methods, test standards, various test equipment and instruments, etc. to detect and identify the qualification and lifetime of PCB products.

Difference between flexible PCB boards and rigid boards:

Rigid PCBs and flexible PCBs have both similarities and differences.

1. Load capacity of the wires: Compared to rigid PCBs, flexible PCBs have relatively poor thermal performance and therefore must be provided with sufficient wire width. Because the heat dissipation of flexible circuit boards is taken into account, extra width or spacing needs to be given to the wires.

2. Shape. Typically, choosing a rectangle works well to save the substrate and there should be enough available margin near the edges. Sharp inside corners may cause the board to tear. Therefore, smaller wire widths and spacing should be minimized, and transitions must be as smooth as possible. Sharp corners will naturally concentrate stress and cause lead failure.

3. Flexibility: Of course, the flexibility of rigid circuit boards cannot be compared to that of flexible circuit boards. For a lot of bending cycles, flexible boards have better performance.

These are the differences between rigid and flexible circuit boards.