Advanced PCB Manufacturing & Full

Turnkey PCB Assembly

1pcs quick-turn prototypes, fast 2-day fabrication,

and complete full turnkey PCBA — from complex multilayer

boards to production-ready builds.

Best Value

Manufacturer direct pricing

one-on-one assistance

Smooth shopping experience

fast turnaround

As fast as 24 hours

News:

learn more

About Fast Turn

FAST TURN PCB was established in 2015. We own a PCB factory and a PCB assembly factory, employing approximately 350 staff. We focus on providing turnkey solutions for PCB and PCBA, excelling in small and medium-sized volume production and ensuring quick delivery. 70% of our products are sold to Europe and America, 30% are sold to Other market. They are widely utilized in medical devices, industrial control, telecom communication and semiconductors.

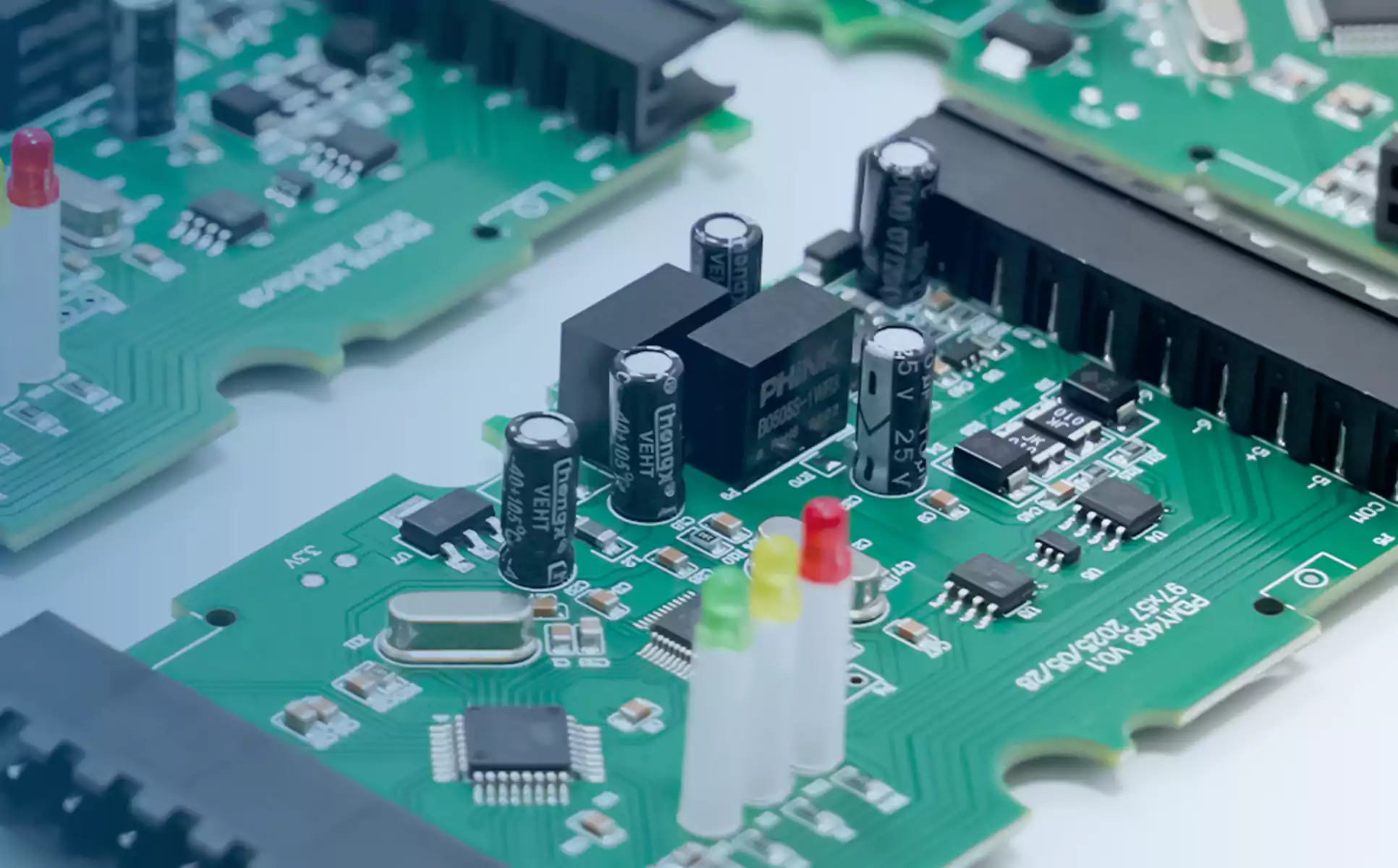

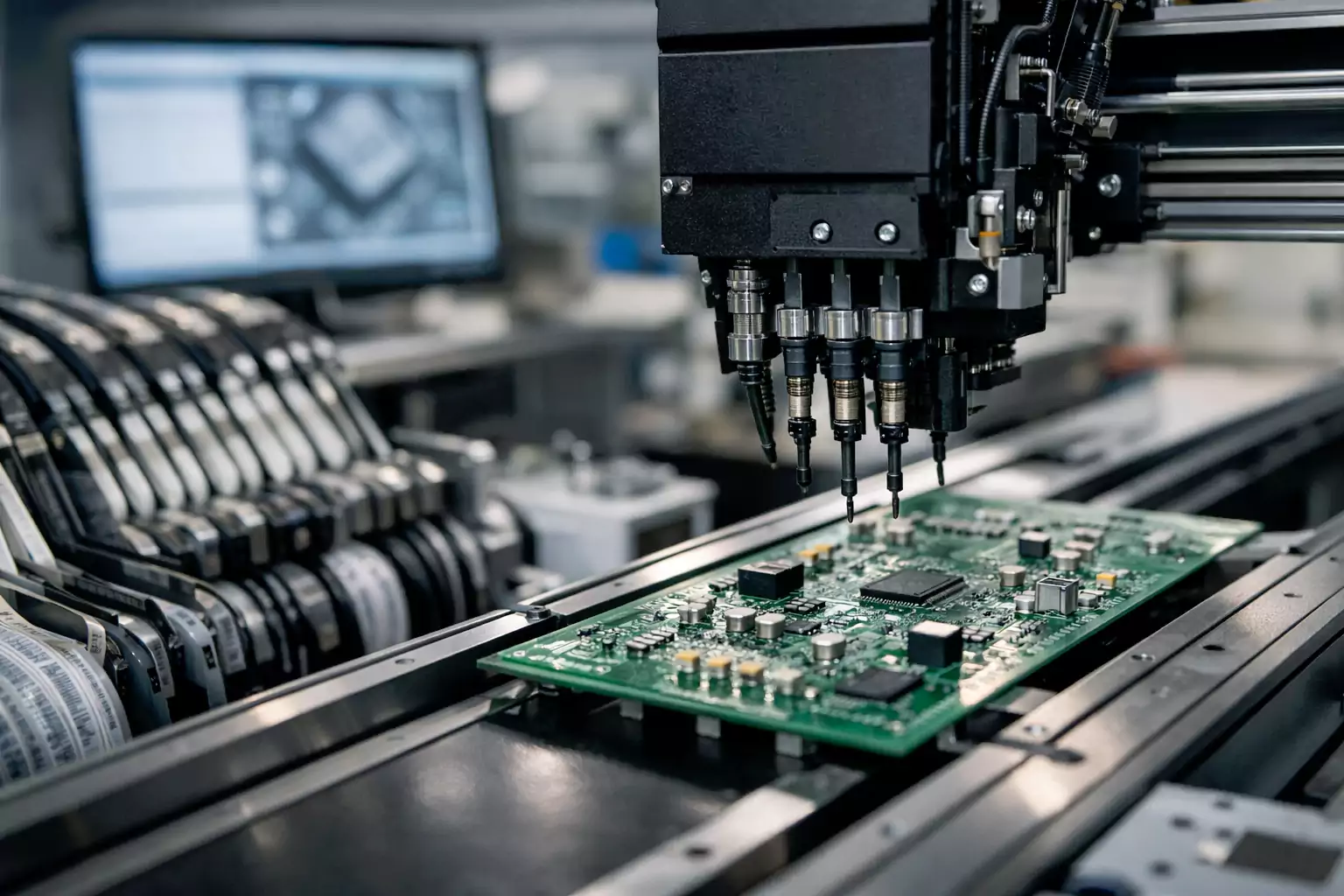

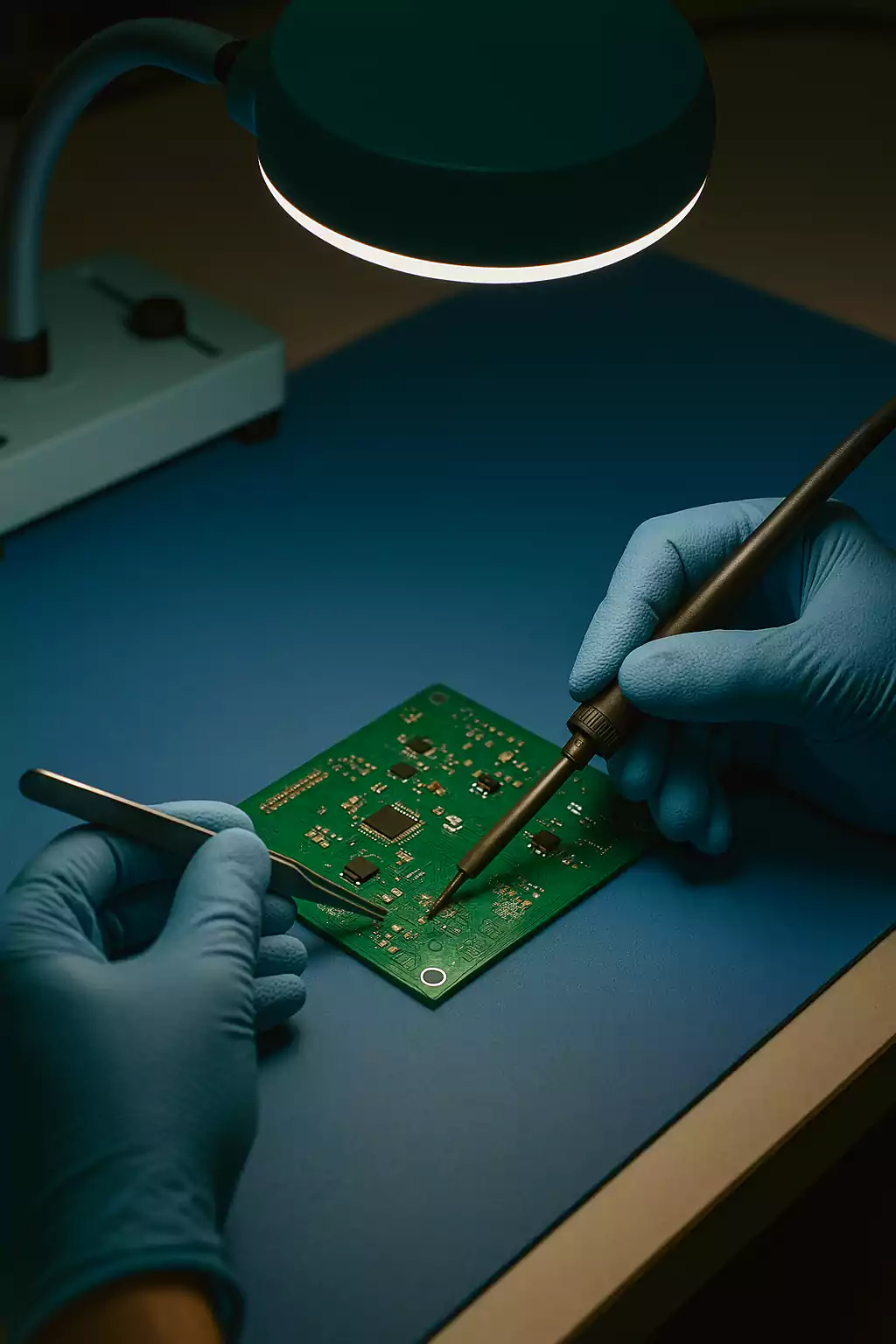

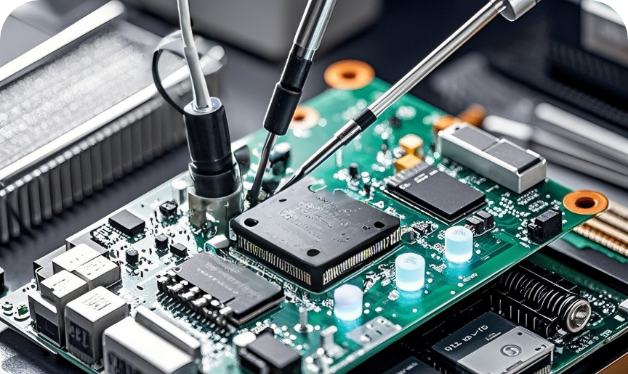

Our PCB factory is Good at multi-layer PCB (4-50 layers), HDI blind and buried boards, high-frequency boards and rigid-flex boards. It is certified by ISO 9001, ISO13485, QJB, UL, ROHS and REACH. Each PCB board undergoes 100% inner and outer layer AOI, E-test, and via hole wall test, and so on.

Our SMT factory has the capacity to handle BGA, QFN, CSP, LGA, 0201, 01005. and some testing .

Our goal is to provide “Reliable Quality, Quick Delivery, Professional Service, and Fair Pricing”.

Reliable PCB turnkey solution provider

FastTurn is one of the world’s most reliable rapid prototyping service providers.

We can transform your designs into physical parts within just a few days

pcb fab

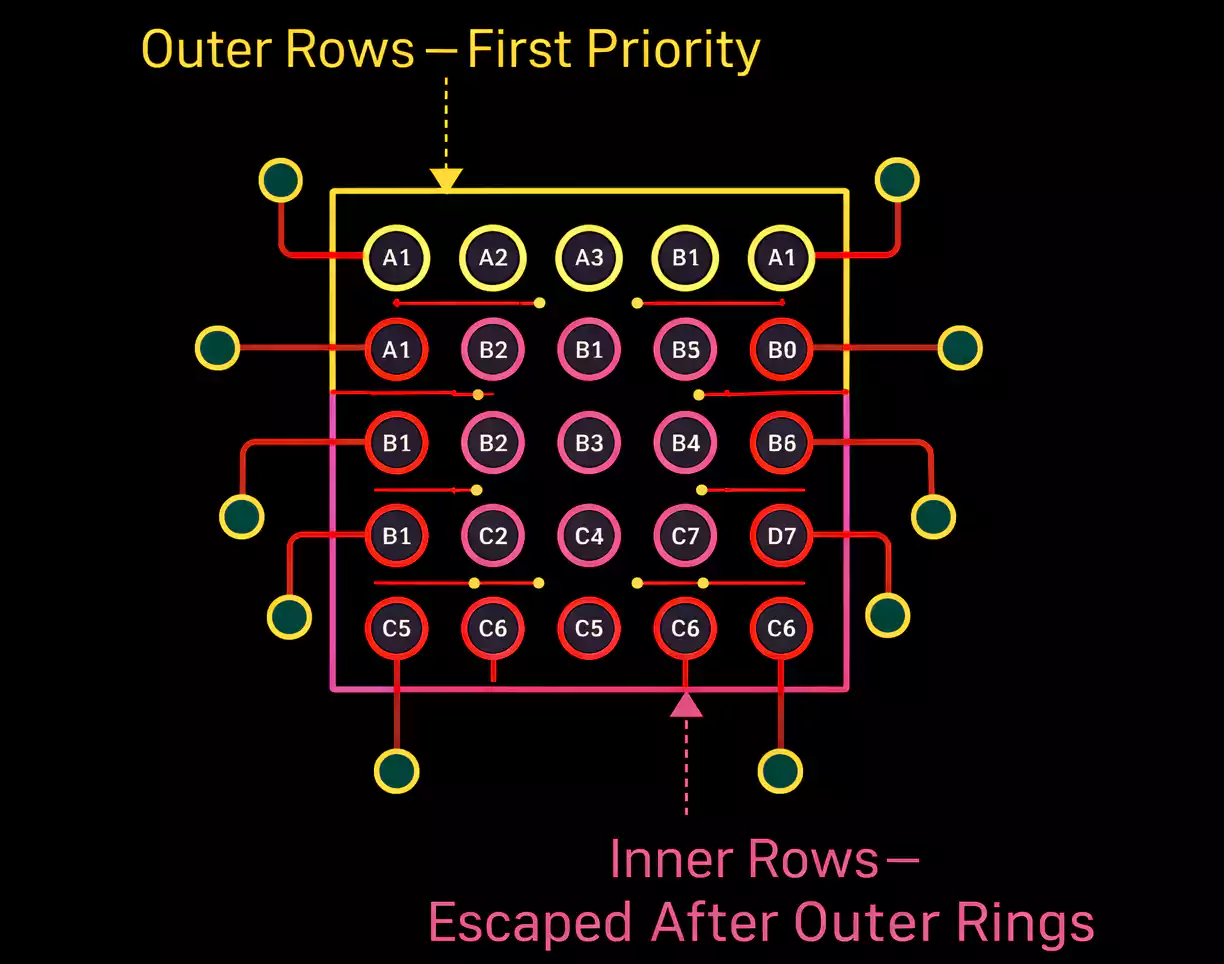

High multi-layer (4-50 layers), HDI,

rigid-flex boards, semiconductor test

boards, etc.

- Get 25% Off Your First Order (Up to $250) !

Turnkey Service

- We are a PCB and PCBA serviceprovider over 15 years.

One-stop service

- Best Value

- one-on-one assistance

- fast turnaround

- Quality Assurance System

- Cost optimization plan

- Flexible production capacity

- Customer value proposition

How to Request a Quote and Start Your Order

Upload your files, get an engineering review, receive a fast quote, and confirm your order — FastTurn ensures a smooth and reliable process from start to finish.

Contact Us Now to Check Your Lead Time

01

Upload files

02

technical review

03

receive quote

04

confirm order

Why choose Fast Turn

Fast Turn PCB focus on providing turnkey solutions for PCB and PCBA, excelling in small and medium-sized volume production and ensuring quick delivery.

Quality Assurance System

Certified with international standards, our end-to-end three-level quality

management system utilizes authorized original materials to ensure product quality compliance with global benchmarks.

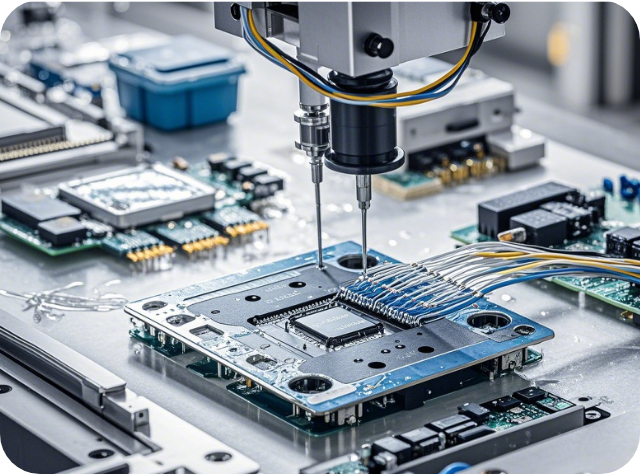

Cost optimization plan

By leveraging bulk raw material procurement and integrated factory operations, we utilize fully automated SMT production lines to achieve cost reduction and efficiency enhancement.

Flexible production capacity

We offer 72-hour rapid prototyping and flexible delivery services, supporting both small-batch trial production and medium-volume orders with full engineering technical support throughout the process.

Customer value proposition

We provide dedicated one-on-one project manager support, 24/7 online technical assistance, and full life-cycle quality traceability.

Quality You Can Trust. Reliable Delivery.

Global Users

Chosen by 9000+ Customers– Your Satisfaction Drives Us Forward.

FastTurn PCB delivers consistent manufacturing quality, fast responses, and dependable delivery for prototypes and mass production. Engineers and OEM teams worldwide rely on us to keep their projects moving smoothly and on schedule.

- US

Great prices, lead times, and quality of work

Great news.Well done,it was fast turn indeed.Your ability to maintain such high standards while delivering ahead of schedule is greatly appreciated. This timely completion has already made a positive impact,Many thanks again for your excellent work.Let's schedule a call next week to discuss the next phase.

DATE OF experience:

July 21,2025

- CA

Completely satisfied with your service and PCBs.

I'm truly delighted with the PCB manufacturing service provided by your company! I checked the PCBs in my design,all specifications meet my requirements perfectly,

I'm completely satisfied with your service and PCBs.

I rate your products and services a perfect 5/5 stars. Thank you for helping bring my electronic designs to life!

DATE OF experience:

May 1, 2024

- UK

Good package with service, price, quality and delivery time.

Tracking number received, Fastturn do a good job!

In the moment I see a good package with service, price, quality and delivery time at

Fastturn, Excels in packaging craftsmanship, service professionalism, cost-effectiveness, product quality, and punctual delivery.Hopefully this will last the next years. Regards.

DATE OF experience:

Apr 07, 2023

- US

Reliable company, outstanding in precision work.

This is tremendous news! Many thanks to you and your team for your dedication and hard work - it's very impressive. I genuinely appreciate your tireless efforts to help us achieve our goals, continuing our productive partnership in future endeavors. Warmest regards and sincere appreciation for making this achievement possible.

DATE OF experience:

Dec 13, 2024

- ISR

We are quire satisfy with your services,thanks.

We received your PCB shipped from Fastturn.We are satisfied with your services. There are no issues with delivery time, circuit board appearance, or packaging.Our team are doing some extra test before making conclusion.Anyway, thank so much for your effort to support us,looking forward to next collaboration. Best regards.

DATE OF experience:

Mar 02, 2024

- SG

We will recommend your company definitely to others.

A pleasant collaboration can be given a score of five

communication: 5 out of 5. Very good communication skills,

leading time: 5 out of 5. The manufacturing time of the PCBs

quality: 5 out of 5. PCB and PCBA quality meets our requirements.

Overall process: 5 out of 5.We will recommend your company definitely to others.

DATE OF experience:

Nov 09, 2024

- US

Well produced,Quick turn,well packaged,fast shipping.

The products are great, really well-made! The whole buying process was smooth and professional, especially how quickly they handled the order. From start to finish, everything worked perfectly—they even packed everything super carefully. You can tell the seller really cares about the details!"

DATE OF experience:

Jul 26, 2024

- US

Received your parts today,they look very good.

Thank you for the expedited shipment - received prototype parts today in perfect condition. Initial inspection appears satisfactory, Your team's remark able speed in both production execution and competitive pricing for this trial order has been impressive. Looking forward to volume production discussions pending test outcomes.

DATE OF experience:

Sept 29, 2024

Your one-stop partner for PCB Manufacturing & Assembly

Turning your PCB concepts into reality takes more than just fabrication. You need a reliable manufacturer who can handle every step of the process — from prototyping to assembly — swiftly, precisely, and with the highest quality standards.

That’s where FastTurn PCB comes in. As a trusted China-based PCB and PCBA manufacturer, we provide end-to-end services including PCB prototyping, multilayer PCB production, component sourcing, SMT assembly, and turnkey PCB assembly. With over two decades of expertise, we deliver products that meet strict IPC, UL, and ISO standards, helping global customers in automotive, medical, telecom, and industrial electronics achieve faster time-to-market and cost-effective manufacturing without compromising quality.

Explore FAST TURN Factory

01

Photos

02

Videos

03

Featured Cases

Insight And Explored

Fast Turn PCB will participate in Iran Elecomp 2025, held this September in Tehran, Iran. As a key electronics trade fair in the Middle East, Iran Elecomp gathers industry professionals across the entire electronics value chain — from components to production and system integration. At the event, Fast Turn PCB will showcase featured PCB samples […]