PCB design is based on the circuit schematic using Allegro, PADS, Mentor, AD and other EDA tools to plan the layout wiring to complete the function of the hardware circuit. Excellent PCB design engineers not only need to understand EDA software, but also circuit principles, SI\PI\EMC, consider the processing capability of PCB board factory, SMT processing manufacturability and other DFM issues. Quality PCB design service is to assist customers to reduce the time and cost of prototyping and lay a solid foundation for them to win the market first!

China’s labor resources, market, investment and other aspects of preferential policies, the absorption of European and American manufacturing transmission, a large number of electronic products and manufacturers to set up factories in China. China PCB output value of the global share of the increasing, the current PCB output value of China’s share of the world is about 60%.

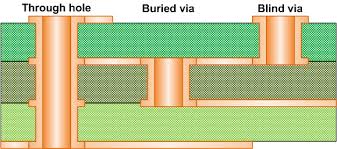

In recent years, as computers, smart phones, electric cars, the Internet of Things and other major terminal applications are becoming more and more widespread, the circuitry is becoming more and more dense, and chip integration is increasing. Many peripheral circuits of the hardware are able to do the work inside the chip. Gradually, hardware design is no longer as complex as it used to be. On the contrary, PCB design becomes increasingly difficult due to the increasing integration of the chip. Multi-layer board, high-speed high-density board, HDI, PCB high-frequency board, PCB blind buried hole board and other design difficulties continue to increase. pcb industry as the central carrier of electronic products, the market demand for PCB design is increasingly strong.

PCB design industry is currently facing the following dilemmas.

First, the serious lack of excellent PCB design talent. As China’s electronics industry is mainly distributed in these first-tier cities in the north, the four cities account for more than 90% of the country’s PCB industry, industrial concentration effect is too obvious, resulting in a serious shortage of PCB designers in second- and third-tier cities.

Second, the high cost of training PCB design engineers in enterprises, long cycle. In addition to some very good large companies such as: Huawei, ZTE, etc. in the early days of internal orientation to foster a number of excellent PCB design engineers, the market is still very short of excellent PCB design engineers. In this context, PCB design outsourcing companies came into being, but despite this, there are still not many excellent PCB design outsourcing companies in the country.

Although the domestic PCB design industry is facing many difficulties and challenges, but the huge market still allows many companies to continue to invest in the PCB industry. Considering the professionalism and high efficiency of PCB design companies, many domestic electronic industrial product companies and circuit board manufacturing companies choose to outsource all or partial outsourcing of PCB design, so that professionals engaged in professional work. According to statistics, Guangzhou Jujin Technology Co., Ltd. has completed more than 1,000 PCB design orders in 2019. Compared with the same period last year, the business volume has more than doubled.

PCB as the “mother of electronics”, is an indispensable part of the electronics industry chain. According to the information response of most customers, different companies have different considerations when choosing PCB design outsourcing needs.

Domestic PCB design outsourcing analysis of several reasons.

- Insufficient in-house PCB design engineers. Some companies have a full-time PCB design team, only when the company’s design team can not meet the needs of the design schedule and design quality, PCB design outsourcing service providers will be looking for.

- Can not catch up with the delivery cycle. Many companies in the market are still allowing hardware engineers to PCB design, hardware engineers also have to do the hardware plan / chip selection / single board debugging and other work, which will inevitably make the time to market is greatly extended.

- With the development of 5G technology, the higher the requirements for high-speed PCB design: signal integrity simulation analysis, timing analysis, signal reflow, crosstalk disposal, single-board EMC/EMI, power ground plane integrity, etc.. Moreover, the design density of the single board is also increasing. These PCB design workload is relatively large, if all by the hardware engineer is responsible for, it greatly extended the product development and time to market.

- It is also difficult to find senior PCB design engineers in the market. From ordinary engineers to cultivate senior PCB design talent, at least 2-3 years of time, and in the process of training, it is difficult to avoid the loss of talent, into the embarrassing situation for others to do the wedding.

Paragraph

- For cost considerations, most small and medium-sized enterprises, they do not have or as long as a few full-time PCB design engineers. The company does not have many projects, recruiting 1-2 full-time PCB planning engineers is a waste of resources. In this case, it is more cost-effective and efficient to choose PCB design outsourcing services. Of course, it is recommended that before choosing a PCB design outsourcing company, it is necessary to understand the strength and background of the outsourcing company in order to prevent unnecessary losses.