Let’s take a look at the concept of flatness and quality control issues of PCB circuit boards together. The flatness of PCB printed boards is determined by two characteristics of the product: curvature and distortion.

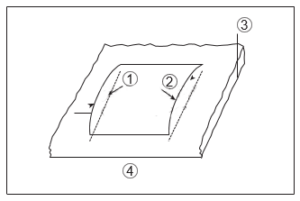

The bending condition of the bow is determined by placing the four corners of the printed circuit board on the same plane, roughly forming a cylindrical or spherical curve (see Figure 1).

Acceptable conditions – Level 3,2,1

For PCB printed boards using surface mount components, both bow and twist should be less than or equal to 0.75%.

For all other printed boards, bow and twist should be less than or equal to 1.50%.

Not meeting the conditions – level 3,2,1

Defects that do not meet or exceed the above requirements.

Note 1 and Note 2: Deviation from surface.

Note 3: Bow bend

Note 4: Apply a coercive force to two corners on the same side.

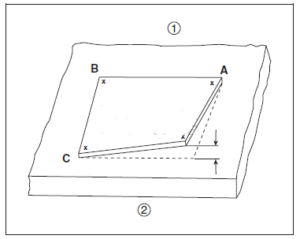

Twisting is the deformation of a plate parallel to its diagonal, with one corner of the plate not in the same plane as the other three corners (see Figure 2). Circular or elliptical printed boards must be evaluated for vertical displacement at the highest point. Bowing and twisting may be influenced by PCB design, as different wiring or multi-layer PCB structures may result in different stresses or stress relief conditions. The thickness and material properties of printed boards are other factors that affect the flatness of printed boards.

Note 1: A, B, and C contact the substrate at three points

Note 2: Apply force to only one corner

Bowing, twisting, or their combination should be measured and percentages calculated using physical measurement methods, in accordance with IPC-TM-650 Test Method 2.4.22, Coordinate Measuring Machine (CMM) or equivalent methods. The finished board should be evaluated according to its received form. The bending and twisting requirements for products assembled for assembly should be determined through consultation between the PCB manufacturer and the customer.