Printed Circuit Boards, also known as PCB, are the underpinning of electrical engineering. It can be associated to the “brains” of any electrical device. In most cases, PCBs are linked with computers. However, they are also common to several powered devices like cameras, radios, televisions, cellphones, and many more. Since PCB is a foundation for supporting and wiring small components and surface-mounted electronics, it is crucial to every electric company.

The process of assembling or soldering any electronic components to a PCB is called Printed Circuit Board Assembly or PCBA. Now, the assembly of a circuit board is different from the PCB production process. Manufacturing PCBs involves multiple steps, including creating a PCB prototype and PCB designing. Once a PCB is ready, passive and active electronic components need to be fused onto it before it can be utilized in several gadgets or electronic devices. This assembly of electronic parts depends on the type of PCB, the purpose of the circuit board, and the type of electronic parts.

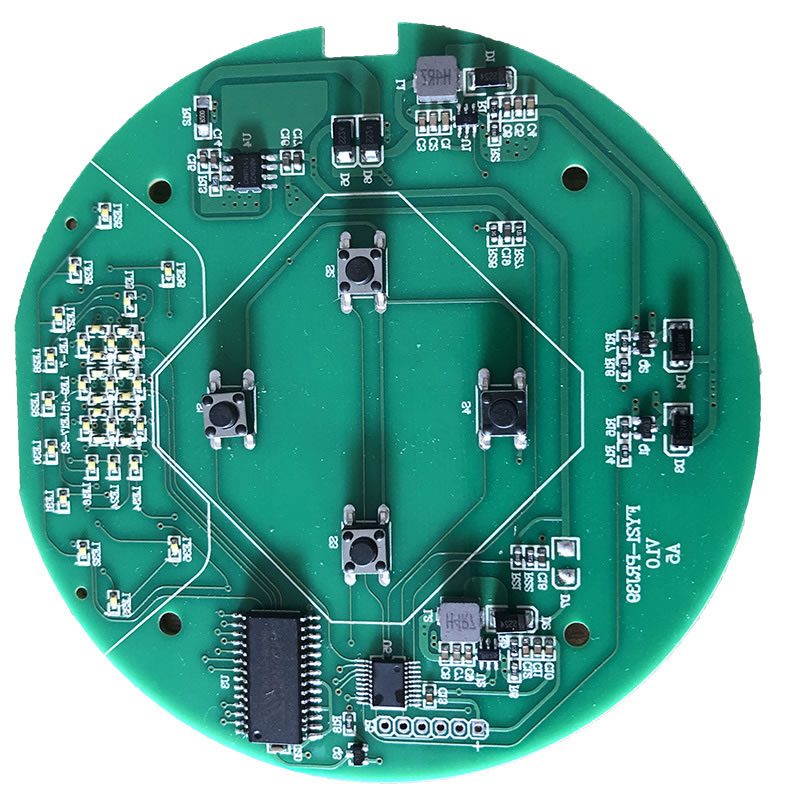

Each PCBA board has an exceptional function for a certain product. It must be designed to do that function in the allotted space. PCBA board designers often utilize computer-aided design systems with unique software to outline the circuit pattern on the board.

The best and easiest solution for purchasing PCBs online is through a professional service. Thanks to Fast Turn PCB, everything is perfect. You can order printed circuits that suit your company’s needs and receive your order right at your doorstep.

PCBA Board at Fast Turn PCB means top technology, strict quality testing, innovative PCB assembly and inspection devices, and structured manufacturing schemes. With us, you are certain that you will get the highest quality solutions at an affordable cost.

Buying PCBA Board from Us

Fast Turn PCB specializes in reliable and high precision printed circuit manufacturing for more than 14 years. Our experience in the field gives us an idea of how to meet the needs of our customers fully. Our services offer the chance to set up and purchase online printed circuits instantly.

To meet the needs of our clients, we always follow a certain procedure to keep the details of every design. To create a perfect PCBA board, here are the steps we follow:

• Setup — We never fail to impress our clientele through considering basic things like materials required, procedure, customer specification, and clients’ satisfaction.

• Etching or Patterning — Our team removes the unsecured copper by the etch-resist film. This leaves the secured copper wads and touches in place.

• Engraving photos — A photo mask is mixed with chemical etching. The main purpose of this is to reduce the copper areas from the PCB boards.

• Multilayer Pressing — This is one of the significant steps in PCB manufacturing as it involves the alignment of conductive copper and the insulation of di-electric layers. We do this to form a solid board material.

• Drilling — This process involves the drilling of holes. The detail is stuck in a place where the hole is made up to be pierced.

• Masking — In this process, a secured sheet is applied over the copper.

• Finishing — Our team coated the pad areas with a thin solder layer to prepare the PCBA board for wave soldering.

• Electrical Testing — This is the last touch. Our team diligently checks the shorted or continuity PCB manufacturing connections. We do this by applying a voltage between the points.

Searching for the best company that offers one-stop services may be a tricky task. This is common, especially when you have no idea about the different companies around you. Instead of worrying about where to depend on, why not try Fast Turn PCB?

Our company is a one-stop service integrating PCB board making, PCB design, mass production, and PCBA sample express. With our commitment to providing the best products and services to our customers, our company becomes one of the choices in various places.

With us, you don’t have to worry about your limited budget. We can offer you a perfect deal while getting the best product and services you opt to have.

Still, searching for the best PCBA board? Then, feel free to contact our team. Just like others, you will surely be hooked on what we can offer for your business!