Electronics are running the world, and it has become an indispensable part of human lives. From the tiniest gadget to the gargantuan technological machine, it is all being operated by electronics. The very core of these electronics is the printed circuit board assembly or commonly called PCB.

If you inspect your mobile gadgets like your smartphones, you may see the green chips covered in lines and copper parts. Basically, a PCB is being made from the materials like fiberglass, copper lines, and other metals, which are being put together through the use of epoxy and insulated with the solder mask. The green color of the PCB can be attributed to the solder mask.

It is called an assembled PCB once the components are mounted on the PCB. The PCB assembly or PCBA is what is being referred to in the manufacturing process.

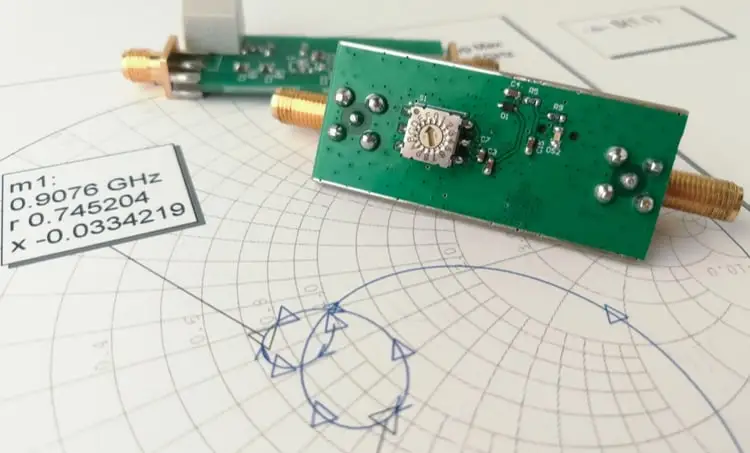

Traces is the copper lines in the bare board, and it electrically joins the components and connectors. The printed circuit board assembly functions specifically according to its design through the signals being transmitted by the different components.

To give a clearer picture of the PCB assembly process, we will have a PCBA 101 to understand the detailed process. There are two options for the board manufacturer to choose from, which are the manual and the automated. Let us walk through the different stages in the PCB assembly process;

Basic Designs of Printed Circuit Board Assembly

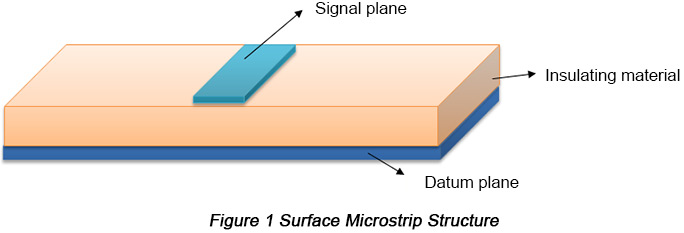

The base is the basic unit of the PCB, and it is where the PCB assembly starts. The base has several alternating layers such as the substrate, copper, solder mask, and silkscreen. Let us take a look at each one in detail.

The base material of the PCB and give its rigidity is the substrate. The copper is the thin layer that is being attached to the functional side of the PCB. If it is single-sided the thin copper foil is just being added to one side, and if it will be added on both sides if it is a double-sided PCB. The green color of the PCB is due to the Solder mask that gives its distinct color. The solder mask is on the top of the copper layer, and it insulates copper traces from any accidental contacting other conductive materials. The solder mask’s holes are where the solder is being applied to attach the components to the board. Since the solder mask is the one that holds everything in place, it becomes a crucial part of the smooth manufacturing of PCBA. The final layer in the PCB board is the white silkscreen. It is in this layer that characters and symbols are being added to the PCB for to indicate the functionality of each component on the board.

Across all Printed Circuit Board Assembly, you can see all those materials and components with one exception, which is the substrate, for it may vary according to specific qualities such as cost and bendability.

You can count on Fast Turn PCB in the Printed Circuit Board Assembly industry, which already earned its mark as a leading high-tech Printed PCB Circuit Assembly manufacturer. It is has been in the PCB industry for almost 12 years. The very core of this company is “quality” service and products to the clientele. It has a varied specialization ranging from prototyping PCB down to manufacturing and PCB assembly. You can be assured that the PCB is a product of the intensified effort of the Research and Development team of the company.