When it comes to new hardware products, the smaller the product, the better, especially for wearable technology products and IoT products.

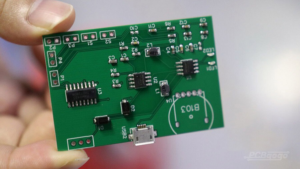

One of the keys to smaller hardware products is, of course, smaller printed circuit boards (PCBs).

If small size is critical to your product, then the technique to reduce the size of the PCB is to use blind and buried vias. Their use allows for tighter packaging of components on the PCB.

Through-holes are the pathways that connect the alignments between the various board layers. Standard vias through each layer of the board actually reduce the available wiring space, even on layers that are not connected to these vias. Less available wiring space means a larger board size.

This is where the so-called buried and blind holes come in to help eliminate this problem. The blind hole connects the outer layer to the inner layer, while the buried hole connects the two inner layers.

However, designers need to consider the use of blind and buried holes.

The first issue with blind and buried holes is cost. The process of making blind and buried holes is more complex than conventional through-holes, and therefore can add significantly to the cost of the board.

For high volume production, the cost of blind buried vias will be reduced to a more manageable level, but for small quantities of HDI circuit board prototyping, the cost increase can be significant. Many times, using blind and/or buried holes can triple the cost of a PCB prototype!

The second problem with using them is that they have strict limitations on the layers that can be used to connect them. To understand their limitations, you must understand how to stack the layers to make the board.

Let’s start by looking at a 4-layer PCB with four stacked layers, as shown below.

In the image above, through-hole #1 is a classic through-hole, through-hole #2 is a blind hole, and through-hole #3 is a buried hole.

When using this layer stack, blind holes can only be used to connect L1 to L2, or L3 to L4.

Buried holes, on the other hand, can only be used to connect L2 to L3.

You cannot use blind holes to connect L1 to L3 or L2 to L4. This is because the start and end of each through-hole must be located at the distal end of the core to maintain structural integrity during drilling.

It gets more complicated because instead of selecting a stack of copper, core, copper, prepreg, copper, core, copper as shown above, you select the stack as copper, prepreg, copper, core, copper, prepreg, copper.

With this layer, blind holes can now be created to connect L1 to L3, or L2 to L4, but not L1 to L2 or L3 to L4.

Confused? Like I said, the use of blind/buried holes can get very complicated.