I. The calculation is as follows

First calculate the cross-sectional area of Track, most PCBs have a copper foil thickness of 35um (ask the PCB manufacturer if you’re not sure, 1 oz is 35um, in fact, they’re all less than 35um) it multiplied by the line width is the cross-sectional area, note the conversion to square millimeters.

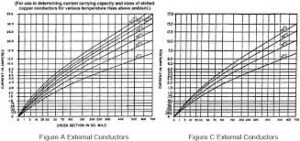

There is an empirical value for current density of 15 to 25 Amps/mm2. I=KT0.44A0.75 (K is the correction factor, typically 0.024 for copper-clad wire in the inner layer and 0.048 for copper-clad wire in the outer layerT is the maximum temperature rise in degrees Celsius (the melting point of copper is 1060°C) A is the cross-sectional area of copper-clad wire in square MIL (not mm mm, note the square mil.)I is the maximum allowable current in amperes (amp) Generally 10mil=0.010inch=0.254 can be 1A, 250MIL=6.35mm, 8.3A

II. Data

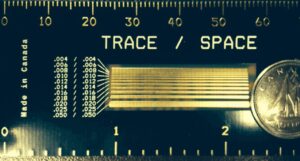

The calculation of PCB current-carrying capacity has been lacking authoritative technical methods and formulas, and experienced CAD engineers can make more accurate judgments based on personal experience. The current-carrying capacity of a PCB depends on the following factors: line width, line thickness (copper foil thickness), and allowable temperature rise. We all know that the wider the PCB alignment, the greater the current-carrying capacity. Here, please tell me: assume that under the same conditions, 10MIL alignment can withstand 1A, then 50MIL alignment can withstand how much current, is 5A? Naturally, the answer is no. See the following data from international authorities: the unit of line width is: Inch (inch inch = 25.4 millimetres mm) 1 oz. copper = 35 micron thick, 2 oz. = 70 micron thick, 1 OZ = 0.035mm 1mil. = 10-3inch. Trace Carrying Capacity per mil std 275

Three, experiments

The experiment also has to take into account the voltage drop caused by the wire resistance due to the length of the wire. The tin on the process solder is just to increase the current capacity, but it is difficult to control the volume of tin. 1 OZ copper, 1mm wide, is generally used as a 1 – 3 A current meter, depending on your wire length, and the voltage drop requirement.

The maximum current value should be the maximum allowed under the temperature rise limit, the fusing value is the one where the temperature rise reaches the melting point of copper. eg. 50mil 1oz temperature rise 1060 degrees (i.e. copper melting point), the current is 22.8A.

IV. PCB design copper platinum thickness, line width and current relationship

Before understanding the PCB design copper-platinum thickness, line width and current relationship let’s understand the conversion between PCB copper thickness in ounces, inches and millimeters: “In many data sheets, PCB copper thickness is often measured in ounces, which is converted to inches and millimeters as follows:

1 ounce = 0.0014 inch = 0.0356 millimeter (mm)

2 ounces = 0.0028 inches = 0.0712 millimeters (mm)

Ounces are units of weight and can be converted to millimeters because the copper thickness of the pcb is ounces per square inch” PCB design copper platinum thickness, line width and current relationship table

The current carrying value of the wire is directly related to the number of pads in the wire line perforation (currently there is no formula to calculate the impact of pads and perforation aperture per square millimeter on the carrying value of the line, friends who are interested can find out for themselves, I’m not too sure, not in the description) Here is just a brief look at some of the main factors that affect the current carrying value of the line.

1. The values listed in the table are the maximum current carrying capacity at room temperature of 25 degrees Celsius, so in actual design, various environmental, manufacturing process, panel process, panel quality and other factors must be considered. Therefore, the table is provided as a reference value.

2, in the actual design, each wire will also be affected by the pad and over-hole, such as the pad taught more line segments, after the tin, the pad that section of its current carrying value will greatly increase, many people may have seen some high current board between the pad and the pad a section of the line was burned, the reason is very simple, the pad because after the tin because there are components and solder to enhance the current of its section of the wire Carrying value, and the pads and pads between the pads it is the maximum current carrying value of the width of the wire allows the maximum current carrying value. Therefore, in the instantaneous fluctuations in the circuit, it is easy to burn the pad and pad between that section of the line, the solution: increase the width of the wire, such as the board does not allow the increase in the width of the wire, in the wire to add a layer of Solder layer (generally 1 mm of the wire can add a Solder layer of about 0.6 wire, of course, you also add a 1mm Solder layer of wire layer of wire) so that after tinning, this 1mm wire can be seen as a 1.5mm~2mm wire (depending on the uniformity of the tin and the amount of tin when the wire is tinned), as follows:

This type of processing is not new to those who work with small appliance PCB Layout, so if the tinning is uniform and the amount of tin is sufficient, the 1mm wire can be seen as more than a 2mm wire. This is important in single-sided high-current boards.

3. The same method of processing around the pads in the diagram is to increase the uniformity of the current carrying capacity of the wires and pads, this is especially important in boards with high current thick pins (pins larger than 1.2 or more, pads above 3) so processing is very important. Because if the pad in the 3mm above the pin and more than 1.2, it is in the tin, this point of the pad current will increase by dozens of times, if the large current instantaneous great fluctuations, this whole line current carrying capacity will be very uneven (especially when the pad more), it is still easy to cause the pad and pad between the possibility of line burn off. The graphical treatment can effectively disperse the uniformity of the current carrying capacity of individual pads and surrounding lines.

Last but not least, the current carrying value data sheet is only an absolute reference value. When not designing for high currents, a 10% increase in the data provided in the table will definitely satisfy the design requirements. In general, single panel design, with a copper thickness of 35um, can be designed at a ratio of 1 to 1, which means that a 1A current can be designed with 1mm of wire and meet the requirements (at a temperature of 105 degrees).

V. PCB design, copper foil thickness, alignment width and the relationship between the current

The current strength of the signal. When the average current of the signal is larger, the wiring width should be considered to carry the current, the line width can be referred to the following data.

The relationship between copper foil thickness, line width and current in PCB design

Different thicknesses, different widths of copper foil current-carrying capacity is shown in the following table:

The alt attribute of this image is empty; the file name is Figure 4-1.jpg

Paragraph

Notes.

When using copper skin as a wire through the high current, the copper foil width of the current-carrying capacity should refer to the table of the value of 50% derating to choose to consider.

In PCB design processing, commonly used OZ (ounce) as the unit of copper skin thickness, 1 OZ copper thickness is defined as the weight of copper foil in an area of 1 square foot for an ounce, corresponding to the physical thickness of 35um; 2OZ copper thickness of 70um.

VI Empirical formula

I=KT0.44A0.75

(K is the correction factor, generally copper clad wire in the inner layer to take 0.024, in the outer layer to take 0.048T is the maximum temperature rise in degrees Celsius (copper melting point is 1060 ℃)

A is the cross-sectional area of the copper cladding in square MIL (not mm mm, note that it is square mil.)

I is the maximum allowable current in amperes (amp)

General 10mil = 0.010inch = 0.254 can be 1A, 250MIL = 6.35mm, for 8.3A

Seven, a little experience on the line width and over-hole copper laying

We generally have a common sense when drawing PCB, that is, take the place of high current with thick lines (such as 50mil, or even above), small current signals can be used with thin lines (such as 10mil). For some electromechanical control systems, sometimes the instantaneous current flowing through the line can reach 100A or more, so that the thinner line will certainly be a problem.

A basic empirical value is: 10A / square mm, that is, the cross-sectional area of 1 square millimeter of the cable can safely pass the current value of 10A. If the line width is too thin, in the high current through the cable will be burned. Of course, the current burn line also has to follow the energy formula: Q = I * I * t, for example, for a 10A current line, suddenly a 100A current burr, the duration of us level, then the 30mil wire is certainly able to withstand. (Another problem arises at this point? The stray inductance of the wire, the burr will produce a strong reverse electric potential under the action of this inductance, which may damage other devices. (The thinner and longer the stray inductance of the wire, so in practice, the length of the integrated wire to consider)

General PCB drawing software for the device pins over the hole pads often have several options when laying copper: right-angle spokes, 45 degree angle spokes, straight lay. What is the difference between them? Novice often do not care too much, just choose one, beautiful on the line. In fact, it is not. There are two main considerations: one is to consider not too fast heat dissipation, the second is to consider the ability to over-current.

The use of straight pavement is characterized by the pad’s over-current capability is very strong, for high-power circuit device pins must be used in this way. At the same time it is also very strong thermal conductivity, although the work of the device heat dissipation is good, but this is a problem for board welders, because the pad heat dissipation is too fast not easy to hang tin, often need to use a larger wattage of the soldering iron and higher welding temperature, reducing production efficiency. The use of right-angle spokes and 45-angle spokes will reduce the contact area between the pins and copper foil, slow heat dissipation, and much easier to solder. So the choice of copper pads through the hole paved connection according to the application, a comprehensive over-current capacity and heat dissipation capacity together, small power signal lines do not use straight paved, and for the pads through the high current must be straight paved. As for the right angle or 45 degree angle depends on the aesthetics.

Why bring up this to it? Because a while ago has been studying a motor driver, the driver in the H-bridge device always burned, four or five years can not find the reason. After some hard work finally found: the original is a device in the power circuit pads in the laying of copper when the use of right-angle spokes of the laying of copper (and because of the poor drawing of the laying of copper, the actual appearance of only two spokes). This makes the whole power circuit overcurrent capacity is greatly reduced. Although the product does not have any problems during normal use and works perfectly fine at 10A current. However, when there is a short circuit in the H-bridge, a current of about 100A occurs in this circuit and the two spokes instantly burn out (uS level). Then, the power circuit becomes broken, and the energy stored in the motor is dissipated by all possible means without a lagging channel. This energy will burn up the current measuring resistor and related op-amp devices, destroy the bridge control chip, and flee into the digital circuit part of the signal and power supply, causing serious damage to the whole device. The whole process is as thrilling as using a hair to detonate a large mine.