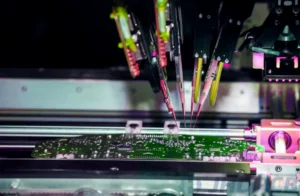

With the rapid development of the PCB industry, test equipment is constantly being updated technologically, and the market demands more and more stability and efficiency from test equipment. In order to make the test equipment as stable as possible, people have a pivotal role in ensuring that the test equipment is stable, reliable and efficient. In the testing process, the phenomenon of false open circuit will inevitably occur, especially when the false open circuit more (≥ 10) situation, the operation and process personnel should draw attention to the equipment, process data and printed circuit board products should be analyzed and solved. I am in the equipment maintenance and related equipment process feedback analysis of the actual work, this paper to the Italian Seica series PCB flying probe test as an example, the PCB flying probe test equipment false open circuit more analysis of the causes of the phenomenon and the solution strategy for the corresponding summary for the peers to refer and discuss.

I. Determine whether it is caused by the instability of the device The easiest way to determine whether the device is working properly: use the original test qualified old file data and the corresponding qualified PCB board (remove the surface of the oxide, etc.) for testing, if there is still an open circuit then it should belong to the device failure, and vice versa it should belong to the process data or the printed circuit board to be tested problem, when When the equipment is out of question, use the following methods to check and analyze.

1. Software overhaul

First, use the device’s overhaul (also called self-test) software to run according to the prompts to see if any damaged parts or errors are found: if there are damaged parts or errors, then the corresponding parts should be replaced and corrected according to the error prompts.

Second, use the DMC software to check whether the feedback system of each axis is working properly, and its correct operation steps are: test system minimization → under the (Start\Program\\DMC) program or open the DMC on the desktop (DMC TEST interface appears) → press the emergency stop switch → move each axis by hand, observe the grating feedback system of each axis digital changes and sensitivity DMC and TESTZ.DMC→RUN to observe whether each axis can return to zero position (each corresponding axis position reading is ‘0’).

2, hardware failure Hardware failure in all failures is more likely to occur, because the test system is good or bad and test equipment working environment (temperature, humidity, etc.), the length of working time, maintenance and other factors are closely related, according to my summary, hardware failure Z-axis linear motor, scale, scale feedback data line adapter The hardware failures are Z-axis linear motor, scale, scale feedback data line adapter, and L-type flying probe (Probe).

(1) Z-axis linear motor: Because of the long time and high frequency operation of linear motor, it is easy to make the motor moving parts black and produce black scale, resulting in inflexible up and down, motor load increase and so on. Therefore linear motor should be regularly (about 6 months) removed with anhydrous alcohol for cleaning, removed and cleaning must be careful when the guide ball slipped.

(2) scale: the scale is the core component of all high-precision equipment positioning, the scale is directly related to the accuracy and stability of the equipment. But most of the scale are because of the environment is not good or poor air supply caused by the workshop environment may make the scale surface accumulate too much dust, dust directly affect the feedback signal, thus leading to the phenomenon of more open circuit. In order to clear the dust on the scale should be cleaned with anhydrous ethanol, pay attention to the cleaning should be gently cleaned in a single direction with a fine glove (dipped in a little anhydrous alcohol), can not scrub back and forth and force too much (to prevent scratching the grating); at the same time require the air source to be dried, filtered oil, filtered water into the equipment, otherwise it will affect the service life of the equipment and measurement accuracy.

(3) Lenticular data feedback line adapter: PCB flying probe test equipment moves faster, once the equipment is in working condition the whole machine will have a strong jitter. Therefore, the raster data line connector may generally be due to inertia, after a period of use will be poor contact between the socket, in order to avoid the situation, the plugs should be checked before turning on the machine every day.

(4) L-type probe: the good or bad of the stylus is also one of the important factors causing open circuit, the stylus is mainly manifested by blunted tip, poor contact between the needle and the needle plug and regular needle calibration (at least 1 time / week). When the stylus is blunt must replace the stylus, after changing the needle remember to zero the number of times it is used, always check whether the needle and the needle is loose between the head, to ensure that the stylus is automatically corrected at least once a week.

Second, the process data conversion new file process data in the first generation of errors, which is also the cause of open circuit, many process personnel in the CAM data conversion, the generated network diagram file errors, most cases belong to the layers, face of the hole or pad properties are not consistent. Therefore, once it occurs, the process personnel are required to repeatedly review the data file.

Three, printed circuit board product problems If, in addition to the exclusion of test equipment and process data, another situation should belong to the PCB product itself there are problems, mainly in warpage, solder resist, character irregularities.

(1) Warpage: Some production planners often omit the hot air leveling process in order to hurry up and send it directly to final inspection. If the product is not hot leveled, the warpage is greater than the warpage range allowed by the testing equipment. Therefore, the hot leveling process can not be missing, but also requires the inspection and testing personnel to add warpage measurement before testing.

(2)Solder Resist: Often the more open circuit products are measured because some of the conduction holes are blocked by the solder resist layer and the measured results are unsatisfactory, the test should try to avoid the adapter hole (or ensure that the hole conduction is correct) when testing.

Auto Sync with Cloud

No manual interaction required.

(3) Characters: Many PCB manufacturers print characters before electrical testing, as long as the characters are printed in a slightly offset position or the character negative is not accurate enough, the fine gauge stickers and small holes may be partially covered by the characters. Therefore, in order to avoid open circuit caused by the character, with a fine table stickers, small holes (Φ & lt; 0.5), fine lines of high-density printed circuit board should be first electrical testing after the character process is more reasonable.

The causes of electrical test false open circuit are many, but the general situation is not outside the above three situations, in order to quickly eliminate the problem should be based on the specific circumstances of a specific, comprehensive analysis to improve the effectiveness.