In recent years, China has gradually become the main production base of global printed circuit boards, from 2008 to 2016, the global share of China’s PCB output value is climbing, from 31.18% in 2008 to further increase to 47.36%, the global PCB industry production capacity (especially high multilayer boards, flexible boards, packaging substrates and other high-tech PCB) further to mainland China and other Asian regions to concentrate. Although China has become the world’s largest PCB producer, the number of PCB enterprises, but also the world’s largest capacity to provide PCB and one of the most complete product types of the region, but the scale and technical level of local enterprises vary, for the majority of designers and buyers, it is difficult to assess the quality level of PCB suppliers, good or bad, it is easy to accidentally choose the quality control The quality of the PCB is very high and the quality of the PCB is very low, so it is easy to choose a reliable PCB supplier.

- Note the full weighing of factory positioning and production strength:

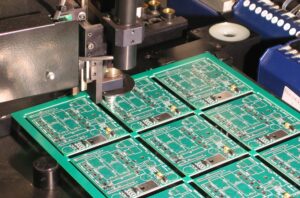

There are many PCB factories in China, and each factory has its own positioning, according to the amount of sub-expedited prototyping, small batch medium batch large batch, according to the production difficulty of simple board, high level board difficulty board, etc., in the selection of factories to first clarify their needs, targeted to find the corresponding expertise of the factory, by understanding the PCB manufacturer’s production scale, the degree of perfection of equipment, etc., a more intuitive judgment of the comprehensive strength of PCB manufacturers. PCB production reputation manufacturers must have a strong production strength as a backing, the strength of the production is directly related to the contract as promised and the quality of PCB. Guangzhou club into technology is the fastest in South China to provide PCB one-stop (design – production – placement) service company, positioning in the high-end PCB fast board and small batch, created by the senior staff engaged in circuit board manufacturing for more than 15 years, with advanced production technology, perfect test equipment, since April 2018, the introduction of a new automatic plating line, high-speed flying probe test machine, drilling machine, strengthen The company has been introducing new automatic plating lines, high-speed flying probe testers, and drilling machines since April 2018 to strengthen its own production strength.

- Evaluating the reputation of PCB suppliers

The reputation of PCB manufacturers can be examined from several aspects such as the company’s business license, domestic and international certifications, customer reviews, quality process monitoring system, etc. We have obtained ISO-9001 and UL-E471959 certifications, and 40% of our PCBs are sold to well-known electronics companies in the US, Japan, and Asia, and we have established good relationships with these well-known companies and research firms.

- Focus on the service of PCB suppliers

The purchase of PCBs involves a variety of issues, such as engineering evaluation recommendations, production process, production quality, production schedule, testing, etc., and requires a comprehensive service system to ensure service quality. We can provide professional laminated impedance design, pre-production and design evaluation for manufacturability, coordination between design parameters and process capability and cost, material recommendation to meet designer’s signal requirements, fast and professional online consultation answer, production process, production quality, production schedule, testing, etc. Each link is controlled and docked by a dedicated engineer.

Fourth, pay attention to the professionalism of the quality control staff

Every PCB manufacturer is equipped with quality assurance personnel for the inspection of finished PCBs, and the finished products will be handed over to customers only after passing the inspection. process should pay attention to understand the quality control standards and processes. All of our circuit boards must undergo the most rigorous inspection, not simply manual visual inspection, and we use the testing and inspection equipment used in the industry, such as flying probe testers, X-ray inspection machines and automatic optical inspection equipment.

V. Be aware of the guaranteed delivery time

PCB lead time is very important for product design, placement, testing, product launch, lead time after lead time is never acceptable for new product development, PCB supplier past order lead time is very important; Our company (Jujin Technology) In those past years, we have maintained on-time delivery rate of 99%. We all know that in addition to product quality, another most important factor is the shortest lead time, which is especially important for engineers to carry out their development research work.

For more information, please visit: www.jujinpcb.com