Main Menu

Advanced PCB

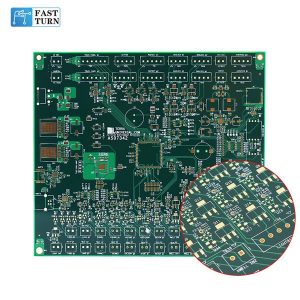

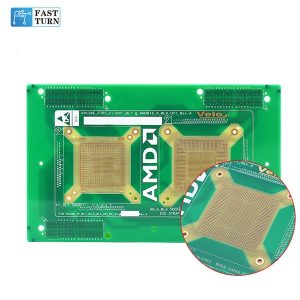

4 Layer Big Area Immersion Gold back drill PCB Circuit Board

| Item: | 4V2HC52A1 | Layer: | 4 |

| Material: | FR4 TG170 | Thickness: | 1.0mm |

| Min. Line width and space: | 4/4mil | Min.Hole size: | 0.3mm |

| Surface finish: | ENIG | Cooper thickness: | 1.0/1.0 OZ |

| Impedance control: | No. | Leading time: | 7 working days |

For quotation, please contact James:+86- 18011866680

Send you gerber file to Email: sales@fastturnpcbs.com

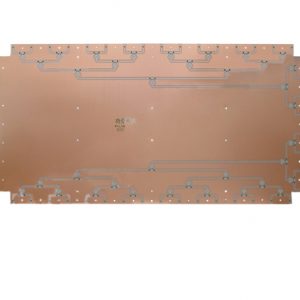

Some of our customers are as follows: