PCB material

Currently, the commonly used double-sided PCB materials are FR-4 and CEM-3 substrates. Both materials are flame retardant (UV 94-V0). FR4 material is a copper clad laminate made of electronic-grade alkali-free glass fiber cloth impregnated with flame-retardant brominated epoxy resin, single-sided or double-sided copper foil, and hot-pressed.

CEM-3 type material is an electronic grade alkali-free glass non-aromatic cloth, the intermediate insulating layer is filled with flame-retardant brominated epoxy resin, and the non-double sides are filled with flame-retardant brominated epoxy resin. – Woven fabric. The copper foil is on one or both sides of the Resin electronic grade alkali-free glass fiber cloth, and then formed into a copper clad laminate by hot pressing.

Fast Turn PCB Common PCB Laminate and its Manufacturer

Copper clad laminates are also called substrates. The reinforcing material is impregnated with resin, and copper-clad on one or both sides, and is made into a plate by hot pressing, which is called a copper-clad laminate. This is the basic material of the PCB and is often referred to as the substrate. It is also called “core” when it is used in multilayer PCB board production.

Commonly used copper clad laminates are as follows:

FR-1: Phenolic tissue paper; this substrate is also known as bakelite (more economical than FR-2)

FR-2: Phenolic Tissue Paper

FR-3: Tissue paper, epoxy resin

FR-4: fiberglass cloth, epoxy resin

FR-5: glass fiber cloth, epoxy resin

FR-6: frosted glass, polyester

G-10: glass fiber cloth, epoxy resin

CEM-1: Tissue paper, epoxy resin (flame retardant)

CEM-3: Tissue paper, epoxy resin (not flame retardant)

CEM-4: glass cloth, epoxy resin

CEM-5: glass cloth, polyester

AIN: Aluminum Nitride

SIC: Silicon Carbide

The copper clad laminates currently available in the market can be divided into the following categories from the substrate:

- Paper base

- Glass fiber cloth substrate

- Synthetic fiber cloth base

- Non-woven substrate

- Composite substrate

- Other

Copper clad laminate refers to the adhesive sheet (adhesive paper and tape) filled with resin in substrates such as paper and fiberglass cloth. After combining several adhesive sheets, apply copper foil on one or both sides. It is cured by heat and pressure into a plate-like product.

The shielding material refers to a copper clad laminate with a shielding layer or a patterned circuit on the inner layer. As long as the circuits on both sides are processed, it can be a multi-layer circuit board. This is also known as “shielded copper clad laminate”.

Multilayer materials refer to copper clad laminates and adhesive sheets (tapes) used to make multilayer circuit boards. More recently, this has included greased copper foil (RCC) for multilayer laminates. The so-called multi-layer board refers to a circuit board with two layers of patterned circuits on both sides and inside.

Specialty substrates refer to laminates, metal core substrates, etc. used in the additive process and are not included in the speciality board types above.

Metal core substrates also include resin-coated substrates (FBC, etc.) Others are:

- Aluminum core substrate

- Copper core substrate

- Ceramic core substrate

- Glass substrate

Basic knowledge of PCB materials:

Copper clad laminate, also known as PCB substrate.

(1) The reinforcing material (glass fiber cloth, referred to as glass fiber cloth) is filled with resin (pp sheet), one or both sides are covered with copper foil, and the plate-like material formed by hot pressing is called copper-composite layer pressure plate ( Copper Clad Laminate, [CCL]).

(2) The base material of PCB, usually called board.

(3) When used to produce multi-layer boards, it is also called core board (or core board).

copper foil:

(1) The thickness of copper foil is measured in oz (ounces), and oz itself is a unit of mass. Usually, the thickness of copper foil is expressed as “thickness” in terms of mass. The thickness of copper foil is usually defined as “ounces”, 1 ounce copper thickness – one ounce of copper is spread evenly over an area of one square foot. At this time, the thickness of the copper foil is called 1oz copper thickness, and its thickness is exactly 1.37mil (about 1.4mil).

The standard thickness of copper foil is 12μm (1/3oz), 18μm (Hoz), 35μm (1oz), 70μm (2oz).

Process principle of prepreg (prepreg or pp)

pp is a sheet made by filling the treated fiberglass cloth with resin glue and then heat treating (pre-baking) the resin into the B stage. The process principle of the press plate is to use the conversion process of the prepreg from the B stage to the C stage to bond the various circuit layers into one.

Common performance indicators of substrates

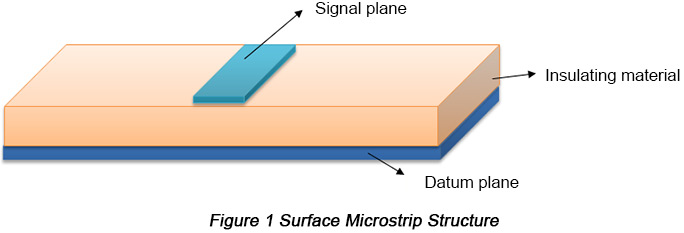

(1) DK: The dielectric constant of the material. Only lowering DK can get higher signal propagation speed.

(2) Df: The dielectric loss angle of the material; the smaller the angle, the lower the signal propagation loss.

Note that DK is mainly related to the impedance of the signal network and also to the capacitance between the plates, and Df is mainly related to the loss of the signal network. Factors that affect DK are:

- Resin (DK of epoxy resin is between 3 and 4);

- Glass fiber cloth (DK is between 6 and 7);

- Resin content (RC value).

(3) Tg: glass transition temperature, which has the greatest impact on vias. The glass transition temperature is a property of polymers and refers to the transition of the resin from hard (glass-like) to soft (rubber-like). This is the temperature at which the shape changes.

At present, the Tg value of FR-4 board is generally 130-140, and in the manufacture of printed boards, there are several process problems beyond this range, which will have a certain impact on the processing effect and final state. product. Therefore, increasing Tg is the main method to improve the heat resistance of FR-4. Tg classification is as follows.

- Ordinary Tg sheet: 130~140℃.

- Medium Tg sheet: 140~150℃.

- High Tg board: greater than 170°C (8-layer PCB board must use high Tg board).

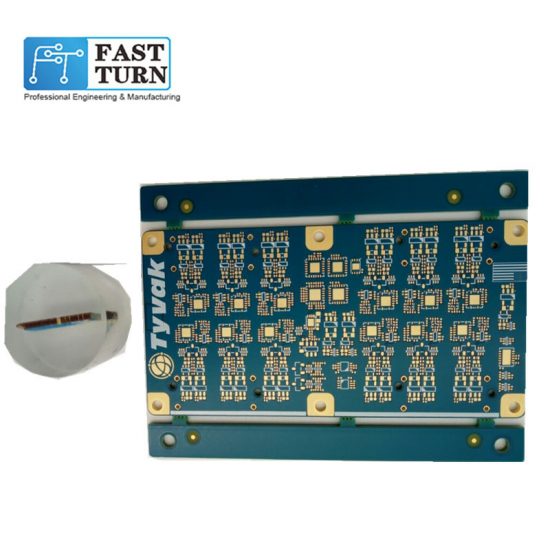

You can view our list of PCB laminate suppliers. We supply these materials for your printed circuit board manufacturing , such as fiberglass epoxy laminates, special high performance laminates, and more. The laminate you choose will depend on your application. If you need assistance in selecting the right material, please contact a Rui Ming Technology enthusiastic customer service representative.

If some of our special PCB materials are out of stock, we can buy them for you – maybe just delaying the need for laminate. Alternatively, you can provide us with materials. We only charge the manufacturing cost. If you have any questions, you are welcome to contact us!

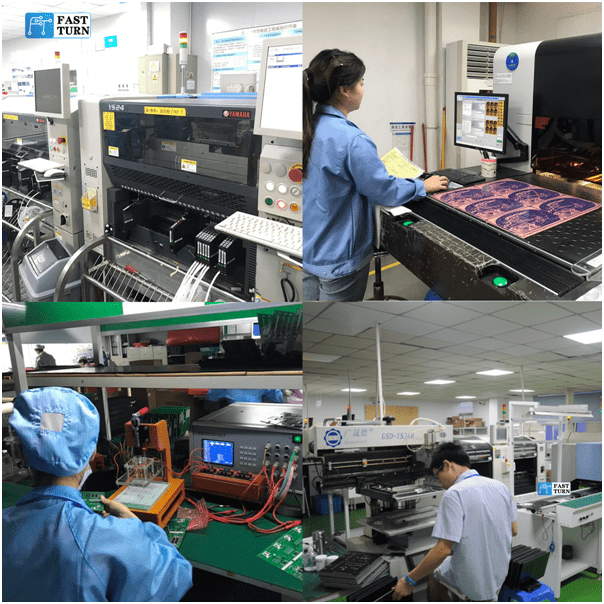

Founded in 2015, The company takes PCB sample manufacturing as the entrance, and has the ability of fast delivery of high-end samples and small and medium-sized batches. Through the whole value chain services such as PCB manufacturing, BOM purchasing and PCB assembly, we provide customers with vertically integrated one-stop solutions for their products. We continue to contribute to the continuous innovation and development of China’s electronic technology, in order to build a first-class electronic product design and manufacturing outsourcing service provider. Pursue the material and spiritual happiness of all staff and make contributions to the progress and development of mankind and society.

We offer professional design solutions covering all aspects of PCB and PCBA layout, including the following board technologies.

Include:

1.PCB design: free laminated design and impedance calculation.

2.PCB manufacturing :PCB board making capacity of 1-48 layers, blind hole, copper thickness up to 12 ounces

3. Component purchase :BOM purchase within 3 days

4.PCB assembly: urgent sample and batch assembly processing, only 1-3 days

5. Functional testing

6. Electronic assembly global logistics

7. Single, double-sided, multi-layer board

8. Rigid circuits, flexible circuits and rigid-flexible circuits.

Please email us to get a quote right away: sales@fastturnpcbs.com

Telephone number: 15018735409