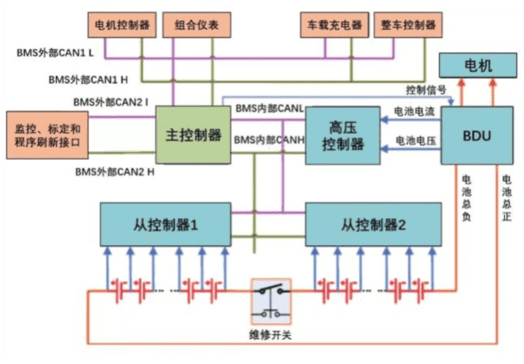

As we all know, the power output of pure electric vehicles depends on the Battery, and the Battery Management System (BMS) is the core of which, which is responsible for controlling the charging and discharging of the Battery and realizing the Battery status estimation. If we compare an electric car to a human body, the battery system is its heart, and the BMS battery management system is the brain that controls its body operation. BMS electrical architecture.

Why BMS?

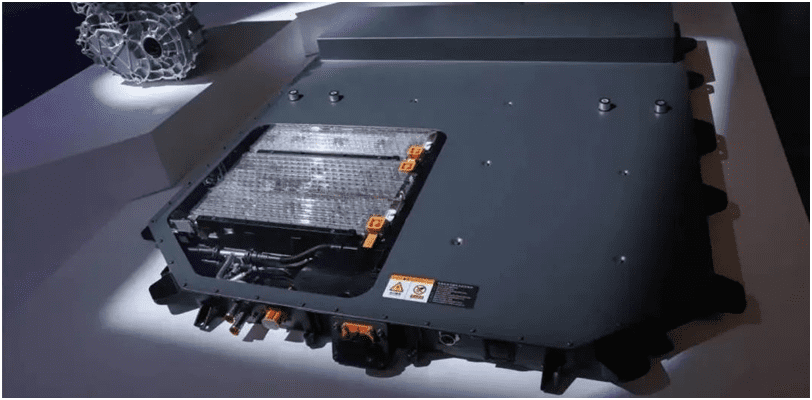

Called a battery management system, the BMS’s main job is to handle tasks related to in-car batteries. Although the current battery manufacturing process has reduced the difference between each cell, but there are still differences in internal resistance, capacity, voltage and so on between a single lithium battery, so in practical application, the internal cells of the battery pack are prone to uneven heat dissipation or excessive charging and discharging phenomenon. Over time, these poorly functioning batteries are likely to fail prematurely, shortening the overall life of the battery pack.

Moreover, the battery in the state of serious overcharge also has the risk of explosion, resulting in damage to the battery pack and a threat to the user’s life safety. Therefore, a targeted Battery Management System (BMS) must be equipped for the power Battery pack of electric vehicles, so as to effectively monitor, protect, balance energy and alarm faults of the Battery pack, and thus improve the working efficiency and service life of the whole power Battery pack.

What are the main functions of BMS?

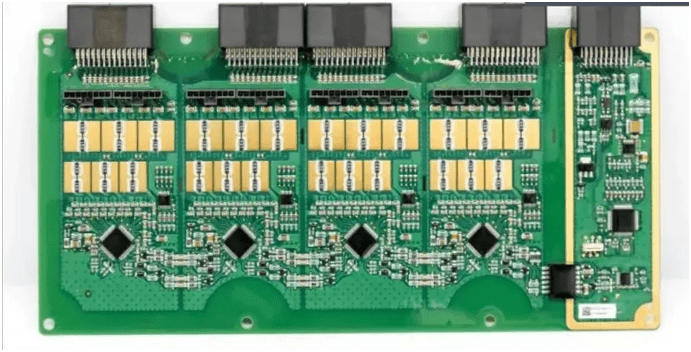

An electric car has hundreds of cells, how does BMS manage? If we look at the anatomy of a battery pack we see that there are hundreds of cells inside, how do you manage that dense battery system? The main work of BMS system is divided into two major tasks — battery detection and battery safety.

The battery detection is relatively simple, mainly through the sensor to collect the battery in the process of using the parameter information, such as temperature, the voltage and current of each cell, the voltage and current of the battery string, etc.. These data play a crucial role in battery pack management. It can be said that without these battery status data as support, battery system management is impossible to talk about.

If we think of the battery testing process as a battery “physical examination,” then the “physical examination” is online, continuous, and uninterrupted. When data is abnormal, you can query the status of the battery in a timely manner and select the faulty battery to ensure the reliability and efficiency of the battery group. After the battery “physical examination” is completed, it will enter the stage of analysis, diagnosis and calculation, and then generate the “physical examination report”, which can be understood as the battery status assessment.

What is SOC?

If you’ve ever driven an electric car, you’ve probably seen the SOC logo on the dashboard. What does that mean? SOC is the State of Charge of a battery pack. SOC is the basis for judging a series of faults such as overcharge and discharge of batteries. Accurately estimating SOC can prevent overcharge and discharge of batteries, prolong the service life of batteries, and improve the utilization rate of batteries.

In fact, in addition to SOC estimation, there are also SOH (State of Health),SOP (State of Power), users can see these data through the vehicle instrument display, so as to confirm the working and functional status of the battery. Accordingly, on the basis of protecting the battery, the potential can be maximized to greatly improve the driving experience.

Accuracy of SOC is important for endurance

SOC algorithm has always been one of the key technologies in the development and application of battery management system (BMS). The accuracy of its calculation directly affects the difference between the apparent endurance and the actual endurance. If the calculation is not accurate enough, the vehicle will even break down when the battery is exhausted.

A series of complex calculations are required to estimate the battery state. That is, to accurately estimate the remaining battery power, ensure that SOC is maintained within a reasonable range, and prevent battery damage due to overcharge or overdischarge, so as to predict the remaining energy of the energy storage battery of hev or the state of charge of the energy storage battery at any time. SOC estimation accuracy is high, for the same amount of battery, can have a higher range. Therefore, high-precision SOC estimation can effectively reduce the required battery cost.

At present, the technical threshold of vehicle standard BMS chip is high, and the suppliers are mainly foreign enterprises. The rapid development of the new energy vehicle industry drives the continuous expansion of the overall market size of BMS, and the importance of BMS chips is becoming increasingly prominent. However, the technical threshold of BMS chip is relatively high. For example, BMS MCU chip requires a large amount of know-how accumulation, and a large number of mature solutions are mastered by NXP and other manufacturers. BMS AFE’s main suppliers are overseas companies such as Ardeno and Texas Instruments. Without long-term research and development and large amount of data accumulation, it is difficult to develop BMS chips that truly meet the requirements of downstream applications.

Vehicle standard BMS chip certification requirements are demanding, certification cycle is long. With the continuous promotion of the national “carbon neutral” strategy, China’s new energy vehicle industry will usher in the golden five years, providing a broad market blue ocean for the application of BMS chips. Before entering into the supply chain system of automobile factories, automobile grading semiconductor enterprises generally need to pass the certification of quality management system IATF 16949 and reliability standard AEC-Q series. After the completion of the certification and review of the relevant vehicle standards and specifications, it is also necessary to undergo rigorous application test verification and long cycle of on-board verification before entering the automotive front assembly supply chain.

Guardian of battery and personnel safety

Another core function of the BMS is to provide safety for the battery pack and crew. As we all know, overcharge and overdischarge of the battery will bring about local overheating, which will affect the battery life, and even threaten the safety of the battery pack, thus causing personal safety risks. At this time, the “charge and discharge management” module of BMS starts the protection function. On the one hand, it communicates with the vehicle and the charger, and on the other hand, it provides the battery status in real time, which is convenient for timely command control and effectively prevents the occurrence of high charge and low discharge.

In the protection of the battery module, balance is also a very important part, is a necessary means to protect and improve the battery life. In addition, the battery protection also includes over voltage, under voltage, over temperature, over current protection. In simple terms, when the actual parameter is higher than or lower than a specified value, the system automatically checks and disconnects or precharges the battery to protect battery safety.

In terms of personal safety, BMS is protected by means of high-pressure control. Battery high voltage can reach 300-500V, far beyond the safety voltage of human body 36V, great risks and hidden dangers, must do a good job of high voltage control, the most common is relay, high voltage interlock, insulation protection. Comprehensive high-pressure protection control can effectively protect the personal safety of drivers, passengers and maintenance personnel.

How to understand the safety level of batteries

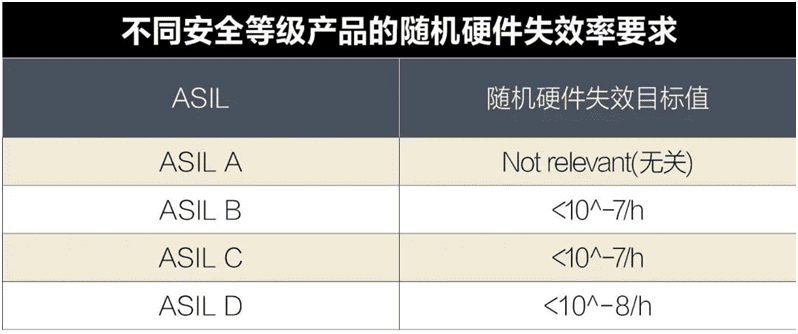

Many domestic battery enterprises use the international general ISO 26262 evaluation standard. And the ISO 26262 standard is based on the degree of Safety risk, divided by A to D Automotive Safety Integrity Level (ASIL), of which D is the highest Level, the most demanding Safety requirements. The higher the level, the higher the security requirements of the system, the higher the cost to achieve security, which means the higher the diagnostic coverage of hardware, the more stringent the development process, the corresponding increase in development cost, development cycle, and technical requirements.

The ASILD rating, with a failure rate of 10^-8/h, means that a vehicle, assuming 4 hours of operation per day, needs 70,000 years of operation to have 1 BMS caused functional failure. Such a low probability of failure is comparable to the requirements of aircraft operation. Generally speaking, the auto industry requires a B or C grade for parts.

Car gauge BMS chips mainly rely on imports

The chips mainly used in BMS include AFE, MCU, ADC, digital isolator, etc. ADI (AFE products are mainly from the acquisition of MAXIM, Linear product line), TI, Infineon, NXP, Renesas (AFE products are mainly from the acquisition of Intersil product line), ST and On Mae and other enterprises can provide a complete solution of BMS chip.

Among them, BMS AFE chip (analog front-end chip) is responsible for collecting battery voltage and converting it to digital value through ADC, and sending it to MCU to calculate the charged state.

In terms of MCU in car regulation, according to incomplete statistics, in recent years, including Jifa Technology, Quan Zhi Technology, Zhaobi innovation, Chip wang Micro, Saiteng Micro, Xiaohua semiconductor, Chipways, Chip sea technology, cloud way semiconductor, chip Wang microelectronics and other domestic manufacturers have chip products have passed the car regulation AEC-Q100 certification.

As for BMS AFE chip, it has the highest technical difficulty and the highest added value, and there are few domestic manufacturers involved in this product. From the public information, BYD Semiconductor has launched a car to meet the AEC-Q100 standard AFE chip; Chipways’ BMS AFE(ASIL-C grade) chip has also been successfully mass-produced.

In addition, SILiconia already has BMS AFE chip products, but mainly used in the industrial field, Xinhai Technology, Siwei, Huatai semiconductor also said that they will develop multiple BMS chips.

In 2021, the number of BMS units will exceed 3 million, among which the top 10 BMS enterprises account for 74% of the market share.

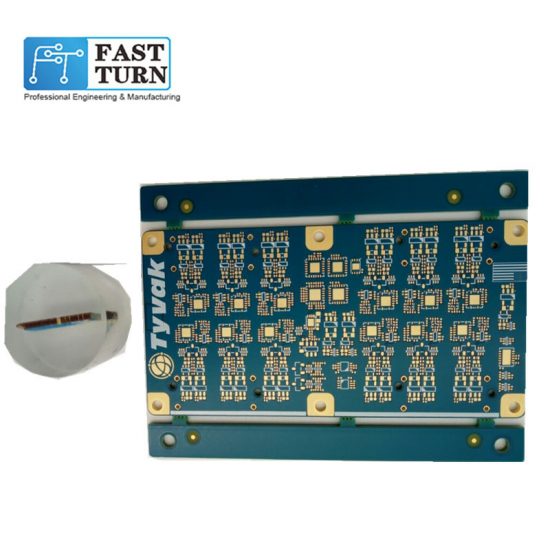

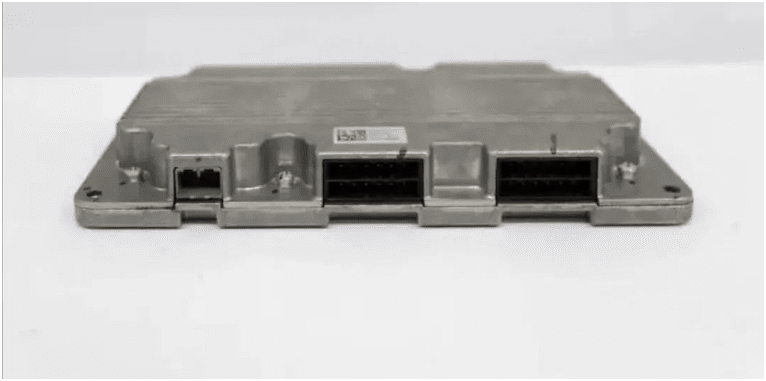

We offer professional design solutions covering all aspects of PCB and PCBA layout, including the following board technologies.

Include:

1.PCB design: free laminated design and impedance calculation.

2.PCB manufacturing :PCB board making capacity of 1-48 layers, blind hole, copper thickness up to 12 ounces

3. Component purchase :BOM purchase within 3 days

4.PCB assembly: urgent sample and batch assembly processing, only 1-3 days

5. Functional testing

6. Electronic assembly global logistics

7. Single, double-sided, multi-layer board

8. Rigid circuits, flexible circuits and rigid-flexible circuits.

Please email us to get a quote right away: sales@fastturnpcbs.com

Telephone number: 15018735409