PCB Assembly Quality Control

Testing and analysis are critical processes in the PCB assembly process. Several tests are required to ensure that the manufactured boards function properly.

Finding a faulty board that does not power on is a nightmare for any company.

To ensure the best performance of the final product, thorough testing is essential in the production of electronic products. That is why the industry employs various testing methods and processes to ensure the proper manufacturing and required functionality and capacity of the PCBs. Here are some of the commonly used testing methods in the PCB assembly process:

- First Article Test

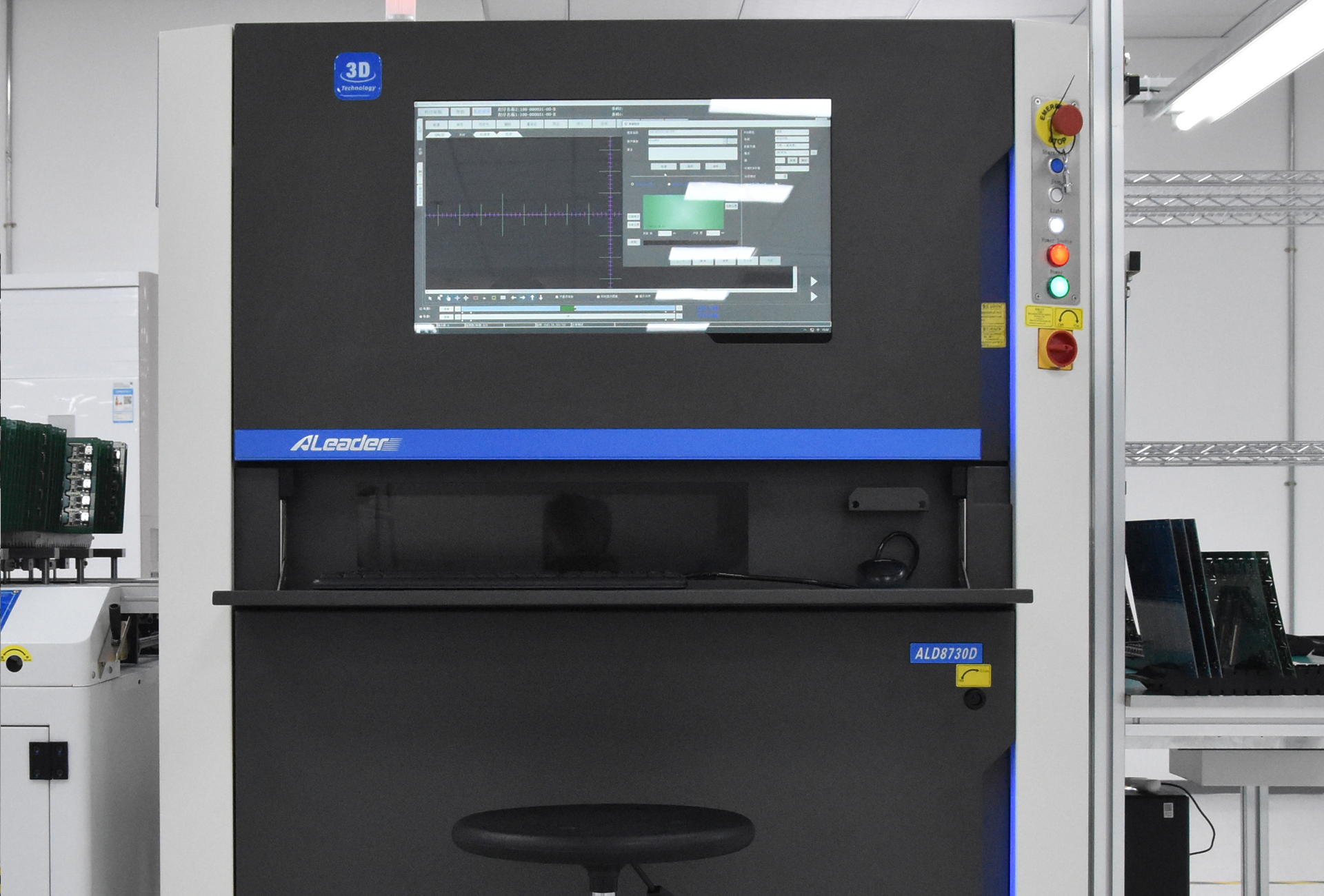

- 3D-AOI

- Aging Test

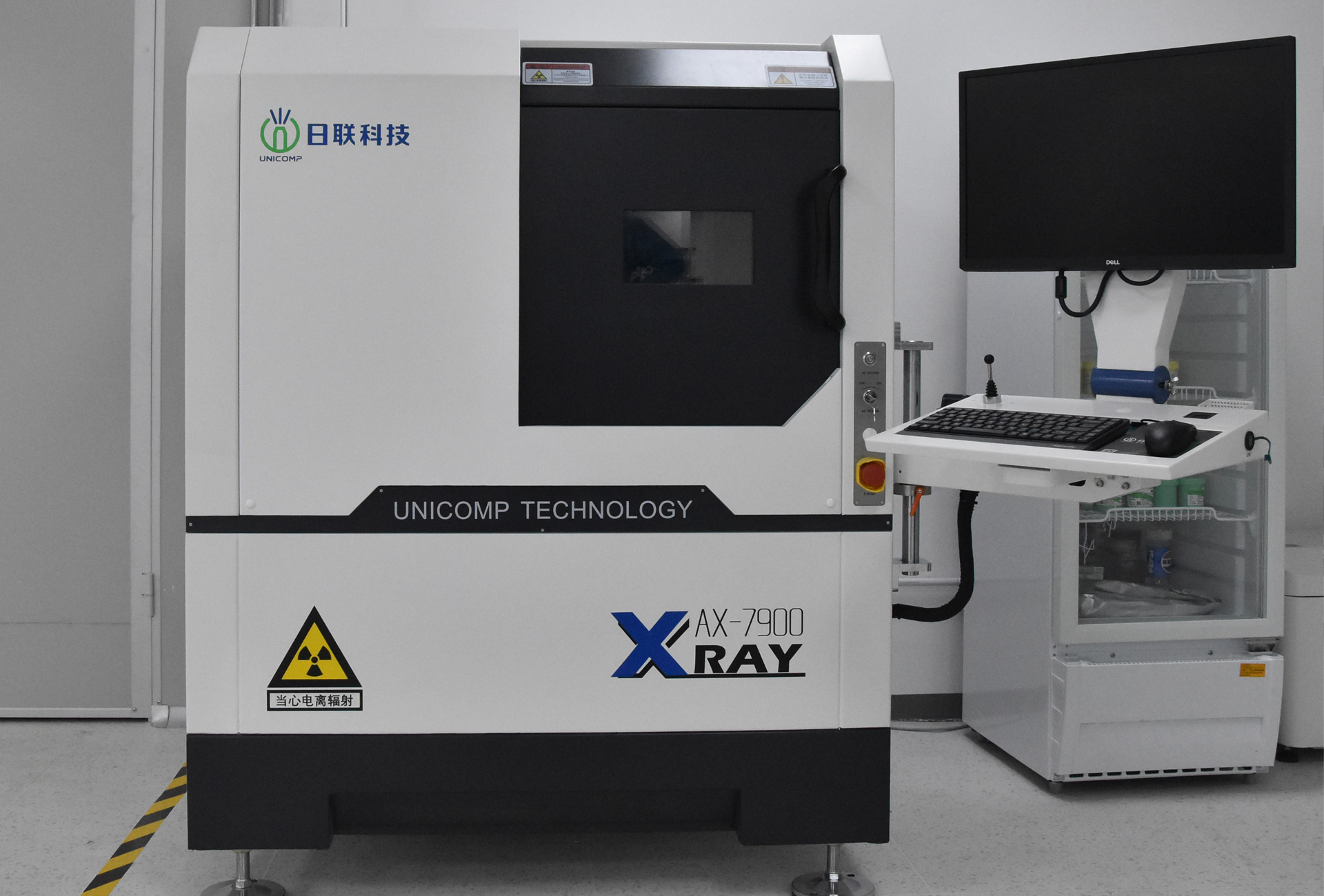

- X-RAY Inspection

- Functional Test

- ICT Test

- FCT Test

Inspection

Equipment

First Article Tester

3D-AOI

X-Ray

SPI Paste Inspection

Samsung & Yamaha High-Speed SMT Machines

GKG Tin Paste Printing Machine

PCB Quality Control

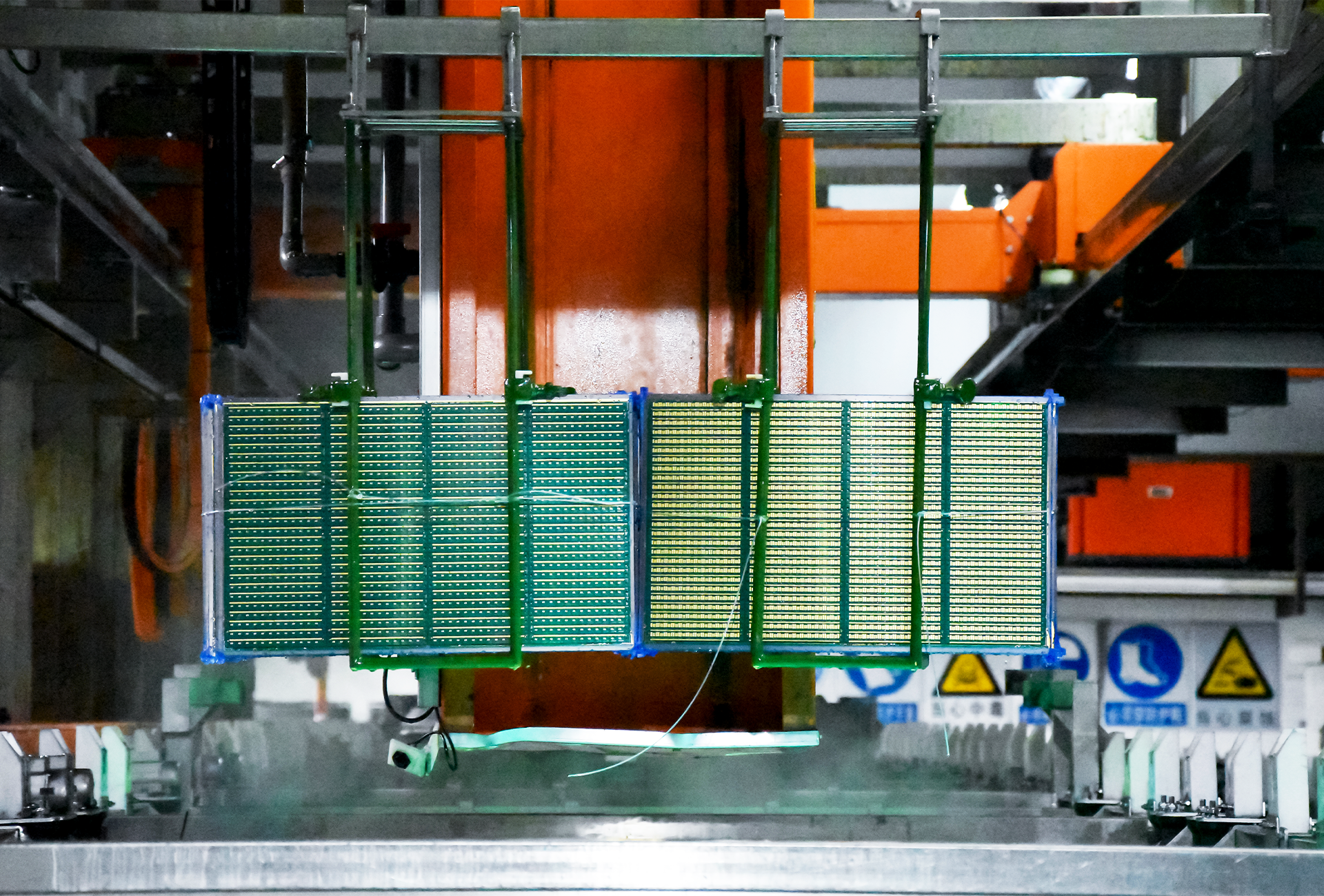

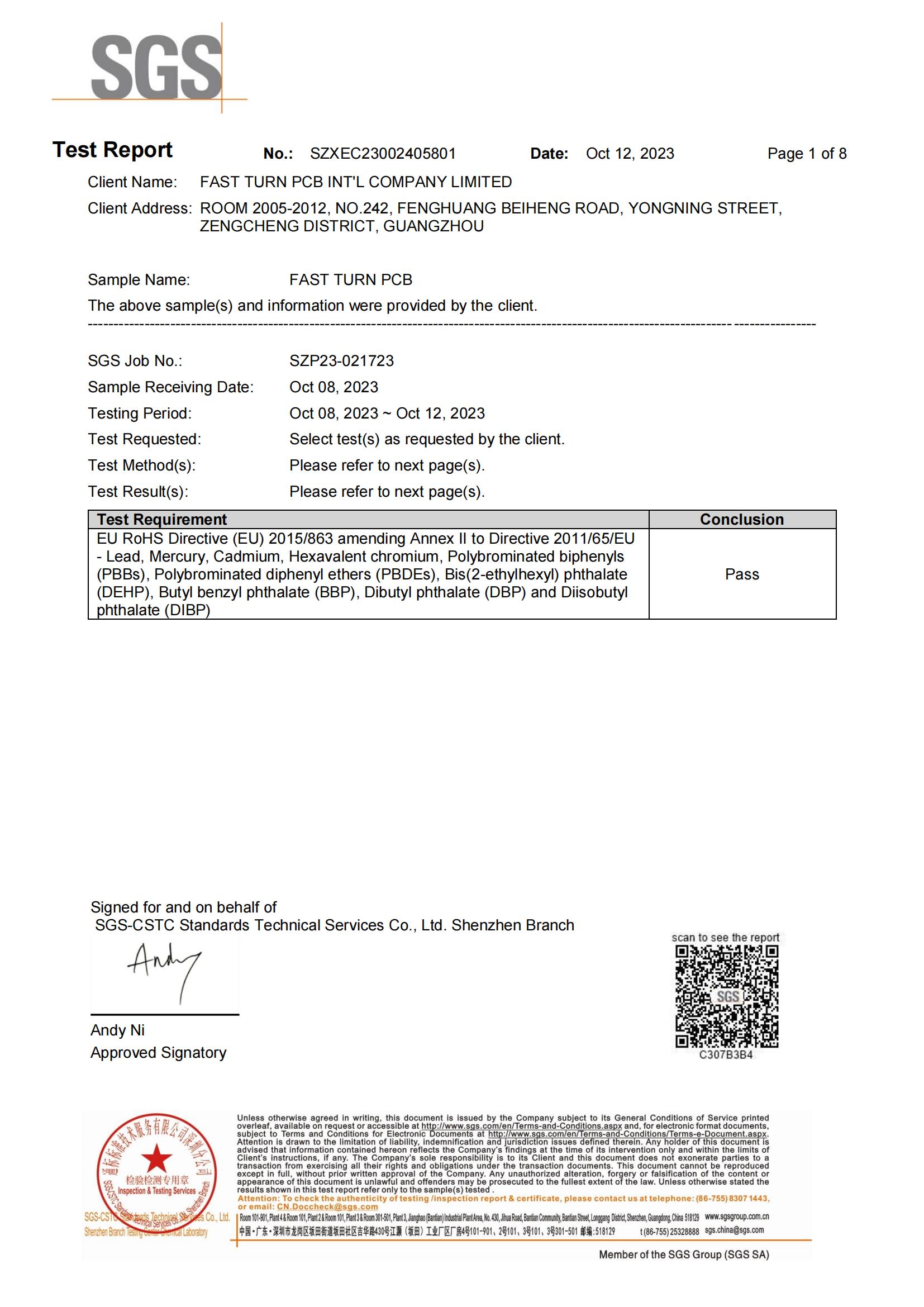

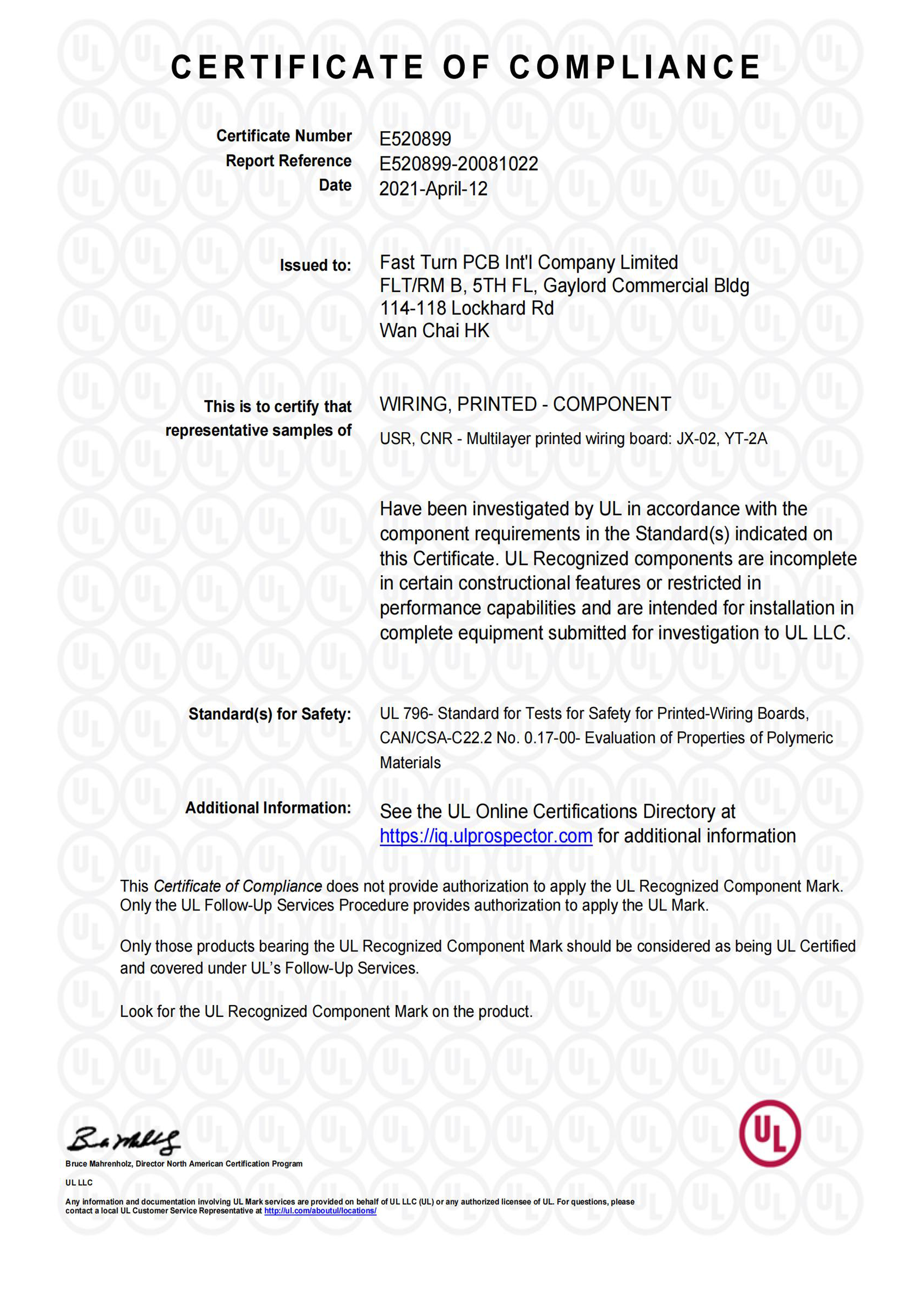

PCB quality control involves strict testing and inspection using advanced tools such as Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and X-ray inspection to detect defects at an early stage.

PCB testing is essential for verifying functionality and detecting defects early in the production process. It ensures that all components are correctly placed and soldered, and the board operates as intended. Through methods like in-circuit testing and X-ray inspection, testing improves product reliability, ensures compliance with industry standards, and reduces costly rework, ultimately supporting high-quality and cost-effective production.

- Microsection

- Solderability Test

- Impedance Control Test

- X-RAY Thickness Meter Test

- Thermal Stress Test

- Ionic Contamination Test

- Peel Strength Test

- Dielectric Voltage-withstang Test

- Insulation Resistance Test

Equipment

Impedance Tester

Four-wire Test

LDI

CNC Routing

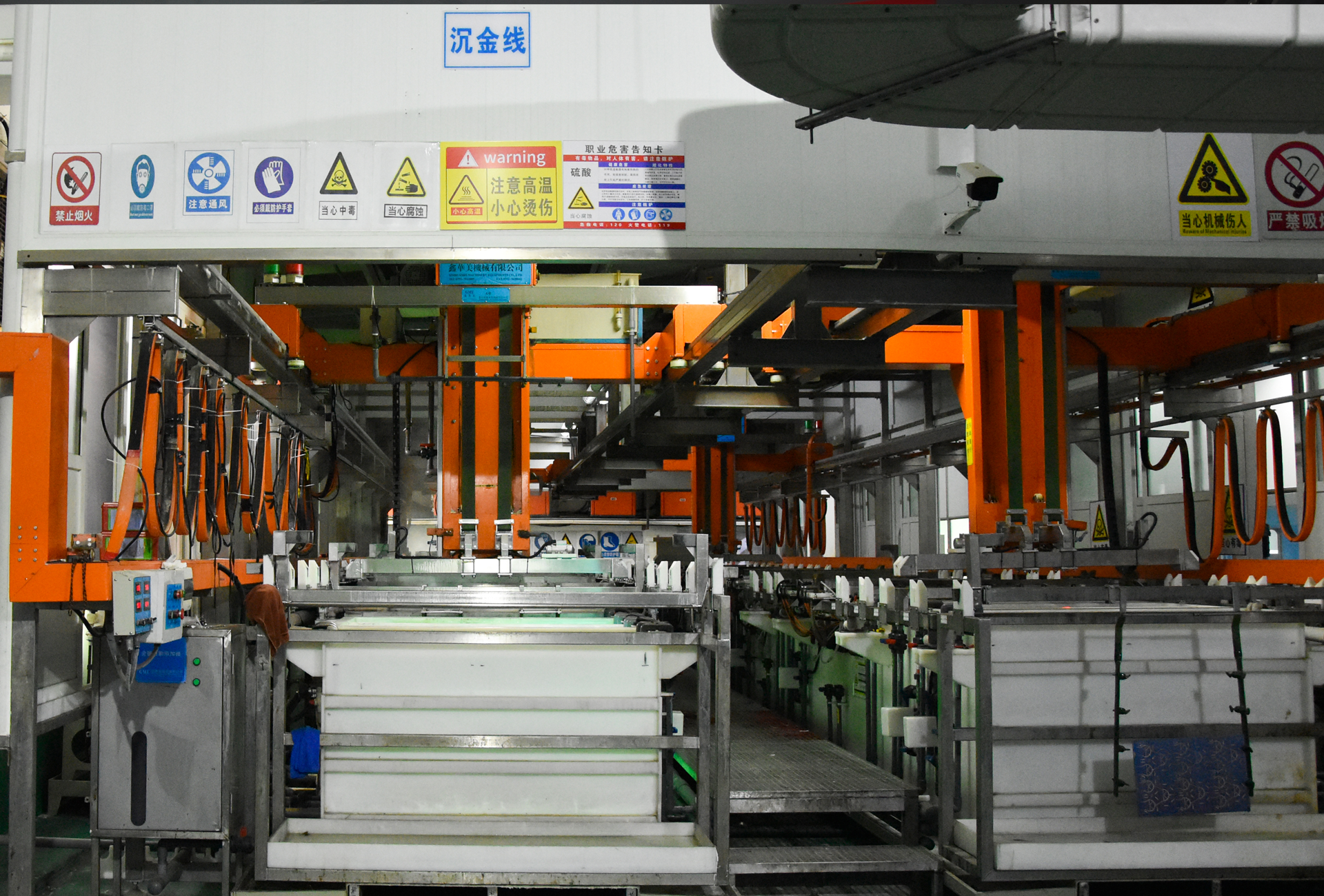

ENIG Line

Six Knife V Cutting Machine

Quality Assurance

_00.jpg)

Put your parts

into production today

All information and uploads are secure and confidential.