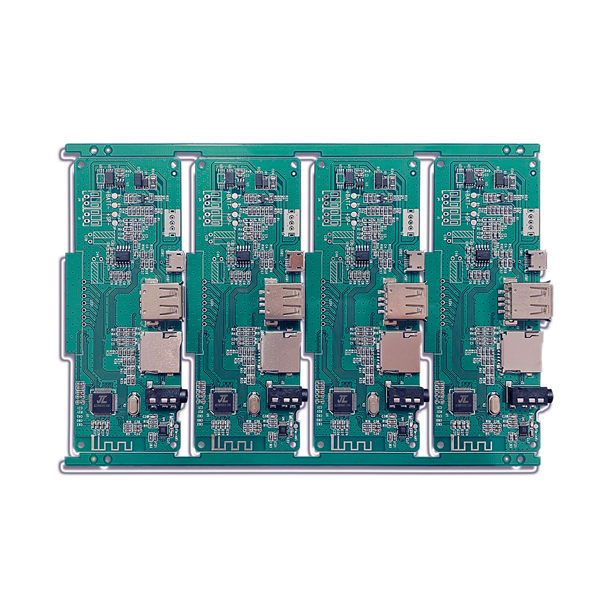

Prototype PCB Assembly

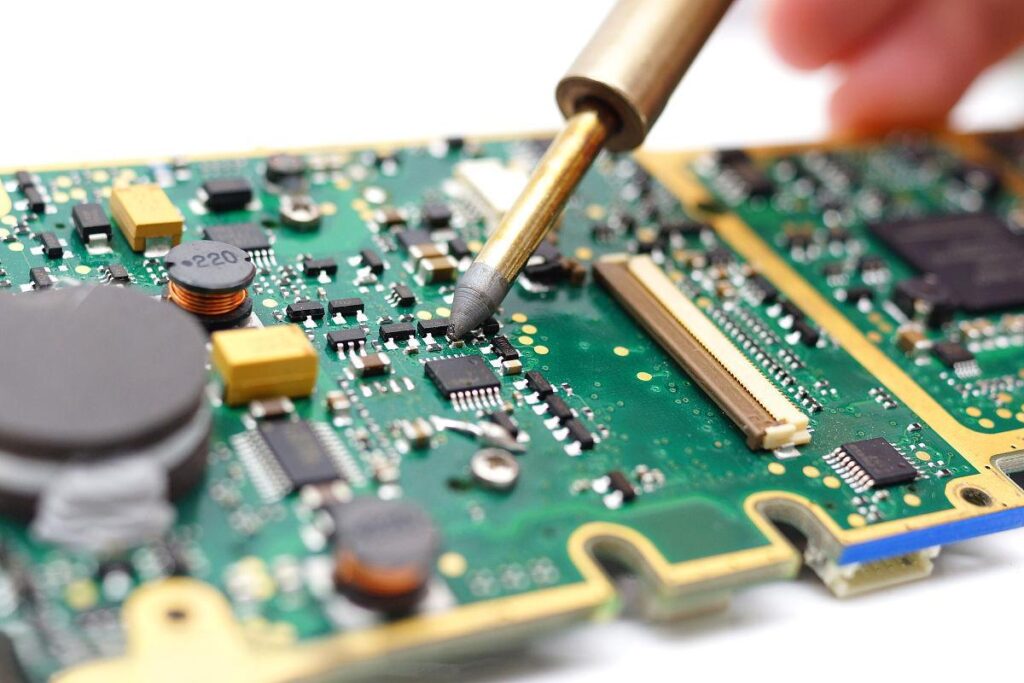

Prototype PCB Assembly manufacturing refers to the precise assembly of electronic components onto customized printed circuit boards based on circuit design drawings, in order to create circuit board prototypes that can be tested and functionally validated.

The main purpose of this process is to verify the feasibility, functionality, and performance of the circuit design, as well as to identify and resolve potential design issues, providing a reliable basis for subsequent mass production.

Our services include Design for manufacturability (DFM) and Design for Testing (DFT) to ensure your prototype will meet your exact design specifications. We can even assemble prototypes for high-density FR-4 circuit boards.

This is Modal Title

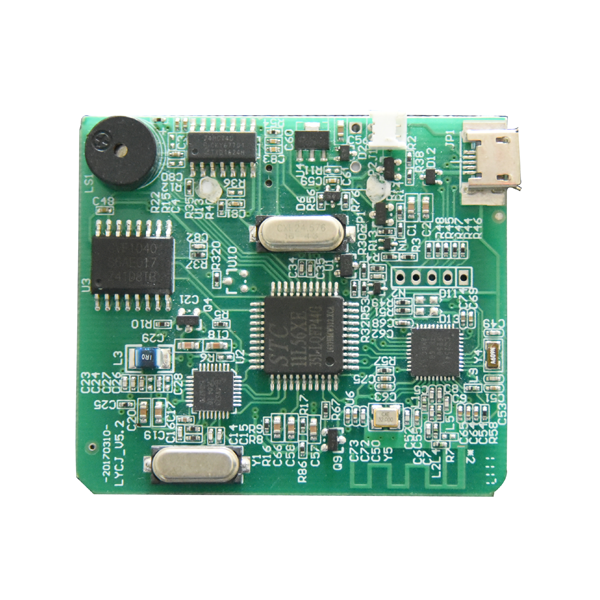

Product Showcase

Capabilities

Capability | Parameter |

Order Quantity | ≥1PC |

Quality Grade | IPC-A-610 |

Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you accurate lead time when we quote for you. |

Size | 50*50mm~510*460mm |

Board Type | Rigid PCB, Flexible PCB, metal core PCB |

Min Package | 01005 (0.4mm*0.2mm) |

Max Package | No limit |

Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Surface Finish | Lead/Lead-free HASL, Immersion gold,OPS etc. |

Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed technology (SMT & Thru-hole) |

Component Sourcing | Turnkey (All components sourced by PCBGOGO), Partial turnkey, Kitted/Consigned |

BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

SMT Parts Presentation | Cut Tape, Partial reel, Reel,Tube, Tray, Laser-cut Stainless Steel |

Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

Stencil | Stencil with or without frame (offered free by PCBGOGO) |

Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

SMT Capacity | 3 Million~4 Million Soldering Pad/day |

DIP Capacity | 100 Thousand Pins/day |

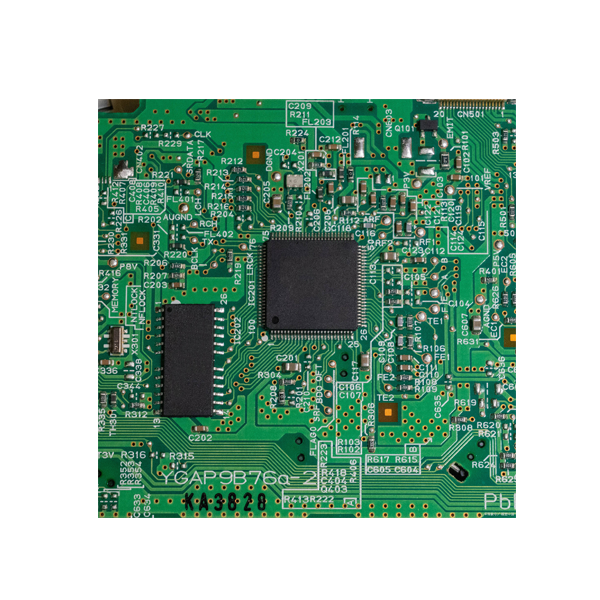

Prototype PCB Assembly refers to the process of precisely assembling selected electronic components onto a customized printed circuit board (PCB) according to circuit design requirements, and producing a prototype of the circuit board that can be tested and functionally verified.

Prototype PCB Assembly is a crucial step in verifying the feasibility, functionality, and performance of circuit design, helping to identify potential design issues and optimize them, providing a reliable basis for subsequent mass production.

Usually includes PCB design and fabrication, component procurement and preparation, manual or automated assembly, testing and validation, as well as possible optimization and iteration steps.

Accurate assembly of components can be ensured through the use of precision welding tools, adherence to strict assembly processes and quality control standards, and the adoption of advanced automated assembly equipment.

Common testing methods include functional testing (to verify whether the circuit is working as expected), performance testing (such as detecting parameters such as voltage, current, and signal integrity), and reliability testing (such as stability testing in high temperature, low temperature, humidity, and other environments).

Top 6 Advantages of Using Flexible PCBs in Product Design

As technology advances, so does the demand for smaller, lighter, and more efficient devices. Engineers and designers are turning to Flexible Printed Circuits (FPCs) to meet these evolving demands. In this article, we explore the top six advantages of using flexible PCBs in product design and how they can significantly improve your projects.

What Is FPC? The Ultimate Guide to Flexible Printed Circuits

In today’s rapidly evolving electronics industry, innovation drives the need for smaller, lighter, and more efficient devices. Flexible Printed Circuits (FPC), also known as flexible PCBs, are essential to this advancement. These highly adaptable circuits allow for complex electronic designs in compact spaces. But what exactly are FPCs, and why are they so important? In this guide, we’ll dive into the details of FPC technology, its applications, and the key benefits it offers.

FPC Flexible PCB vs. Rigid PCB: How to Choose the Best PCB for Your Project

When designing modern electronic products, selecting the right type of PCB—FPC soft board or rigid PCB—is crucial for performance, reliability, and product innovation. In this blog, we’ll focus on the benefits and use cases of FPC flexible PCBs, and offer guidance on how to choose between flexible and rigid options depending on your needs.

Key SMT Process Requirements for Industrial Control Boards: A Comprehensive Guide

Industrial control boards are the core components of automation systems, acting as the "brain" of industrial equipment. Their performance and reliability are critical to overall system stability. The Surface Mount Technology (SMT) process used in manufacturing these boards demands high precision and stringent quality control. This article explores the essential SMT process requirements for industrial control boards across every production stage.

Put your parts

into production today

All information and uploads are secure and confidential.