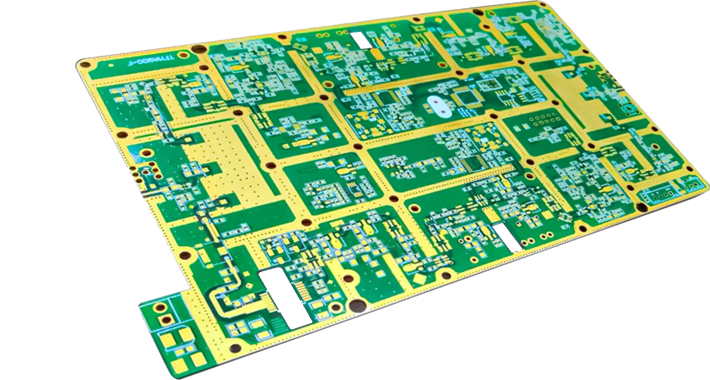

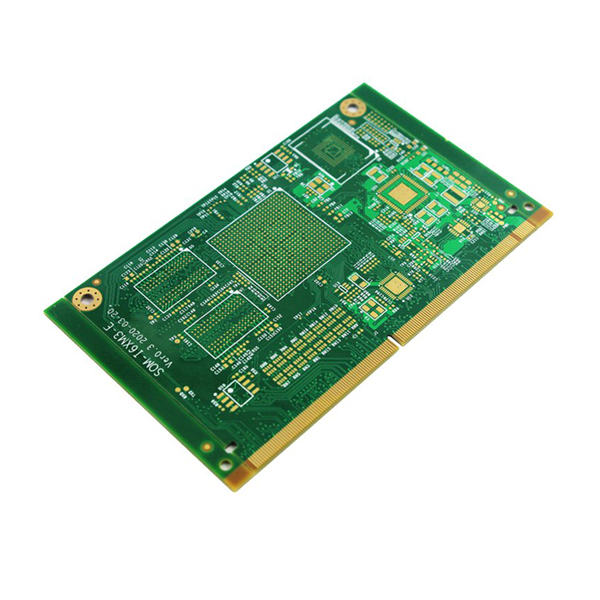

High-Frequency PCB

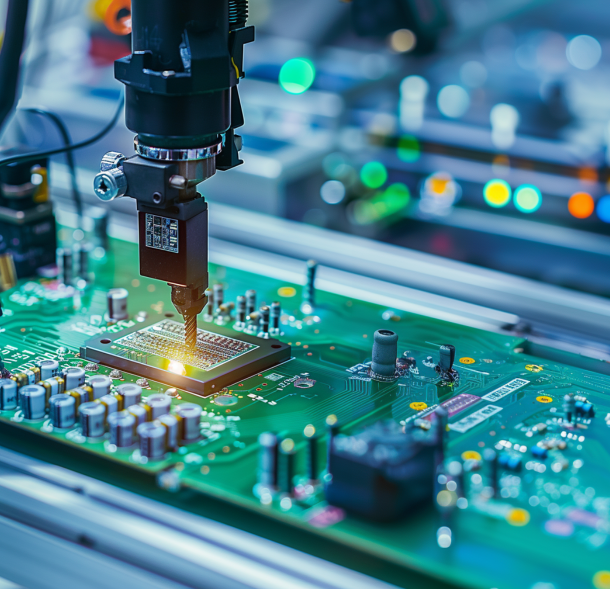

Precision RF & Microwave PCB Fabrication

As a leading China flex PCB supplier, we specialize in high-quality flex circuit manufacturing—from rapid-turn prototyping to full-volume flexible PCB fabrication. Upload your Gerber files now for a fast, reliable quote.

What Is A High-Frequency PCB

Meaning

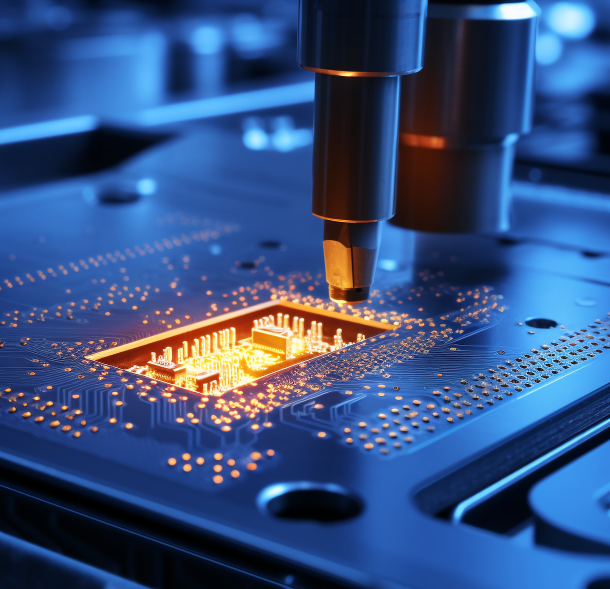

High-frequency PCBs are specially engineered printed circuit boards designed to operate at frequencies typically above 500MHz, and often in the GHz range. These boards are essential for high-speed signal transmission applications such as 5G communication, automotive radar, RF systems, and satellite technology, where maintaining signal integrity and minimizing loss are critical.

Difference

Compared to standard PCBs, high-frequency boards must contend with more complex electromagnetic behavior. Key electrical properties—such as dielectric constant (Dk), dissipation factor (Df), and thermal expansion—must be tightly controlled to ensure consistent signal propagation and minimal distortion.

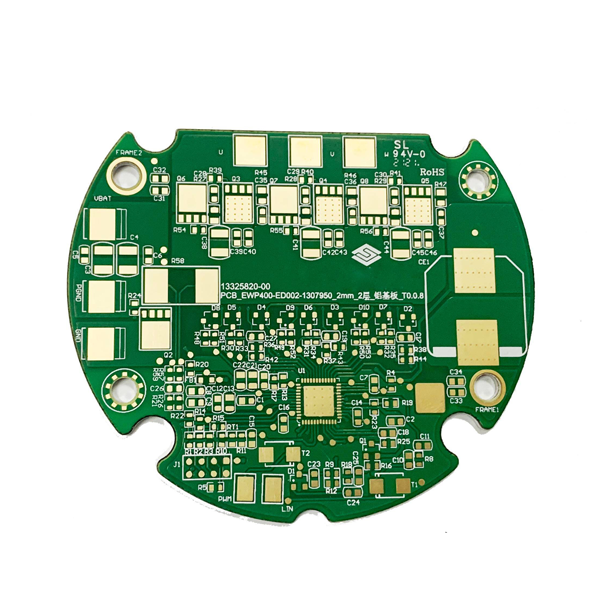

Materials

At Fast Turn PCB, we specialize in manufacturing high-frequency PCBs using materials like Rogers®, Taconic®, Isola®, and PTFE-based laminates, which offer excellent electrical performance, low dielectric loss, and high stability under varying environmental conditions.

Why Are High-Frequency PCBs Important?

As electronic devices operate faster and data rates continue to increase, standard FR4-based PCBs often fall short in maintaining signal performance. High-frequency PCBs help solve these challenges by:

- Turnaround: 24–72 hours for most prototypes

- MOQ: Starting from 1 piece

- Support: Free DFM/DFT check, quick engineering feedback

- Capability: 01005, fine-pitch QFN/BGA, functional test on request

Whether you’re designing a 24GHz automotive radar module or a 5G antenna interface, high-frequency PCBs are a critical fo

Why Choose Fast Turn PCB

we understand that high-frequency circuit boards demand far more than standard PCB manufacturing, from material selection to process control, every detail affects RF performance and signal reliability.

Step 1

Extensive High-Frequency Material Support

We work with a wide range of high-frequency laminates, including:

- Rogers® 4350B, 4003C

- Taconic RF-35, TLY-5

- Isola, Nelco, Panasonic Megtron series

- PTFE, Ceramic-filled, and Hybrid materials

These materials offer excellent electrical stability, low loss, and heat resistance, making them ideal for RF and microwave applications.

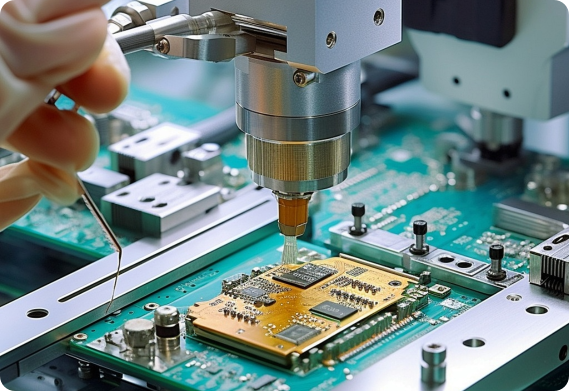

Step 2

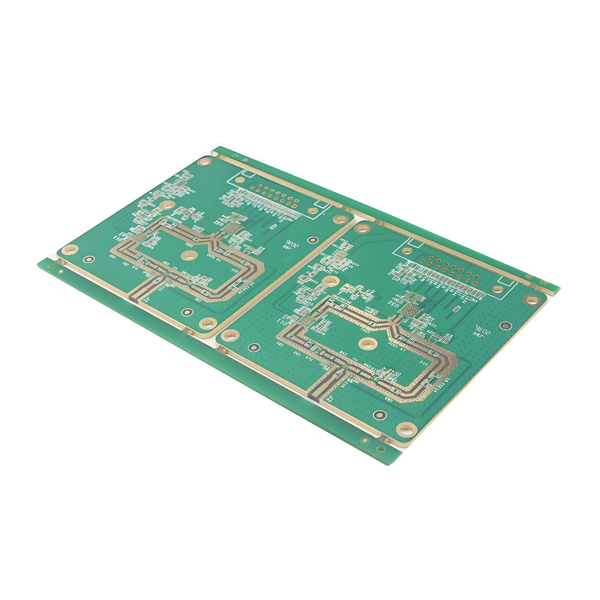

Precision Impedance Control

We provide:

- Controlled impedance tolerance within ±10%

- TDR (Time Domain Reflectometry) testing for verification

- Simulation support for stack-up and trace design

This ensures consistent signal propagation across all frequency ranges.

Step 3

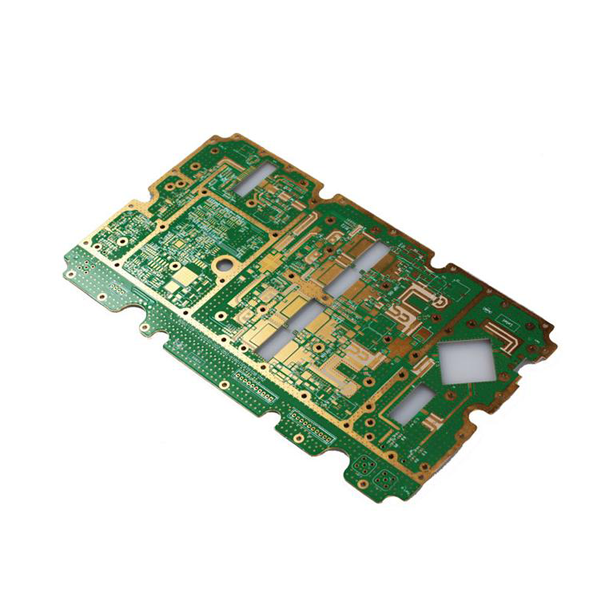

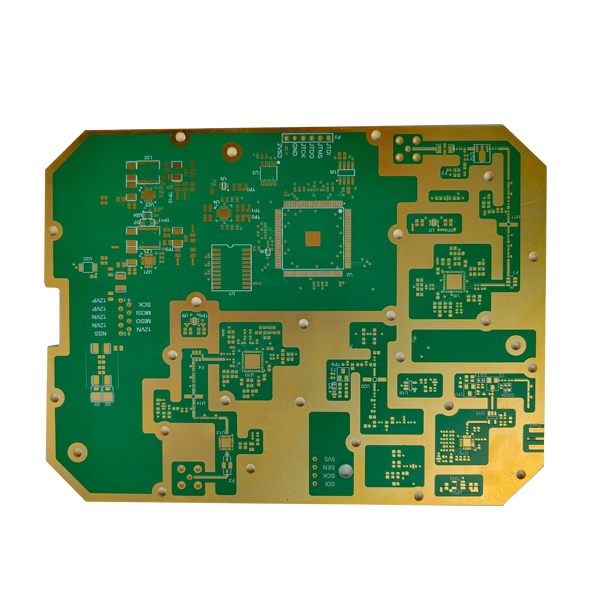

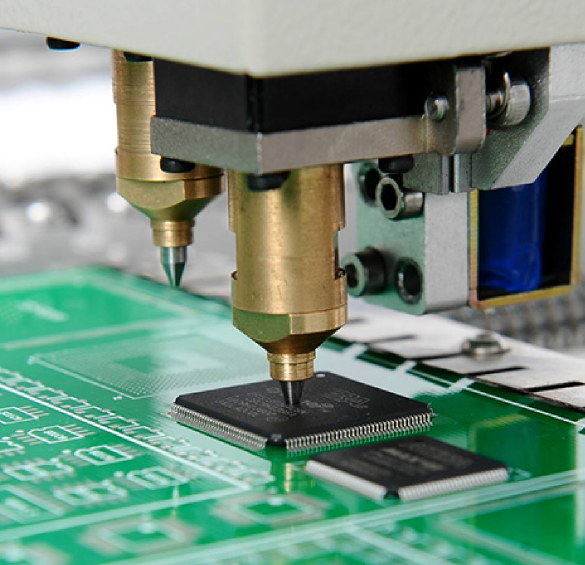

Advanced Manufacturing Techniques

To support high-frequency PCB requirements, we employ:

- Laser and mechanical drilling for microvias and backdrilling

- Low-profile copper foil for reduced skin effect

- High-resolution imaging for fine-pitch traces (as small as 3/3mil)

- Tight registration and layer alignment for multilayer RF boards

Step 4

Reliable Quality and Fast Turnaround

- 100% E-test and AOI inspection on all boards

- Quick prototyping with full production scalability

- IPC Class 2 & 3 compliance for industrial and defense-grade projects

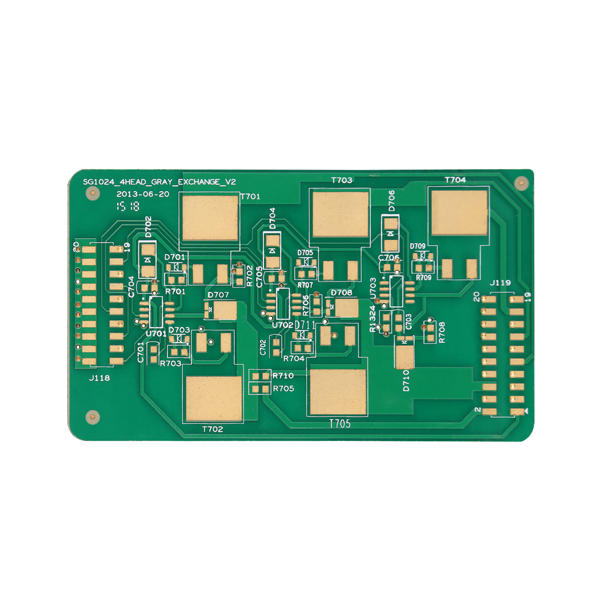

Capabilities

| Capability | Parameters |

|---|---|

| Material |

RO4003C, RO4350B, RO3003, RO3010, RT5880 |

| Min Track/Spacing |

3/3mil |

| Min Hole Size |

0.15mm |

| Finished Cooper |

1-2oz |

| Board Thickness |

0.2-3.2mm |

| Surface Finishing |

Immersion Gold, OSP, Hard Gold,Immersion SIlver,Enepig |

| Finsih Cooper |

0.5-13oz |

| Solder Mask |

Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte Green |

| Silkscreen |

White, Black |

| Via Process |

Tenting Vias Plugged Vias Vias not covered |

| Tenting |

Fly Probe Testing AOI Testing |

| Build time |

7-10 Days |

| Lead Time |

2-3 Days |

High-Frequency PCB Design Tips

Use Short, Direct Signal Paths

Keep traces as short and straight as possible to reduce signal delay and distortion.

Avoid Sharp 90° Corners

Use 45° angles or curved traces to prevent signal reflections.

Minimize Via Usage

Too many vias can cause impedance issues—use them only when necessary.

Maintain a Solid Ground Plane

Ensure continuous grounding under high-speed signals for stable return paths.

Control Impedance Precisely

Match trace width and spacing to your stack-up and material Dk values.

Choose Low-Loss Materials

Select substrates with low Df and stable Dk across temperature and frequency.

Consult Your PCB Manufacturer Early

Collaborate with us to verify your stack-up, impedance, and layout for manufacturability.

FAQ

High Frequency PCBs,

High frequency printed circuit board is a type of circuit board designed specifically to meet the requirements of high-frequency signal transmission.

They use special substrates and manufacturing processes to ensure excellent electrical performance and stability at high frequencies.

This type of circuit board has a wide range of applications in wireless communication, radar systems, satellite communication, high-speed data transmission, and other fields.

Flex PCBs are primarily made from polyimide (PI) or polyester (PET) substrates with copper foil layers. We also use adhesiveless laminates for high-reliability applications. Coverlays, stiffeners (FR4 or stainless steel), and surface finishes (ENIG, OSP) are added depending on the design.

Lead times depend on complexity and quantity:

- Prototype Flex PCBs: 3–7 business days

- Production Runs: 7–20 business days

Expedited options are available for urgent projects — contact us for a custom quote.

- Flex PCBs use flexible base materials and are designed to bend, fold, or twist during use.

- Rigid PCBs are built on FR4 substrates and are not designed for movement.

Flex PCBs save space, reduce weight, and improve durability in dynamic environments.

Absolutely. Our engineering team offers free DFM reviews, helping you optimize your design for manufacturability, cost efficiency, and long-term reliability. Upload your Gerber files, and we’ll evaluate them before production begins.