HdI PCB Manufacturer

Advanced HDI PCB Fabrication & Assembly

As a leading China flex PCB supplier, we specialize in high-quality flex circuit manufacturing—from rapid-turn prototyping to full-volume flexible PCB fabrication. Upload your Gerber files now for a fast, reliable quote.

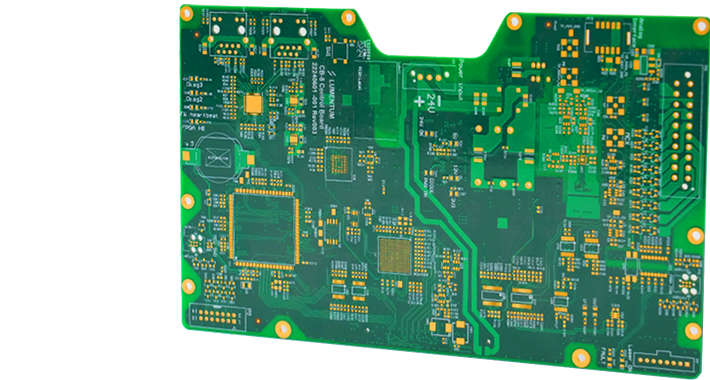

HDI PCB manufacturer

An HDI (High-Density Interconnect) PCB uses blind vias, buried vias and laser-drilled microvias to push routing density and signal integrity to the limit. With sequential lamination and via-fill/plug processes, it delivers more channels, shorter paths and lower crosstalk in a compact footprint.

Core Advantages

- Board-area savings: Microvias and buried vias cut PCB size by over 30%, boosting compactness.

- High-speed performance: Short traces and uniform impedance control support differential rates up to 28 Gbps.

- Flexible multilayer design: Stack 4–32 layers freely for complex layouts and high I/O density.

- EMI/EMC optimization: Shorter return paths and uniform layer distribution effectively reduce EMI/EMC risks.

Core Process Capabilities

Blind & Buried Vias

- Diameter: φ 0.15 – 0.30 mm, tolerance ± 5 µm

- Layer Structures: 2+N+2, 1+N+1, etc.

- Min. Spacing: 0.3 mm (blind) / 0.5 mm (buried)

Laser Micro-Vias

- Diameter: φ 0.10 mm via direct laser drilling, smooth wall

- Depth Control: 1–2 mil (25–50 µm)

- Use Case: Mid-layer interconnects and high

Sequential Lamination

- Stack Options: 1+N+1, 2+N+2, 2+2+N+2+2, etc. ± 5

- Temp/Pressure Control: ± 2° C and ± 0.1 bar

- Layer Count: Fully customizable 4–32

Via Fill & Via Plug

- Materials: Conductive copper paste or epoxy

- Planarity: ≤ 10 µm for consist

- Thermal Boost: Up to 1 oz copper thickness pos

Laser Micro-Vias

- Options: 1–6 oz on inner & outer layers

- Tolerance: ± 10%

- Ideal Use: ≥ 2 oz for high-power or enhanced heat dissip

All parameters can be fine-tuned per project to ensure optimal HDI PCB performance in high-density routing, high-speed signaling, and high-reliability applications.

Capabilities

| Capability | Parameters & Highlights |

|---|---|

| Min. Line Width/Space |

2.5mil/2.5mil (0.063mm/0.063mm) High-density routing, supports 0201-0402 components Trace tolerance ±1µm for consistent signals |

| Max. Layer Count |

Up to 20-layer stack Supports 1+N+1 and 2+N+2 sequential lamination Ideal for complex HDI PCB designs |

| Min. CCL Thickness |

Core laminate copper ≥50µm (0.05mm) Optional high-TG FR-4 and specialty materials Superior mechanical strength and thermal stability |

| Min. Build-Up Thickness |

Per-layer lamination 35µm (0.035mm) Precise temperature and pressure control for flat stacks Enables ultra-thin HDI structures |

| Min. Microvia Design |

Laser microvias φ100µm, pads φ200µm Aspect ratio ≤1:1 Optimized for high-speed differential signal integrity |

| Min. Finished PTH Size |

Finished through-holes φ0.15mm (6mil) Compatible with 0.5mm-pitch BGAs Smooth copper-plated walls for reliable soldering |

| Impedance Control |

Impedance tolerance ±5Ω or ±10% Supports 50Ω / 100Ω differential designs Includes impedance simulation and verification to reduce crosstalk |

| RoHS Certification |

Fully RoHS 2011/65/EU compliant 100% lead-free process Meets environmental and green-supply-chain requirements |

| LeadFree Compliance |

Supports SAC305, SAC405, and other lead-free alloys RoHS & REACH compliant Enhanced thermal-cycle fatigue life |

| Green Material Halogen Free |

Halogen-free (HF) laminates available Low smoke, excellent flame retardancy UL94V-0 rated for sustainable manufacturing |

| Copper Filled Microvia |

Via fill (copper or epoxy) options Post-fill flatness ≤10µm, improves heat dissipation and mechanical strength |

| Stack-Up Capability |

Up to 18-layer HDI stacks Flexible blind/buried via stack options Supports copper weights 1oz-6oz and board thicknesses 0.4-3.2mm |

Industry Applications for HDI PCB

Step 1

Design Verification

DFM/DFT Report: Automated manufacturability and testability analysis to eliminate risks early

Schematic & PCB File Review: Checks packages, vias, power-plane routing, and impedance

Step 2

Prototype

24-48 hr Delivery: Small-batch builds with 100% X-Ray and AOI inspection

Functional Validation: Basic ICT testing to confirm specs before next phase

Step 3

Volume Production

Capacity Assurance: SMT lines at 100k CPH/day, through-hole at 50k CPH/day

End-to-End Tracking: RFID material control, online AOI/ICT, FCT, and full process logging

Step 4

Testing & Quality Control

Online AOI & X-Ray: 100% critical joint coverage, > 99.5% defect detection

ICT & FCT: High-density fixtures simulate real‑world operation

Final Inspection: Optional thermal-humidity aging and vibration tests for

reliability

Step 5

Service Models

Turnkey: One-stop PCB fabrication, parts sourcing, assembly, and testing

Partial Turnkey: Customer supplies key components; we source and integrate the rest

Kitted / Consigned: Customer provides PCB and parts; we handle precise

placement and testing

Step 6

After-Sales Support

Engineering Support: Dedicated engineer throughout, quick response on

design or process issues

Traceability: Full production and test reports with batch tracking and issue

diagnostics

Industry Applications for HDI PCB

FAQ

High density interconnect printed circuit board is a circuit board that uses micro blind hole/buried blind hole technology to achieve high-density interconnect between different copper layers inside.

Compared with traditional PCBs, HDI PCBs have higher wiring density and smaller volume, which can meet the demand for electronic products to develop towards lightweight and high-performance.

In addition, HDI PCBs also exhibit superior performance in signal transmission speed, electrical performance, and reliability.

The manufacturing process of HDI PCBs involves multiple key technologies, among which laser drilling technology, electroplating filling technology, and lamination technology are the most critical.

HDI PCBs are widely used in various fields, especially in miniaturized electronic devices such as smartphones, tablets, and wearable devices.

In addition, with the increasing demand for high-performance and high reliability circuit boards in fields such as automotive electronics, medical electronics, and aerospace

HDI PCBs achieve high-density interconnection between different copper layers inside by using micro blind hole/buried blind hole technology and stacking technology.

Micro blind hole/buried blind hole technology enables wiring to be carried out in a smaller space, thereby increasing wiring density.

At the same time, multi-layer technology stacks multiple thin circuit boards together through multiple lamination and drilling processes, further increasing the number of wiring layers and the installation space for electronic components, thereby improving the overall wiring density.

HDI PCBs have multiple special requirements in the design and manufacturing process.

Firstly, due to the high wiring density of HDI PCBs, advanced EDA software is required for precise wiring during design.

Secondly, it is necessary to strictly control various process parameters during the manufacturing process, such as the aperture size of laser drilling and the filling quality of electroplating holes, to ensure the quality and performance of the product.

In addition, HDI PCBs also have special requirements for testing and inspection, requiring high-precision testing equipment and methods for electrical performance testing, reliability testing, etc.