Home - Services - PCB Manufacturing - Custom PCB Manufacturing Services

Custom PCB Fabrication Services

Custom printed circuit boards built to your exact specs—materials, layer count, board thickness, copper weight, and surface finish. From 1-piece prototypes to small-batch production, we deliver fast quotes, tight process control, and reliable quality.

- All uploads are secure and confidential.

Precision Custom PCB Manufacturing Services?

Custom PCBs are ideal when standard boards can’t meet your design requirements—such as specific materials, stackups, finishes, or special features. FastTurn PCBs provides precision custom PCB manufacturing for prototypes and small-to-medium production runs, supporting industrial, medical, communications, and energy applications.

Every build starts with a DFM review to confirm manufacturability and reduce risk. We then fabricate to your specifications—layer count, board thickness, copper weight, surface finish, solder mask, and special notes—using controlled processes and final verification to ensure consistent quality and reliable delivery.

What Is a Custom PCB ?

A custom PCB (custom printed circuit board) is a board manufactured to meet specific electrical, mechanical, and reliability requirements beyond standard specifications. Instead of choosing a “one-size-fits-all” build, a custom PCB lets you define key parameters, including base material, layer count, stackup, board thickness, copper weight, surface finish, solder mask, and any special construction notes for your product.

Custom PCB fabrication is commonly used when designs must meet tight performance targets, fit into constrained enclosures, handle higher current or heat, or maintain stable performance in demanding environments. It’s also the best option for projects that require controlled impedance, specialized laminates, edge features, or other build details that directly affect function and long-term reliability.

Typical applications for custom printed circuit boards include industrial controls, medical electronics, communications hardware, power and energy systems, automotive electronics, and other products where design requirements vary, and consistent build quality is critical. With the right material and process controls, custom PCBs help improve yield, reduce field failures, and support a smoother transition from prototype to production.

Custom PCB Capabilities

FastTurn PCBs offers a wide range of custom PCB fabrication options so you can match your board build to performance, fit, and reliability requirements—from prototypes to small- to medium-scale production.

- Design & Build Options

- Layer count & stackup intent(rigid, flex, rigid-flex, or HDI when required)

- Board thickness & copper weightto meet mechanical and current-carrying needs

- Controlled impedancefor high-speed signals (available as specified)

- Special build notes,such as cutouts, slots, edge features, and other mechanical requirements

- Materials & Performance Choices

- Standard FR-4for general-purpose designs

- High-Tg materialsfor better thermal stability and lead-free assembly conditions

- Low-loss laminatesfor RF and high-speed applications

- Thermal management builds,such as aluminum-based or metal-core options

- Surface Finishes & Solder Mask

- Surface finishes:ENIG, HASL, OSP (and other finishes by request)

- Solder mask & legend:color options, clear markings, and production-ready identification

Testing & Inspection for Reliable Performance

Testing & Inspection Capabilities

Electrical Testing (E-Test)

Detects opens and shorts to verify netlist compliance and ensure reliable connectivity.Automated Optical Inspection (AOI)

Inspects key features such as traces, pads, and clearances to reduce fabrication defects.Visual Inspection

Checks surface finish, solder mask, silkscreen, and overall board appearance before shipment.Dimensional & Feature Verification

Confirms outline, hole positions, slots, and other critical tolerances match design specs.Microsection Analysis

Validates internal layer alignment, copper plating, and material interfaces in complex builds.Surface Finish & Solderability Testing

Evaluates finish quality to ensure smooth downstream assembly performance.

Quality & Certifications

Quality at Every Step

- Standardized Quality Control Procedures

- Electrical & Dimensional Testing

- Trained Fabrication Technicians

- Full Traceability & Documentation

- Continuous Process Improvement

Certifications

- ISO 9001:2015 – Quality Management Systems

- ISO 13485:2016 – Medical Device Manufacturing

- IPC-A-610 & J-STD-001 – Assembly Workmanship Standards

- RoHS / Lead-Free Compliance – Environmental Regulations

- ANSI/ESD S20.20 – ESD Protection

- SMTA Membership – Industry Standards Participation

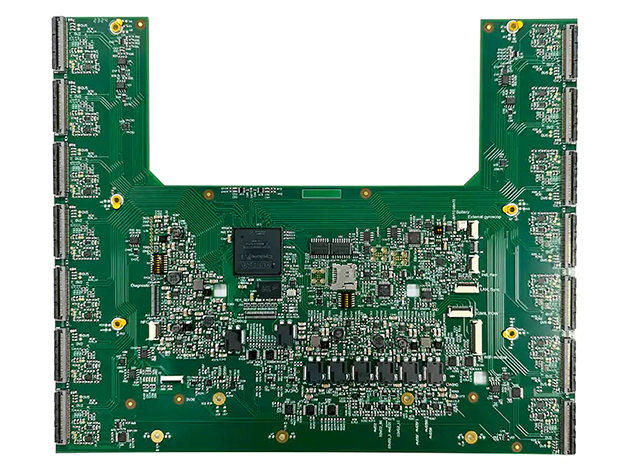

Our portfolio

Our portfolio highlights custom PCB fabrication built for real-world product requirements—from standard rigid boards to complex builds with special materials, finishes, and mechanical features. Each project reflects our focus on building accuracy, consistent process control, and reliable quality across prototypes and small-to-medium production runs.

Prototyping to Production

FastTurn PCBs supports the full product lifecycle—from fast-turn custom PCB prototypes to repeatable, scalable production. Our process is built to help you validate designs quickly and transition to stable manufacturing without changing materials, stackup intent, or quality controls.

Every custom PCB build starts with an engineering review to confirm manufacturability and reduce risk early. As volumes increase, we maintain consistent build parameters and controlled processes to protect performance, improve yield, and keep lead times predictable.

Our Agile Manufacturing Model Supports

- NPI (New Product Introduction)

Structured support for early-stage builds and production ramp-up. - Rapid Design Validation Feedback

DFM-driven recommendations to improve manufacturability and reduce revisions. - High-Mix, Low-to-Medium Volume Production

Flexible workflows for custom requirements and changing demand. - Faster Time-to-Market

Streamlined quoting and production planning for quicker iterations. - Manufacturability Optimization

Continuous process refinement to improve consistency, reliability, and production stability.

Industries & Applications We Support

Industries & Applications We Support

Industries & Applications

- Aerospace & Defense

- Medical & Life Sciences

- Industrial & Automation

- Communications & Networking

- Energy & Power Electronics

- Commercial Electronics & IoT

- Emerging Technologies

Why FastTurn PCB?

Diverse Industry Expertise

We support industrial, medical, energy, communications, and other high-reliability industries, delivering through-hole PCB assembly and mixed-technology PCBA for applications with demanding mechanical and environmental requirements.

End-to-End PCB Assembly Solutions

FastTurn provides end-to-end PCB assembly services under one controlled workflow. Early DFM involvement helps reduce risk and enables a smooth transition from fast-turn prototypes to scalable production.

Turnkey Assembly Services

Our turnkey PCB assembly services include component sourcing, SMT and through-hole assembly, testing, and final integration—simplifying supply chains and improving execution consistency.

Advanced Manufacturing Capabilities

We support complex PCB assemblies through controlled processes, skilled technicians, and flexible assembly lines suited for high-mix and low-to-medium volume production.

Comprehensive Testing & Quality Control

Quality is embedded throughout our PCB assembly process, with inspection and testing methods applied to detect issues early and ensure long-term reliability.

Efficient Lead Times

Streamlined workflows and responsive engineering enable fast prototype turnaround and reliable production schedules without compromising assembly quality.

Inside Our Facilities

FAQ

A custom PCB is fabricated to your exact requirements—material, layer count/stackup, board thickness, copper weight, surface finish, solder mask, and any special notes.

Cost depends on board size, layer count, material, thickness/copper, trace/space, drilling complexity, surface finish, quantity, and lead time. Upload your files for an accurate quote.

Lead time varies by complexity and quantity. Prototypes are usually faster than production runs—submit your files to confirm schedule.

A routing guideline to reduce crosstalk: keep spacing between parallel traces at least 3× the trace width.

Yes—this is PCBA. You’ll typically provide BOM + pick-and-place/CPL in addition to fabrication files.

Looking for an expert quick-turn to turnkey PCB solution?

FastTurn PCB specializes in higher layer count PCBs, quick-turn manufacturing, HDI structures, blind and buried vias, as well as controlled impedance and precision fabrication processes.