Turnkey PCB Assembly Services

Complete Full Turnkey PCB Solutions from Design to Delivery

Our full turnkey PCB assembly service covers everything—from PCB fabrication to component sourcing and final assembly. We handle every step to deliver high-quality, fully assembled PCBs. Upload your Gerbers and BOM now for a seamless, fast quote.

What is Turnkey PCB Assembly?

Turnkey PCB Assembly is a comprehensive one-stop service where the

provider handles the entire PCB manufacturing and assembly process

— from Gerber file review and PCB fabrication to component sourcing,

SMT assembly, testing, and final delivery.

It minimizes your time investment, reduces coordination complexity,

and ensures reliable quality. This is especially valuable for prototype

development, small-batch production, and time-sensitive projects.

Why Choose Turnkey?

All-in-one service saves time

and effort

Professional sourcing team

ensures quality parts

In-house quality control

reduces failure risk

Faster time-to-market and

higher competitiveness

Turnkey vs Partial Turnkey Assembly

What’s the Difference Between Turnkey and Partial Turnkey?

In PCB assembly, Turnkey and Partial Turnkey refer to two service models

The manufacturer handles everything – from PCB fabrication and component sourcing to assembly, testing, and delivery. The customer only provides design files.

The customer provides part of the materials (e.g., components), while the manufacturer handles the rest.

Your choice depends on your resources, time, and supply chain preferences. Here’s a quick comparison

Features

PCB Fabrication

Component Sourcing

Assembly Services

Testing & QC

Client Involvement

Ideal For

Lead Time

Turnkey

Provided by supplier

Fully handled by supplier

Full assembly included

Included (AOI, X-ray, FCT, etc.)

Minimal (hands-off)

Startups, fast prototyping, low ops

Faster overall

Partial Turnkey

Provided by supplier

Partially customer-supplied

Full assembly included

Optional, depends on arrangement

Higher (coordinate parts delivery)

Clients with stock/components in hand

Slightly delayed (waiting for parts)

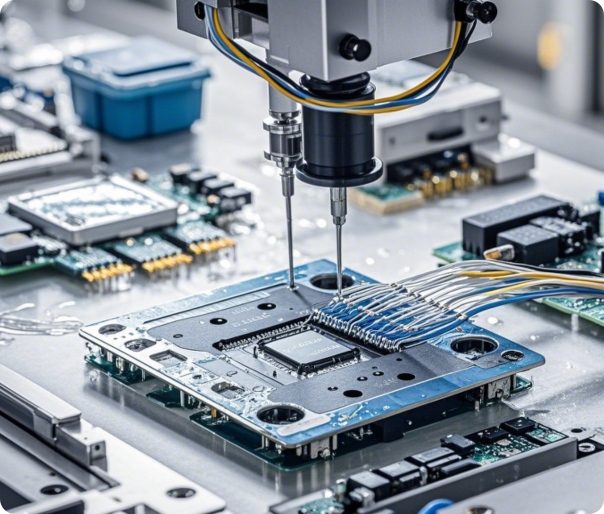

How Turnkey PCB Assembly Works

What Does the Turnkey Process Look Like?

Our Turnkey PCB Assembly service is built around efficiency, accuracy, and transparency. From file submission to product delivery, here’s how it works

Step 1

Submit Your Files

Upload your Gerber files, BOM, and assembly drawings.

Step 2

Instant Quotation

Our team (or system) reviews your documents and sends a quote within 1-2 hours.

Step 3

Component Procurement

We source parts through verified distributors ensuring authenticity and availability.

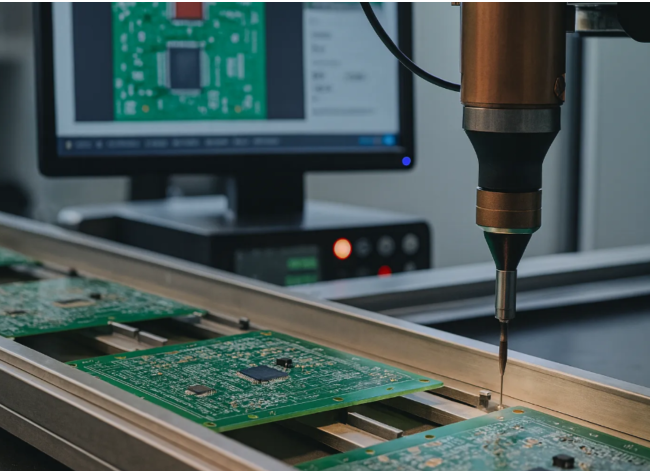

Step 4

PCB Fabrication

Boards are fabricated according to IPC standards, including layer processing, plating, solder mask, and silkscreen.

Step 5

Assembly & Testing

We perform SMT, THT, or hybrid assembly, followed by AOI, X-ray inspection, or functional testing as requested.

Step 6

Packaging & Delivery

Final boards are packed, labeled, and shipped via carriers like DHL, UPS, or FedEx.

Typical Turnaround Time

Rapid Prototypes: 3–7 working days

Standard Batch Orders: 10–15 working days

(May vary depending on BOM complexity and part availability)

Why Choose Our Turnkey PCB Assembly Services

We specialize in delivering practical, engineer-led turnkey PCB assembly solutions for startups, SMEs, and high-reliability applications. Unlike platform-based services, we handle projects hands-on — from BOM review to final delivery — with precision and accountability.

Experienced Engineering Support

Our engineers provide early DFM

analysis, BOM verification, and

process alignment to help prevent

costly rework and improve yield.

Reliable Component Sourcing

We purchase all components via

authorized distributors or customer-

specified sources, ensuring

traceability and authenticity.

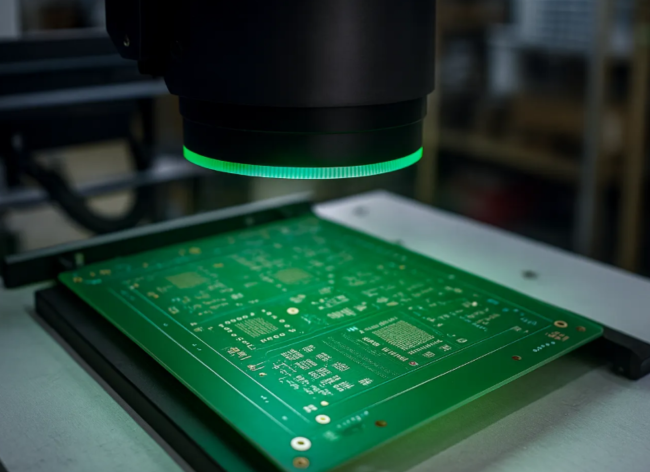

obust Quality Control System

We conduct AOI, X-ray, and

functional testing as needed. All

boards follow IPC Class 2/3 quality

standards.

Responsive & Collaborative Approach

Whether you need quick-turn

prototypes or recurring small-batch

runs, our team ensures fast

communication and well-defined

delivery checkpoints.

We're not a procurement platform — we're an engineering-driven factory directly executing your projects.

Capabilities

| Capability | Parameters |

|---|---|

| Assembly Types |

SMT Assembly( with AOI inspection) BGA Assembly(with X-Ray inspection) Through-hole Assembly SMT & Through-hole Mixed Assembly Kit Assembly |

| Quality Inspection |

AOI Inspection X-Ray Inspection Voltage Test Chip Programming ICT Test; Functional Test |

| PCB Types |

Rigid PCB Metal core PCB Flex PCB Rigid-Flex PCB |

| Component Types |

Passives, Smallest Size 01005(inch) Fine-Pitch Chips to 0.38mm BGA (0.3mm pitch), FPGA, LGA, DFN, QFN with X-Ray Testing Connectors and Terminals |

| Components Sourcing |

Full Turnkey Partial turnkey Kitted/Consigned |

| Solder Types |

Leaded Lead-Free(Rohs) |

| Files Required for Quote and Production |

Gerber RS-274X, 274D, or PCB Design File BOM (Bill of Materials, xls, xlsx) Pick-N-Place file / XY File (for production only) ASSEMBLY Drawings |

| Order quantity |

5pcs to 100,000pcs From Prototypes to Mass Production |

| Assembly Lead Time |

From 8 hours to 72 hours when parts are ready. |

Who We Serve?

We work with a wide range of clients – from startups to industrial manufacturers – all seeking reliable, quality-controlled,

engineer-supported PCB assembly.

Here’s a look at who we serve:

Hardware Startups

Fast prototype + small-run production, aligned with MVP timelines and engineering feedback.

Research Labs & Universities

Precision assembly, custom components, small batch repeats with short lead times.

SMT-based Product Manufacturers

Ongoing orders, BOM assistance, and consistent scheduling.

Medical, Industrial, Smart Hardware Sectors

IPC Class 2/3, RoHS-compliant assemblies focused on reliability and traceability.

How to Choose the Right Turnkey Assembly Partner

Choosing a reliable Turnkey PCB Assembly partner can significantly impact your development timeline, product quality, and overall success.

Engineering Expertise

Do they offer DFM feedback, BOM checks, and Gerber validation? Is technical support responsive and knowledgeable?

Component Sourcing Reliability

Are components sourced through authorized distributors? Do they support customer-specified brands and traceability?

Quality Assurance System

Do they provide AOI, X-ray, and functional testing? Are IPC Class 2/3 standards followed? Are inspection reports available?

Delivery Time & Transparency

Can they commit to timelines per stage? Is prototype-to-production scheduling clearly defined?

Communication & Support

Is project communication proactive and professional? Are engineers available for troubleshooting?

Project Experience

Have they handled similar products or industries (medical, industrial, wearables)? Can they demonstrate relevant experience?

We encourage you to compare - transparency, real engineering support, and reliable quality are why clients stay with us.

FAQ

You’ll need to provide: Gerber files (RS-274X format), a BOM (in Excel or CSV), Pick & Place file (with reference designators), and assembly instructions or drawings if applicable. Our engineers will review your files for completeness.

Yes. We support partial turnkey projects. You’re welcome to supply selected parts; we’ll handle the rest. Please ensure proper packaging (anti-static, moisture-protected) when shipping components.

Absolutely. We support BGA, QFN, LGA, and other advanced packages. Our facility includes X-ray inspection to verify solder joints.

Yes. Our engineers can run BOM checks, identify hard-to-source components, and recommend verified alternates – saving time and reducing procurement risks.

- Prototypes: 3–7 working days.

Standard batch: 10–15 working days.

(Actual time depends on BOM complexity and component availability.)

Yes. If you can supply a test fixture, firmware, or test guide, we can conduct functional tests before delivery.

We comply with IPC-A-610 Class 2/3, RoHS, REACH, and lead-free processes — suitable for industrial, medical, and consumer electronics.