Mass PCB Assembly Services

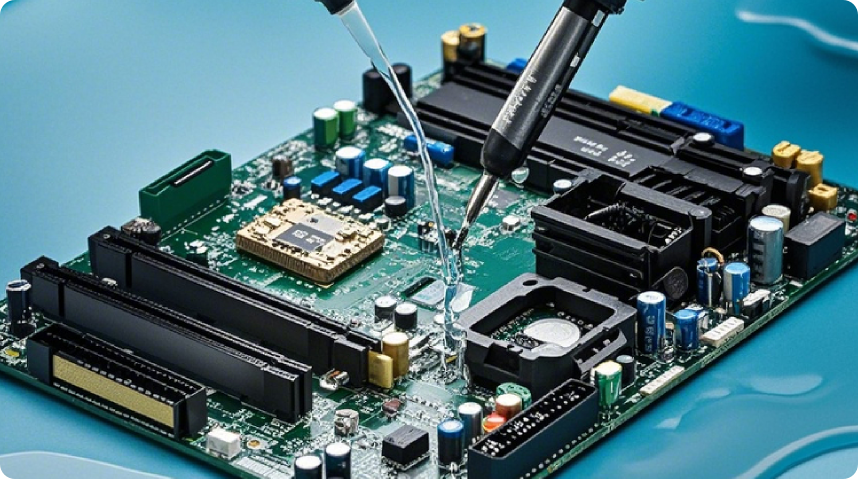

High-Volume PCB Assembly with Precision & Efficiency

We provide expert mass PCB assembly services for high-volume production, ensuring fast turnaround, consistent quality, and cost-effective solutions. From prototype to full-scale runs, upload your Gerbers and BOM now for a competitive quote.

What is Mass PCB Assembly?

Mass PCB Assembly refers to the process of assembling printed circuit boards (PCBs) in large quantities with high efficiency, consistency, and quality.

It is commonly used in the production stage for consumer electronics, automotive, industrial, and medical applications.

Why is Mass PCB Assembly essential?

- Cost Efficiency: Lower cost per unit with volume production

- Consistent Quality: Automated processes ensure uniformity and reduce errors

- Faster Turnaround: High-speed pick-and-place and reflow lines accelerate delivery

- Scalable for Growth: Easily ramp up from prototype to full production

Why Choose Us?

When scaling your product, partnering with the right PCB assembly manufacturer is critical.

End-to-End Turnkey Service

From DFM review and component sourcing to SMT assembly, testing, and packaging - all in one streamlined process.

High-Efficiency Automated Lines

SMT with high-speed pick-and-place, reflow soldering, X-ray inspection, and 3D AOI - ensuring consistent quality at scale.

Scalable Production Capacity

Whether you need thousands or millions of units, we scale flexibly to meet your demands without delays.

Engineering Support That Adds Value

From DFM review and component sourcing to SMT assembly, testing, and packaging - all in one streamlined process.

Certified to Global Quality Standards

ISO 9001, ISO 13485, IPC-A-610, UL, and RoHS compliant – suitable for medical, industrial, and automotive sectors.

Global Component Sourcing

We leverage a worldwide supply chain for strategic sourcing, BOM optimization, and faster lead times.

Process for Mass PCB Assembly

We follow a fully controlled, high-efficiency production workflow to deliver consistent quality and fast turnaround.

1

Data Validation

2

photo-plotting & lmaging

3

Lamination

4

Drilling

5

Copper Platin

6

Etching

7

Solder Mask Application

8

Silkscreen Printing

9

Surface Finish

10

Electrical & Optical Inspection

11

Routing & Profiling

12

Final Inspection & Packaging

Capabilities

| Capability | Parameters |

|---|---|

| Assembly Types |

SMT Assembly( with AOI inspection) BGA Assembly(with X-Ray inspection) Through-hole Assembly SMT & Through-hole Mixed Assembly Kit Assembly |

| Quality Inspection |

AOI Inspection X-Ray Inspection Voltage Test Chip Programming ICT Test Functional Test |

| PCB Types |

Rigid PCB Metal core PCB Flex PCB Rigid-Flex PCB |

| Component Types |

Passives, Smallest Size 0201(inch) Fine-Pitch Chips to 0.38mm BGA (0.3mm pitch), FPGA, LGA, DFN, QFN with X-Ray testing Connectors and terminals |

| Components Sourcing |

Full turnkey Partial turnkey Kitted/Consigned |

| Solder Types |

Lead-Free(Rohs) |

| Files Required for Quote and Production |

Gerber RS-274X, 274D, or PCB Design File BOM (Bill of Materials, xls, xlsx) Pick-N-Place File / XY File (for production only) Assembly Drawings |

| Order quantity |

5pcs to 100,000pcs From Prototypes to Mass Production |

| Assembly Lead Time |

From 8 Hours to 72 hours when parts are ready |

Applications

FAQ

The main advantages include reducing costs, improving production efficiency, ensuring consistency and reliability of product quality, and responding quickly to market demand.

Advanced automatic surface mount machines are usually used to ensure precise placement of components through high-precision machine vision systems and precise mechanical control.

Production defects are usually detected through online inspection equipment and offline sampling. Once defects are found, they will be immediately marked, isolated, and repaired, and if necessary, the production source will be traced for improvement.

Methods to improve production efficiency include optimizing production processes, adopting parallel processing technology, increasing equipment utilization, and reducing production interruptions.

Managing a complex supply chain requires establishing an effective supplier management system, including supplier evaluation, order management, inventory management, logistics tracking, etc., to ensure timely supply of components and cost control.