What Is BGA Assembly?

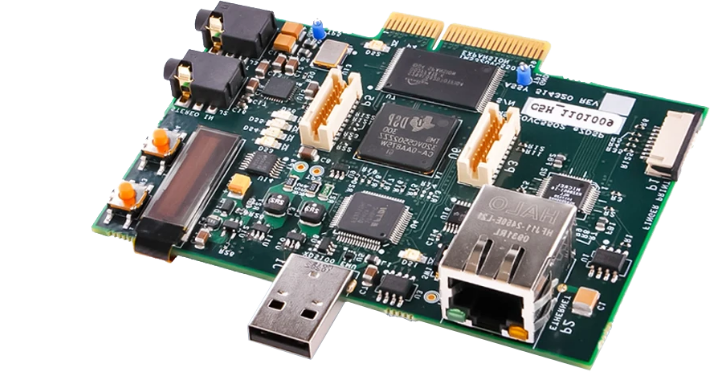

BGA (Ball Grid Array) assembly is an advanced surface-mount technology widely utilized for high-performance electronic component manufacturing. Compared to traditional SMT (Surface Mount Technology), BGA significantly enhances pin density, reduces thermal resistance, and greatly improves overall electrical performance.

What is BGA Assembly?

BGA (Ball Grid Array) assembly is an advanced surface-mount technology widely utilized for high-performance electronic component manufacturing. Compared to traditional SMT (Surface Mount Technology), BGA significantly enhances pin density, reduces thermal resistance, and greatly improves overall electrical performance.

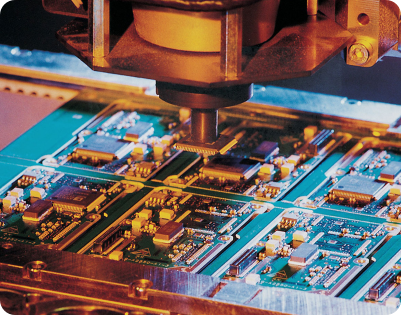

Solder Paste Printing: Precisely applying solder paste patterns onto PCB pads.

01

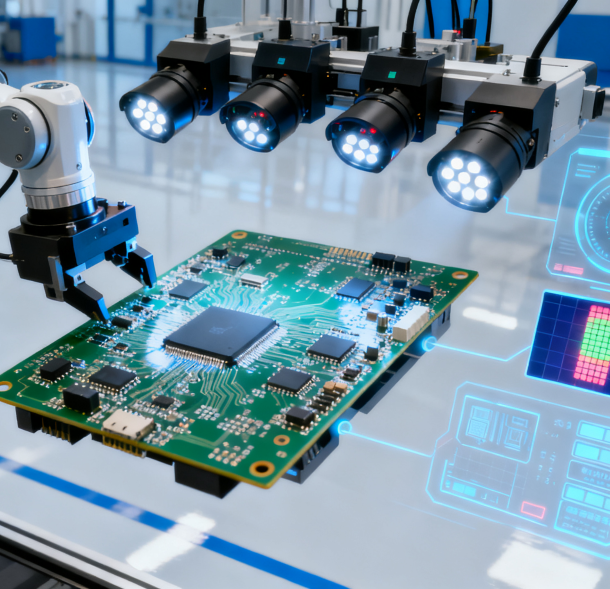

Component Placement: Using automated pick-and-place machines to accurately position BGA chips onto the PCB.

02

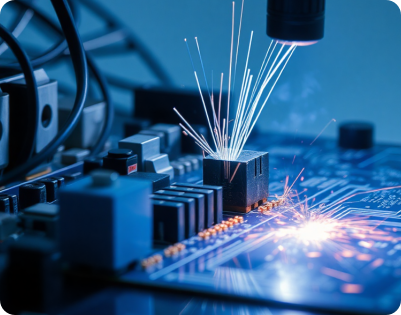

Reflow Soldering: Carefully controlling the temperature profile to melt solder balls, leveraging surface tension for precise auto-alignment.

03

Quality Inspection: Utilizing X-ray and Automated Optical Inspection (AOI) to ensure every joint is robust and reliable.

04

BGA Assembly & Rework Services

Supported BGA Types

- PBGA (Plastic Ball Grid Array)

- CBGA (Ceramic Ball Grid Array)

- µBGA (Micro Ball Grid Array)

- FCBGA (Flip-Chip Ball Grid Array)

- WLCSP (Wafer Level Chip Scale Package)

- Stacked BGA Packages

Technical Capabilities & Specifications

- Minimum Pitch Capability: Our advanced assembly processes handle pitches down to 0.25mm, ideal for high-density, high-precision applications.

- Advanced Placement Equipment: Fully automated SMT pick-and-place machines ensure accurate, reliable component placement.

- Controlled Reflow Soldering Processes: Professional temperature profiling ensures superior solder joint quality and reliability.

- ESD & Temperature-Controlled Environment: All assembly processes are carried out in strictly controlled anti-static, temperature and humidity environments, safeguarding your sensitive electronic components.

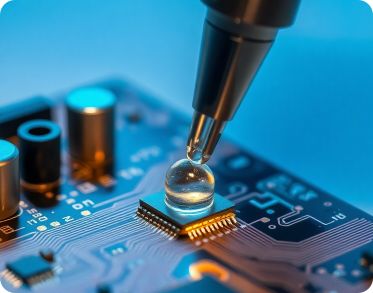

Rework & Reballing Services

- Solder joint repair and component replacement for BGA chips.

- Precise solder ball reattachment (reballing), accurately restoring original solder layouts.

- PCB pad repair and cleaning, extending the lifespan of your circuit boards.

Quality & Inspection

We implement rigorous quality management practices from raw material inspection through final product delivery, ensuring the reliability and stability of every solder joint.

Step 1

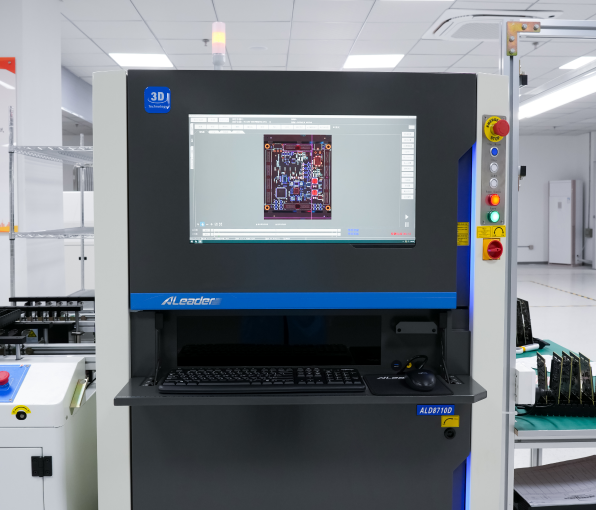

Automated Optical Inspection (AOI)

We utilize state-of-the-art Automated Optical Inspection (AOI) systems with high-precision visual recognition technology to swiftly identify placement deviations, solder defects, and solder joint quality issues, significantly reducing potential failure risks.

- Rapid and accurate detection of component misplacement and missing components.

- Enhanced early-stage defect identification, reducing rework costs.

Step 2

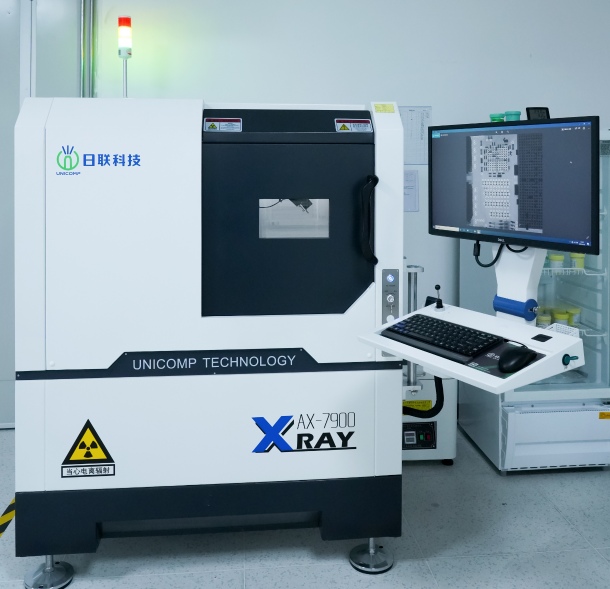

X-Ray Non-Destructive Inspection

Since BGA solder joints are hidden beneath components, we employ high-resolution X-ray non-destructive inspection equipment to visually assess solder joint internal structures, ensuring joints are free of voids, cracks, or inadequate soldering.

- Precise identification of minute internal defects within solder balls.

- Detailed X-ray inspection reports provided to customers, ensuring transparent and traceable production.

Step 3

Design for Manufacturability (DFM) Review

To ensure smooth production of your project, our professional engineering team provides comprehensive Design for Manufacturability (DFM) reviews, covering pad dimensions, solder-mask openings, and soldering process optimization, effectively reducing design flaws and minimizing production risks.

- Expert guidance on optimal BGA pad designs, recommending ENIG finishes and NSMD pads.

- Reduced production costs and increased first-pass yield rates.

Step 4

Strict Production Standards & Certification System

We strictly adhere to international standards such as IPC-A-610 and ISO9001 in our production and inspection processes, ensuring every BGA assembly step meets regulatory requirements and client specifications.

- Compliance with IPC-A-610 Class II and III standards (commercial and military-grade).

- ISO9001 Quality Management System certified, continuously guaranteeing consistent quality.

Industry Application

We understand each industry’s unique requirements and are ready to tackle your most complex technical challenges.

Aerospace

High-density avionics system modules assembly

Medical Devices

Assembly of the medical system module

Telecom

Assembly of Telecommunication System Modules

Automotive Electronics

Assembly of automotive electronic system modules.

Data Centers

Assembly of Data Center System Modules

Quality You Can Trust. Reliable Delivery.

Global Users

Chosen by 9000+ Customers– Your Satisfaction Drives Us Forward.

FastTurn PCB delivers consistent manufacturing quality, fast responses, and dependable delivery for prototypes and mass production. Engineers and OEM teams worldwide rely on us to keep their projects moving smoothly and on schedule.

- US

Great prices, lead times, and quality of work

Great news.Well done,it was fast turn indeed.Your ability to maintain such high standards while delivering ahead of schedule is greatly appreciated. This timely completion has already made a positive impact,Many thanks again for your excellent work.Let's schedule a call next week to discuss the next phase.

DATE OF experience:

July 21,2025

- CA

Completely satisfied with your service and PCBs.

I'm truly delighted with the PCB manufacturing service provided by your company! I checked the PCBs in my design,all specifications meet my requirements perfectly,

I'm completely satisfied with your service and PCBs.

I rate your products and services a perfect 5/5 stars. Thank you for helping bring my electronic designs to life!

DATE OF experience:

May 1, 2024

- UK

Good package with service, price, quality and delivery time.

Tracking number received, Fastturn do a good job!

In the moment I see a good package with service, price, quality and delivery time at

Fastturn, Excels in packaging craftsmanship, service professionalism, cost-effectiveness, product quality, and punctual delivery.Hopefully this will last the next years. Regards.

DATE OF experience:

Apr 07, 2023

- US

Reliable company, outstanding in precision work.

This is tremendous news! Many thanks to you and your team for your dedication and hard work - it's very impressive. I genuinely appreciate your tireless efforts to help us achieve our goals, continuing our productive partnership in future endeavors. Warmest regards and sincere appreciation for making this achievement possible.

DATE OF experience:

Dec 13, 2024

- ISR

We are quire satisfy with your services,thanks.

We received your PCB shipped from Fastturn.We are satisfied with your services. There are no issues with delivery time, circuit board appearance, or packaging.Our team are doing some extra test before making conclusion.Anyway, thank so much for your effort to support us,looking forward to next collaboration. Best regards.

DATE OF experience:

Mar 02, 2024

- SG

We will recommend your company definitely to others.

A pleasant collaboration can be given a score of five

communication: 5 out of 5. Very good communication skills,

leading time: 5 out of 5. The manufacturing time of the PCBs

quality: 5 out of 5. PCB and PCBA quality meets our requirements.

Overall process: 5 out of 5.We will recommend your company definitely to others.

DATE OF experience:

Nov 09, 2024

- US

Well produced,Quick turn,well packaged,fast shipping.

The products are great, really well-made! The whole buying process was smooth and professional, especially how quickly they handled the order. From start to finish, everything worked perfectly—they even packed everything super carefully. You can tell the seller really cares about the details!"

DATE OF experience:

Jul 26, 2024

- US

Received your parts today,they look very good.

Thank you for the expedited shipment - received prototype parts today in perfect condition. Initial inspection appears satisfactory, Your team's remark able speed in both production execution and competitive pricing for this trial order has been impressive. Looking forward to volume production discussions pending test outcomes.

DATE OF experience:

Sept 29, 2024

FAQ

Q:What types of BGA packages can you handle?

Our equipment supports precision BGA assembly down to a minimum pitch of 0.25 mm.

Yes, we offer professional BGA reballing and rework services, including solder ball replacement, solder joint repair, and PCB pad refurbishment.

We employ advanced X-ray inspection equipment to visualize and ensure the integrity of solder joints beneath BGA chips.

Standard projects typically complete within 5-7 days. Quick-turn prototypes can be finished in as little as 24 hours, depending on complexity.

Absolutely! We specialize in prototype and low-volume orders and offer customized solutions for rapid prototyping.

Yes, our engineers offer comprehensive DFM reviews to optimize your PCB layout, pad design, and solder mask for the best production results.

Our processes strictly follow IPC-A-610 Class II and III standards and are ISO9001 certified, ensuring consistent high quality.

Yes, we recommend and frequently utilize ENIG finishes with NSMD pads for optimal solderability and reliability.

Of course! We provide detailed AOI and X-ray inspection reports with every project to ensure complete transparency and traceability.