One-Stop PCB Solutions: No More Fragmented Coordination, 30% Faster to Market

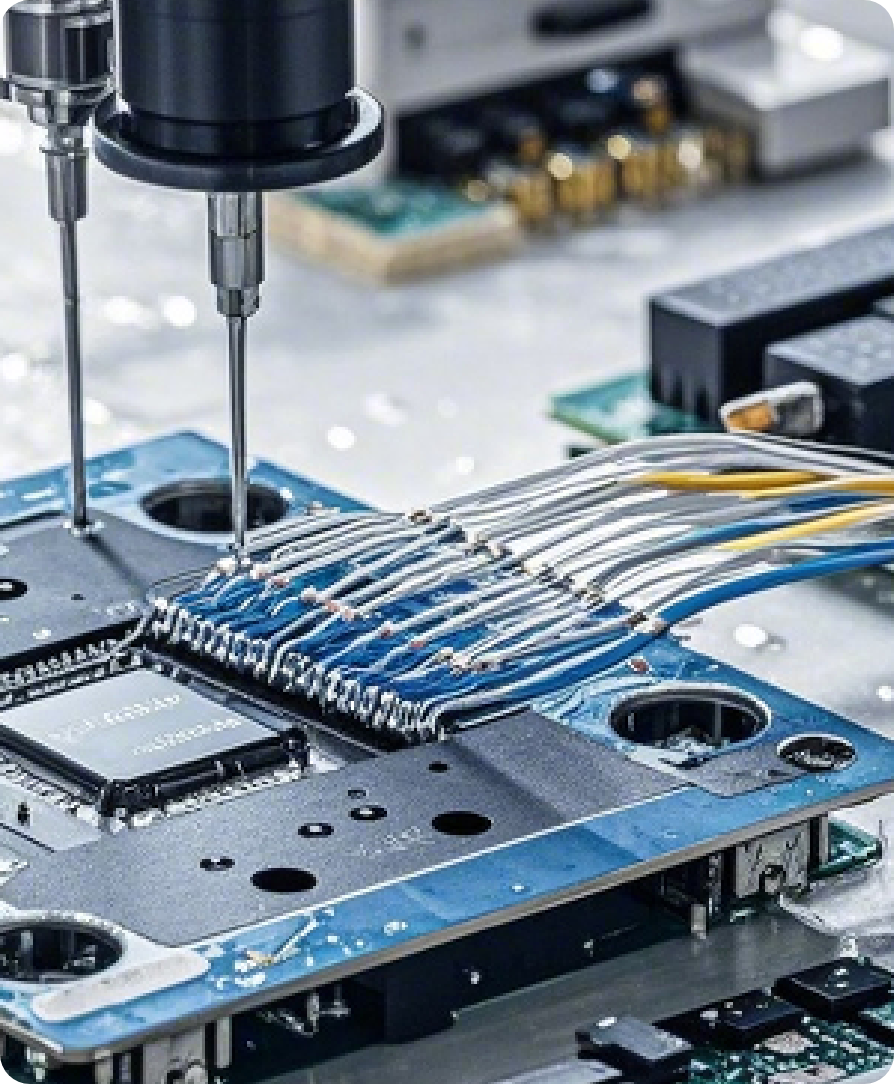

Overview of Advanced Production Equipment

YAMAHA Pick and Place

YAMAHA pick and place machine for automated and precise component placement on circuit boards.

Read More

Circuit Board Cutting Machine

Precision machine for cutting circuit boards to meet production requirements.

Read More

X-RAY

X-ray inspection system for precise internal inspection of solder joints and components.

Read More

Wave soldering

Wave soldering machine for automated soldering of circuit boards with defect-free results.

Read More

Solder Paste Printer

Solder paste printer for precise paste application to ensure reliable soldering.

Read More

Solder Paste Inspection Machine

Solder paste inspection machine to ensure uniformity and quality of paste application.

Read More

Reflow Soldering

Reflow soldering system for precise temperature control to ensure soldering quality.

Read More

AOI

Automated Optical Inspection for accurate defect detection on circuit boards.

Read More

Aivs

Automatic Inspection System for precise component detection and placement.

Read More

What can we do?

PCB FAB

Learn More

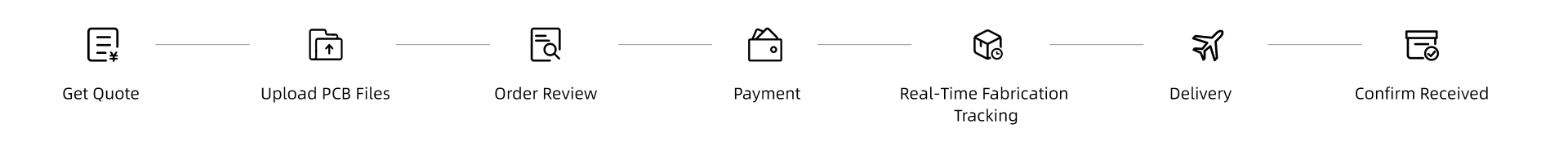

how fast turn works for pcb assembly

Certified Quality

- SMT, THT and Mixed assembled technology

- Single/Double sided assembly

- Lead-free (RoHS compliant)

- Low-Temperature Soldering for Flex PCBs

- Box Build Assembly

Component Types

- 01005 chip size

- 0.3mm BGA spacing

- 0.25mm fine-pitch ICs

- Automotive-Grade Components (AEC-Q Certified)

- Turnkey, Consigned, Partial Turnkey

PCB Types

- Rigid, Flex PCB, Rigid-Flex PCB

- HDI with Blind/Buried Vias (Up to 32 Layers)

- Ceramic/Metal-Core Substrates

- RF/Microwave PCBs (±5% Impedance Control)

Inventory Management

- 20+ SMT Lines (Prototype to Mass Production)

- Daily Capacity: 10M SMT Joints, 180K DIP Joints, 50+ Designs

- High-Precision Siemens SMT, GKG-G5 SPI, EAGLE 3D AOI

- AI-Driven Dynamic Production Scheduling

- MES System for Real-Time Yield Monitoring

Certified Quality

- SMT, THT and Mixed assembled technology

- Single/Double sided assembly

- Lead-free (RoHS compliant)

- Low-Temperature Soldering for Flex PCBs

- Box Build Assembly

BOM Cost Optimization

- Professional BOM optimization including alternates, lifecycle alerts, and cost-down suggestions

- Reduce BOM costs by 15-30% through cross-industry bulk purchasing

- Reduce BOM costs by 15-30% through cross-industry bulk purchasing

Rapid Procurement Process

- 24-Hour BOM Review & Component Matching

- Intelligent Alternate Part Recommendations (>99% Compatibility)

- Emergency Order Service (72-Hour Global Delivery)

Inventory Management

- Smart Warehouse (300K+ SKUs, Humidity/ESD Controlled)

- JIT (Just-in-time) Inventory for Cost Reduction

- Safety Stock Alerts for Critical Components

Technical Support

- Free DFM/DFA Analysis and 24H customer support

- Live dashboard: Real-time yield rate (≥99.2%) & station alerts

- IC Programming, Functional Testing

PCB & PCBA Inspection

- Flying Probe/fixture testing

- IQC, SPI, Online AOI, Offline AOI, IPQC, X-Ray

- IC programming, functional test

Quality Certification

- ISO 9001/14001/45001/13485, IATF 16949, UL Certified

- IPC-A-610 Class 2/3 Standards

- Customized QCP (Quality Control Plan)

Continuous Improvement

- Monthly Quality Reports (CPK ≥1.67)

- 6 Sigma Process Optimization

- Full-Process SPC Data Transparency

Flexible Production

- 24-Hour Prototyping (1-50pcs)

- Small Batch (<500pcs) in 3 Days

- Mass Production (Daily 10M+ Joints)

Logistics Optimization

- In-House Logistics, DHL/FedEx, DDP

- Smart Customs Clearance (<2 Hours)

- PCB-PCBA <300m distance: Panel→assembly in 4hr

Delivery Commitment

- Real-Time Tracking

- Live system monitoring ensures 98% on-time delivery rate

- Contingency Plans for Extreme Scenarios

After sales service

- Response within 2 hours

- Provide solutions within 2 days

- Monthly report and improve

Why Choose Fast Turn?

Certified with international standards, our end-to-end three-level quality management system utilizes authorized original materials to ensure product quality compliance with global benchmarks.

By leveraging bulk raw material procurement and integrated factory operations, we utilize fully

automated SMT production lines to achieve cost reduction and efficiency enhancement.

We offer 72-hour rapid prototyping and flexible delivery services, supporting both small-batch

trial production and medium-volume orders with full engineering technical support throughout

the process.

We provide dedicated one-on-one project manager support, 24/7 online technical assistance, and

full life-cycle quality traceability.

Awards & Reviews

“Their Rogers-Based 800G PCB Achieved Excellent Impedance Control. The premium dielectric properties of Rogers substrates are key to this reliable electrical performance.”

USA

fast turn team have become an invaluable supplier for our prototyping process. Their response time is quick, their prices and lead times are great, and the products…

Jakarta, Indonesia

Authoritative Certification

We have obtained many authoritative certificates, and we can also conduct certification testing for your products, helping your products reach the market faster.