Introduction

In modern PCB manufacturing, surface finish is more than just a protective layer—it directly impacts solderability, reliability, signal integrity, and compliance with environmental standards like RoHS.

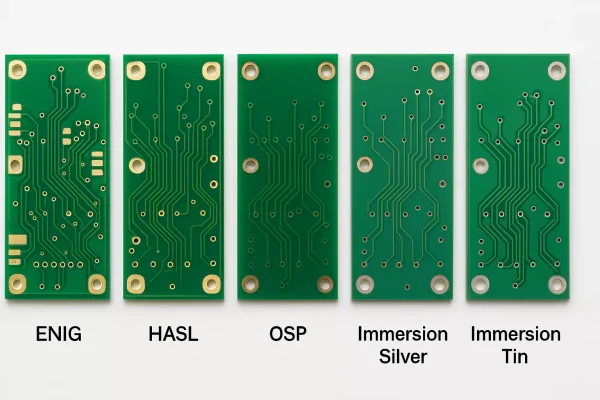

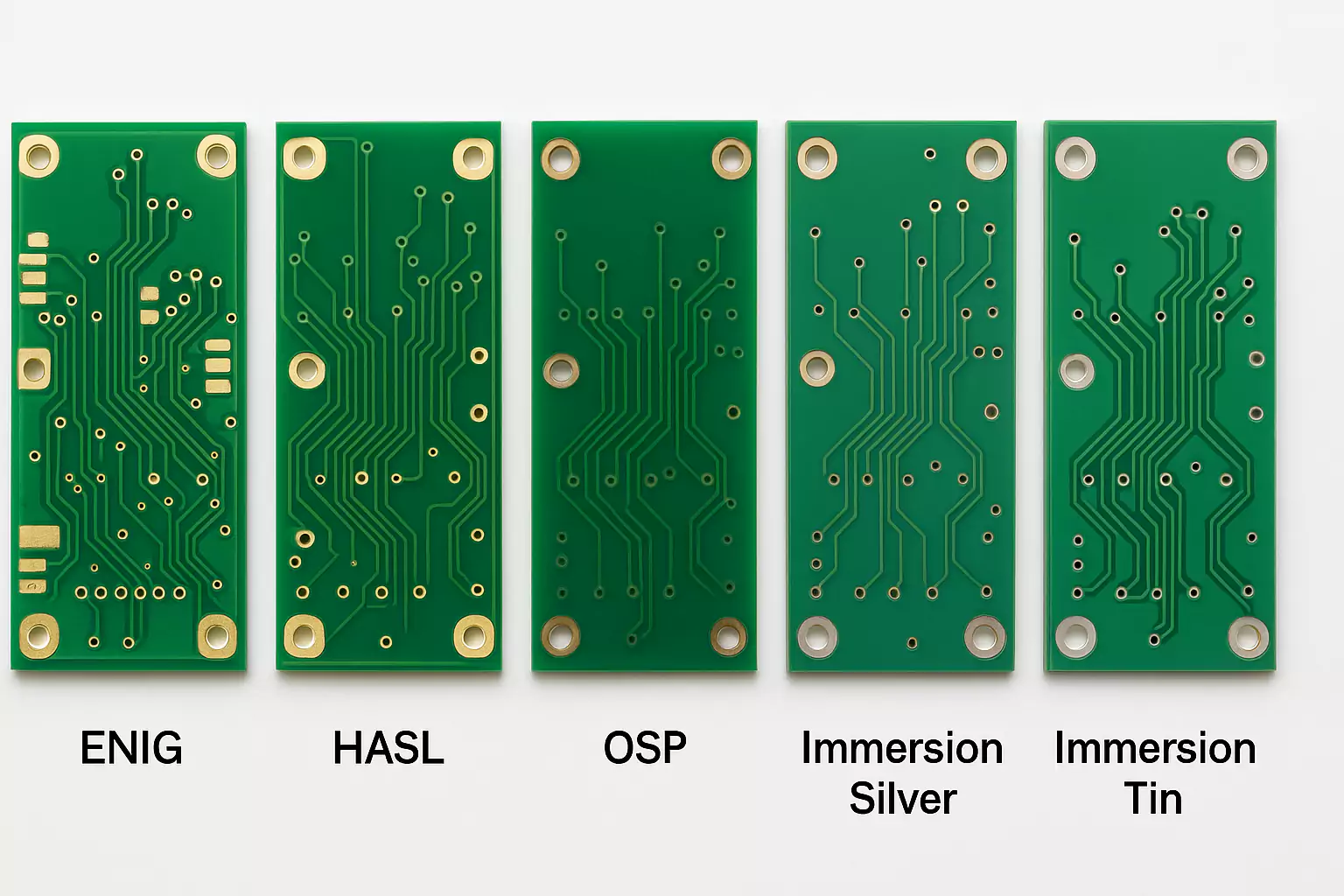

This guide compares the most common PCB surface finishes—Lead-Free HASL, ENIG (Electroless Nickel Immersion Gold), Immersion Silver, Immersion Tin, and OSP (Organic Solderability Preservative)—based on their manufacturing processes, soldering performance, cost implications, and environmental compatibility.

What Is a PCB Surface Finish?

A PCB surface finish is a protective coating applied to exposed copper pads to prevent oxidation and ensure reliable soldering during assembly. Since bare copper oxidizes quickly, a finish is essential to maintain solderability and electrical performance.

Common surface finishes include:

- HASL (Lead-Free Hot Air Solder Leveling)

- ENIG (Electroless Nickel Immersion Gold)

- Immersion Silver

- Immersion Tin

- OSP (Organic Solderability Preservative)

Common PCB Surface Finishing Technologies

1. HASL (Hot Air Solder Leveling – Lead-Free)

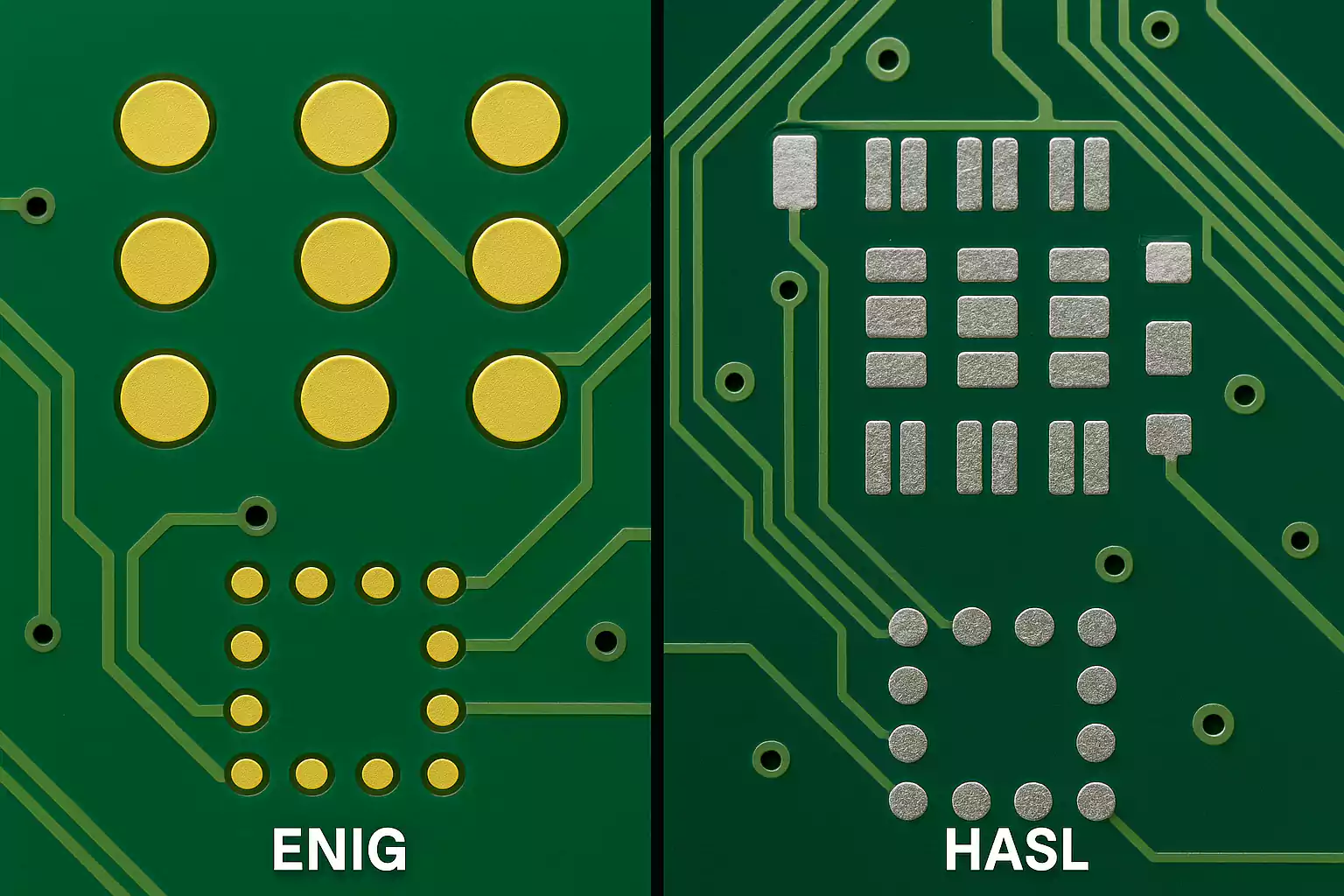

HASL is one of the most traditional and cost-effective PCB surface finishes. In this process, the board is dipped into molten lead-free solder and then leveled using hot air knives to remove excess solder.

It is most suitable for general-purpose, through-hole assemblies and cost-driven PCB designs that do not require fine-pitch components.

Advantages:

- Excellent solderability, especially for through-hole components

- Cost-effective and widely supported by PCB fabricators

- Durable under multiple reflows

Disadvantages:

- Poor surface flatness — not ideal for fine-pitch SMD

- Thermal stress may warp thin boards

- Not suitable for HDI, BGA, or small pad designs

2. ENIG (Electroless Nickel Immersion Gold)

ENIG involves a two-step chemical plating process — a layer of nickel is deposited electrolessly over copper, followed by a thin immersion gold layer. It’s widely used in high-density and high-reliability designs.

It is best used for HDI, BGA-rich, high-reliability products where flatness, durability, and long shelf life are critical.

Advantages:

- Very flat surface — ideal for fine-pitch components and BGA

- Long shelf life and excellent corrosion resistance

- RoHS-compliant and lead-free

- Suitable for ENEPIG and wire bonding with additional steps

Disadvantages:

- Higher cost compared to HASL or OSP

- Risk of “black pad” defect if process is not controlled

- Complex plating process

3. Immersion Silver (ImAg)

This chemical process displaces copper with a thin layer of silver. Immersion silver offers excellent electrical performance and is suitable for high-frequency and fine-pitch applications.

It is ideal for RF, high-speed digital, and signal-sensitive designs that require flat surfaces and good solderability at a moderate cost.

Advantages:

- Excellent solderability and signal integrity

- Flat surface — supports fine-pitch SMD and BGA

- Lower cost than ENIG

- RoHS-compliant

Disadvantages:

- Shorter shelf life; tarnishes easily if improperly stored

- Sensitive to handling, packaging, and storage conditions

- Not ideal for multiple reflows

4. Immersion Tin (ImSn)

Immersion tin deposits a thin, uniform layer of pure tin over copper using a chemical replacement reaction. It is widely used for press-fit or connector-based applications.

This finish is best suited for press-fit connectors and SMT designs in consumer electronics where cost-efficiency and flatness are priorities.

Advantages:

- Good solderability, especially for press-fit and SMT

- Flat surface, compatible with fine-pitch components

- Cost-effective and lead-free

Disadvantages:

- Risk of tin whiskers over time

- Limited shelf life and oxidation sensitivity

- Not suitable for long-term storage or harsh environments

5. OSP (Organic Solderability Preservative)

OSP applies a thin, organic protective layer over bare copper. It preserves the copper’s solderability until the soldering process removes the layer during assembly.

OSP is best for high-volume SMT production environments where boards are assembled soon after fabrication and cost control is essential.

Advantages:

- Extremely flat surface — great for fine-pitch SMT

- Low-cost and environmentally friendly

- Simple application process and RoHS-compliant

Disadvantages:

- Very limited shelf life

- Poor performance in multiple reflow cycles

- Not suitable for through-hole soldering or harsh environments

Surface Finish Performance Comparison

| Surface Finish | Solderability | Surface Flatness | Shelf Life | Cost | Notes |

|---|---|---|---|---|---|

| HASL (Lead-Free) | Good for PTH, less ideal for fine-pitch | Uneven, not ideal for HDI | Medium (~6–12 months) | Low | Economical but not suitable for dense SMT |

| ENIG | Excellent for SMT & BGA | Excellent (very flat) | Long (>12 months) | High | Ideal for HDI and high-reliability builds |

| Immersion Silver | Good, but tarnish-sensitive | Good | Medium (~6 months) | Medium | Good for high-frequency; handle carefully |

| Immersion Tin | Good, risk of tin whiskers | Good | Medium (~6 months) | Medium | Less common due to whisker risk |

| OSP | Excellent for SMT only | Excellent (very flat) | Short (~3–6 months) | Very Low | Best for high-volume, low-cost SMT |

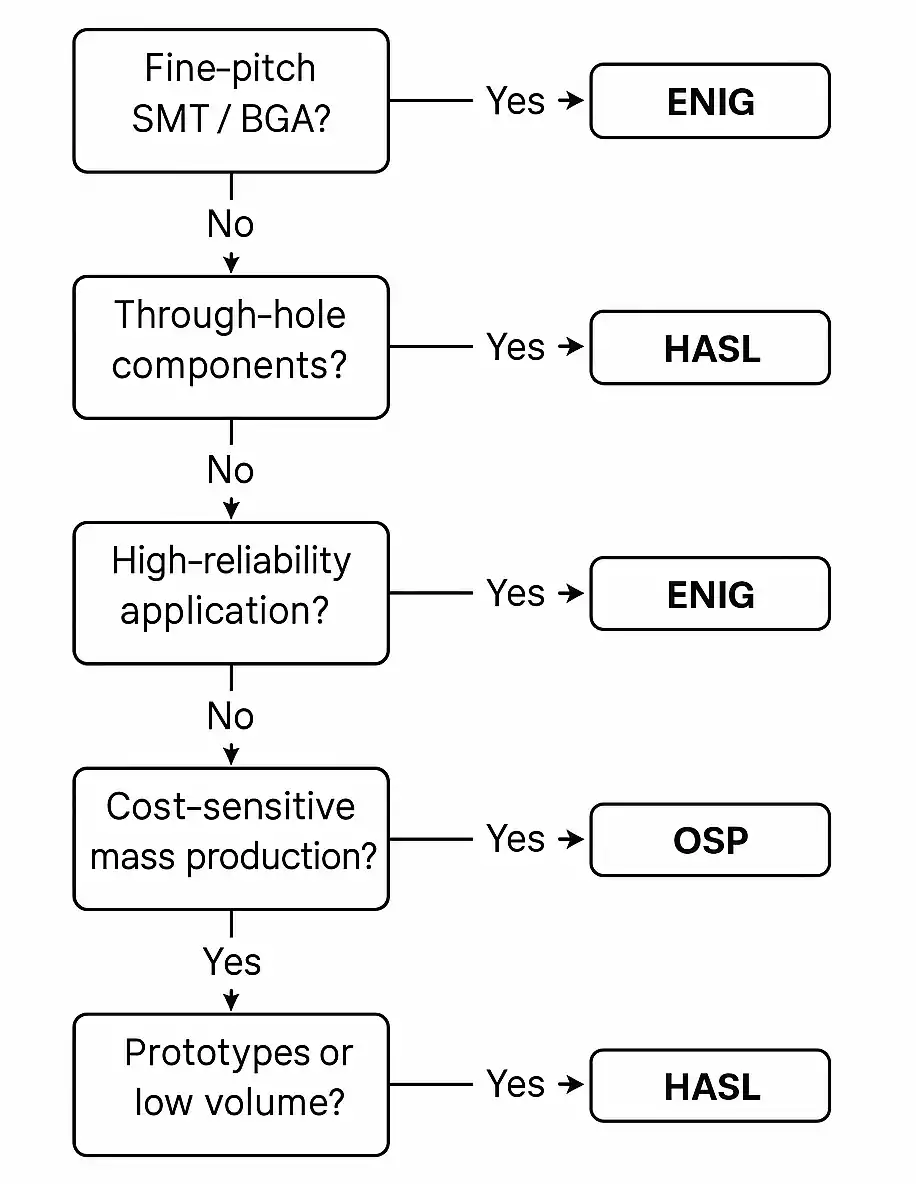

How to Choose the Right Surface Finish

Selecting a PCB surface finish depends on your product’s design, performance needs, and manufacturing conditions. Use the following criteria to guide your decision:

1. Component Type & Pitch

- Fine-pitch SMT / BGA: Use flat finishes like ENIG or OSP.

- Through-hole components: HASL is reliable and robust.

2. Product Requirements

- High-reliability applications (e.g. automotive, medical): Choose ENIG.

- High-frequency designs: Immersion Silver performs well with low signal loss.

- Cost-sensitive mass production: OSP offers low cost with SMT compatibility.

- Prototypes or low volume: HASL is fast and economical.

3. Assembly Process

- Multiple reflows: Prefer ENIG.

- Wave soldering: Avoid OSP unless selectively applied.

- Manual rework needed: HASL or ENIG are safer options.

4. Storage & Handling

- Short lead times: OSP is suitable.

- Long storage or shipping delays: Use ENIG for better shelf life.

Design & Manufacturing Considerations

1. Storage and Shelf-Life Management

Each surface finish has a different tolerance for storage time and environmental exposure:

- OSP and Immersion Silver are highly sensitive to humidity and contamination. They require controlled environments and limited exposure time before assembly.

- ENIG and HASL have better shelf life but can still degrade under improper storage conditions (e.g., high humidity or dust exposure).

- Implement moisture barrier bags (MBB), desiccants, and first-in, first-out (FIFO) inventory control to minimize oxidation risks.

2. Solderability Over Time

Surface finishes degrade over time, especially after multiple thermal cycles or prolonged storage.

- OSP films may wear off with handling or multiple reflows.

- Immersion Tin may develop tin whiskers or intermetallic growth if stored too long.

- HASL and ENIG provide more stable solderability for extended manufacturing or rework windows.

3. Fine-Pitch and High-Density Design Compatibility

Not all finishes are suited for high-density or fine-pitch components:

- ENIG and Immersion Silver offer excellent flatness, making them ideal for BGA, QFN, and 0.5mm-pitch designs.

- HASL (even lead-free) introduces uneven surfaces that may cause bridging or poor contact on fine-pitch pads.

- For HDI boards or tight component placement, always choose finishes with minimal thickness variation and excellent coplanarity.

4. Finish-Specific DFM Recommendations

Certain layout and fabrication guidelines should be adapted based on the chosen finish:

- Immersion Tin: Avoid designs with exposed copper that may encourage tin whiskers. Maintain clean pad definitions to prevent plating issues.

- OSP: Minimize excessive handling or cleaning processes post-finish to preserve the organic coating.

- ENIG: Ensure controlled nickel thickness and avoid aggressive gold removal in rework to reduce black pad risks.

5. Assembly Process Compatibility

Some finishes are more suitable for specific assembly workflows:

- OSP and Immersion Silver perform best with single-pass reflow; multiple reflows can degrade performance.

- ENIG handles multiple reflows and rework more reliably.

- For through-hole components, HASL provides superior hole fill due to its solder coverage.

Conclusion

Each PCB surface finish comes with distinct strengths and limitations. Choosing the right one depends on factors such as component density, assembly method, product lifecycle, and regulatory requirements.

ENIG offers excellent flatness and reliability for high-density designs, while OSP is a cost-effective option for large-volume SMT assemblies. Lead-free HASL, Immersion Silver, and Immersion Tin provide balanced alternatives for various performance and budget needs.

Early integration of surface finish decisions into the design and manufacturing process helps prevent compatibility issues and ensures long-term performance. By aligning finish selection with your product’s specific requirements, you can optimize both quality and cost-efficiency.