When it comes to building electronic products, speed and reliability make all the difference. Designers and startups often face the same challenge — how to turn an idea into a working board without wasting weeks coordinating multiple vendors.

That’s where full turnkey PCB assembly comes in. It’s a one-stop solution that lets you move from design files to assembled boards with a single supplier — saving time, money, and stress.

What Is Full Turnkey PCB Assembly?

A full turnkey PCB assembly means your manufacturer handles every step of the process, from PCB fabrication to component sourcing, assembly, and testing.

You simply provide the required production files:

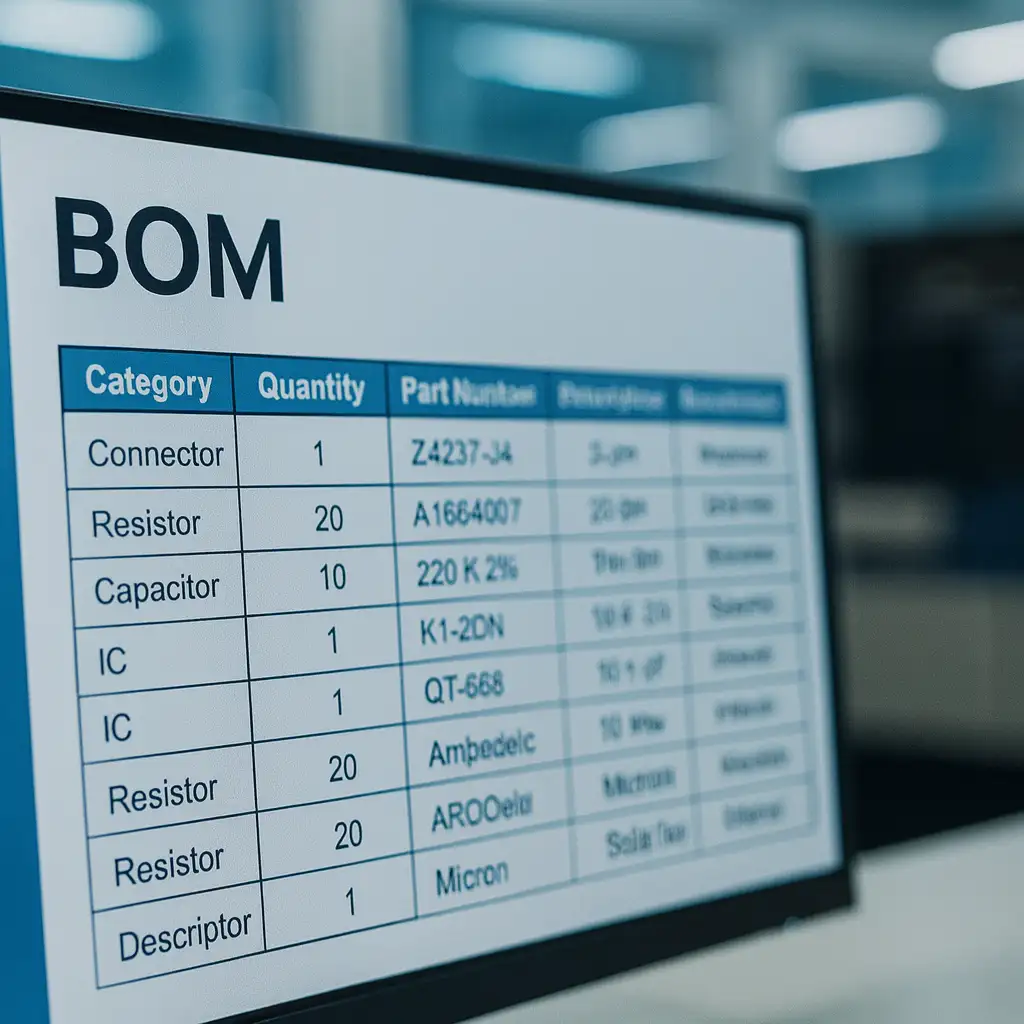

- BOM (Bill of Materials) — with manufacturer part numbers and preferred substitutes.

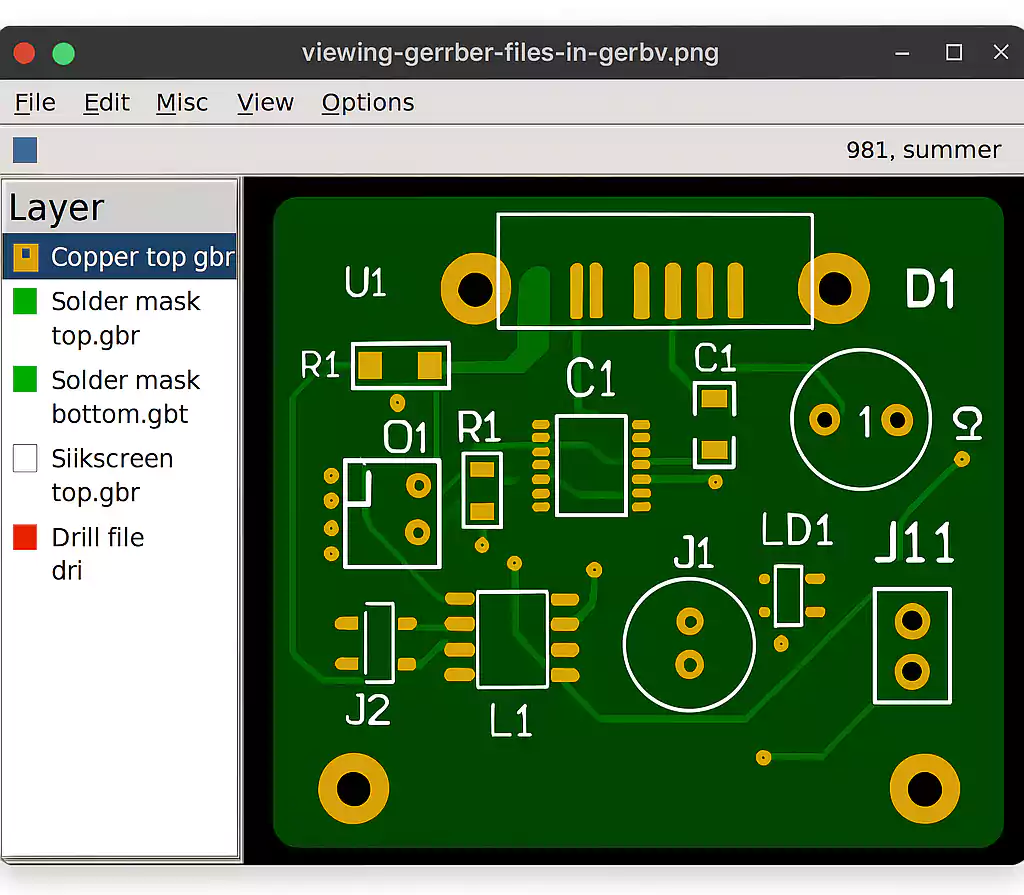

- Gerber or ODB++ files — for PCB layer data.

- CPL (Pick-and-Place or Centroid file) — for component positions and orientations.

- Assembly notes or test instructions, if needed.

In other words, you send the design, and your supplier delivers finished boards that are ready to test or install.

By contrast, a partial turnkey service lets the customer supply some parts while the factory sources the rest, and consigned assembly means the customer provides all materials.

Full turnkey service takes all of that work off your hands — perfect for teams that need to move fast.

Why Choose Full Turnkey PCB Assembly?

1. Faster Delivery

The biggest reason to go turnkey, is speed.

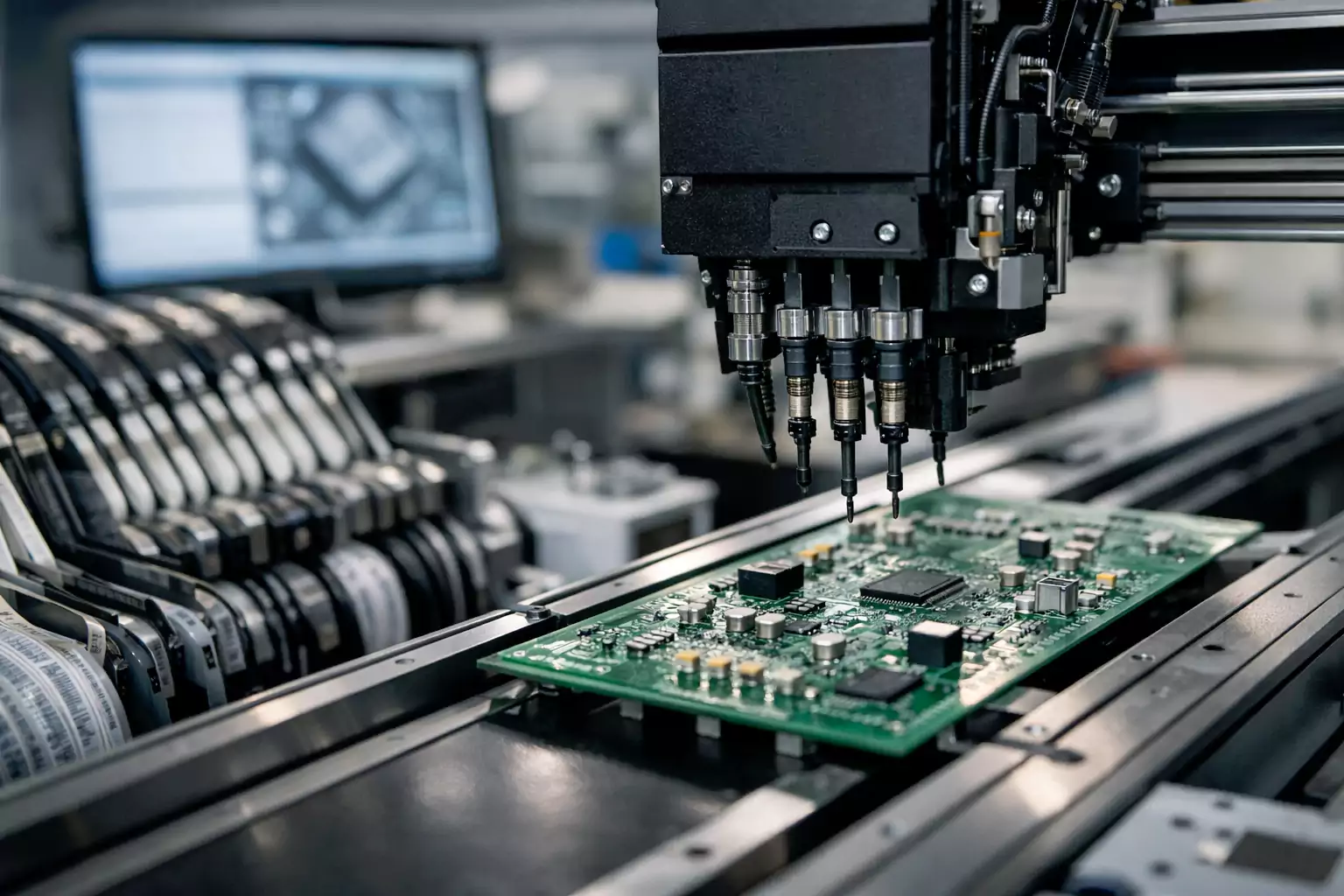

When one vendor manages both manufacturing and component procurement, all steps occur in parallel — rather than waiting for materials to arrive from multiple sources.

This shortens your overall lead time from weeks to days. Many full-turnkey manufacturers, including FastTurnPCB, can deliver quick-turn prototypes in as little as 24–120 hours, depending on material availability and design complexity.

2. Simplified Project Management

Instead of juggling three or four vendors — one for PCBs, one for parts, another for assembly, and possibly one for testing — you work with a single partner.

That means fewer emails, fewer invoices, and fewer chances for errors.

Your supplier becomes the single point of contact responsible for schedules, materials, and final quality.

3. Better Quality and Lower Total Cost

Full turnkey assembly allows early DFM (Design for Manufacturability) and DFA (Design for Assembly) reviews.

Because the same engineering team oversees the whole process, they can spot design or component issues before production starts.

That prevents rework, delays, and unexpected costs later.

When you calculate total project cost — including shipping, coordination, and reassembly — a turnkey build is often cheaper overall than managing multiple suppliers separately.

Full vs Partial vs Consigned: Quick Comparison

| Who buys components | Manufacturer | Shared | Customer |

| PCB fabrication | Included | Included | Included |

| DFM / DFA review | Full | Partial | Limited |

| Lead time | Fastest | Moderate | Slow |

| Responsibility for shortages | Supplier | Shared | Customer |

| Best for | Rapid prototyping, startups, small batch | Companies with existing parts | Strict component control |

If you’re working on a new product, prototype, or short-run production, full turnkey assembly offers the best balance of speed, flexibility, and accountability.

The Full Turnkey Process: Step-by-Step

A reliable turnkey process follows clear stages from quote to shipment. Here’s what it typically looks like:

1. Quote and DFM Review

You upload your files (BOM, Gerber, CPL) and get a fast quote.

Engineering teams review the design for manufacturability, checking for long-lead parts, end-of-life components, and soldering and polarity issues.

This step ensures smooth production and reduces the risk of delays.

2. Component Sourcing and BOM Optimization

The manufacturer purchases parts from authorized distributors such as Digi-Key, Mouser, or Arrow.

If a part is unavailable, they provide equivalent alternatives based on your substitution rules (for example, “must match,” “preferred,” or “OK to replace”).

This flexibility keeps your build on schedule even during component shortages.

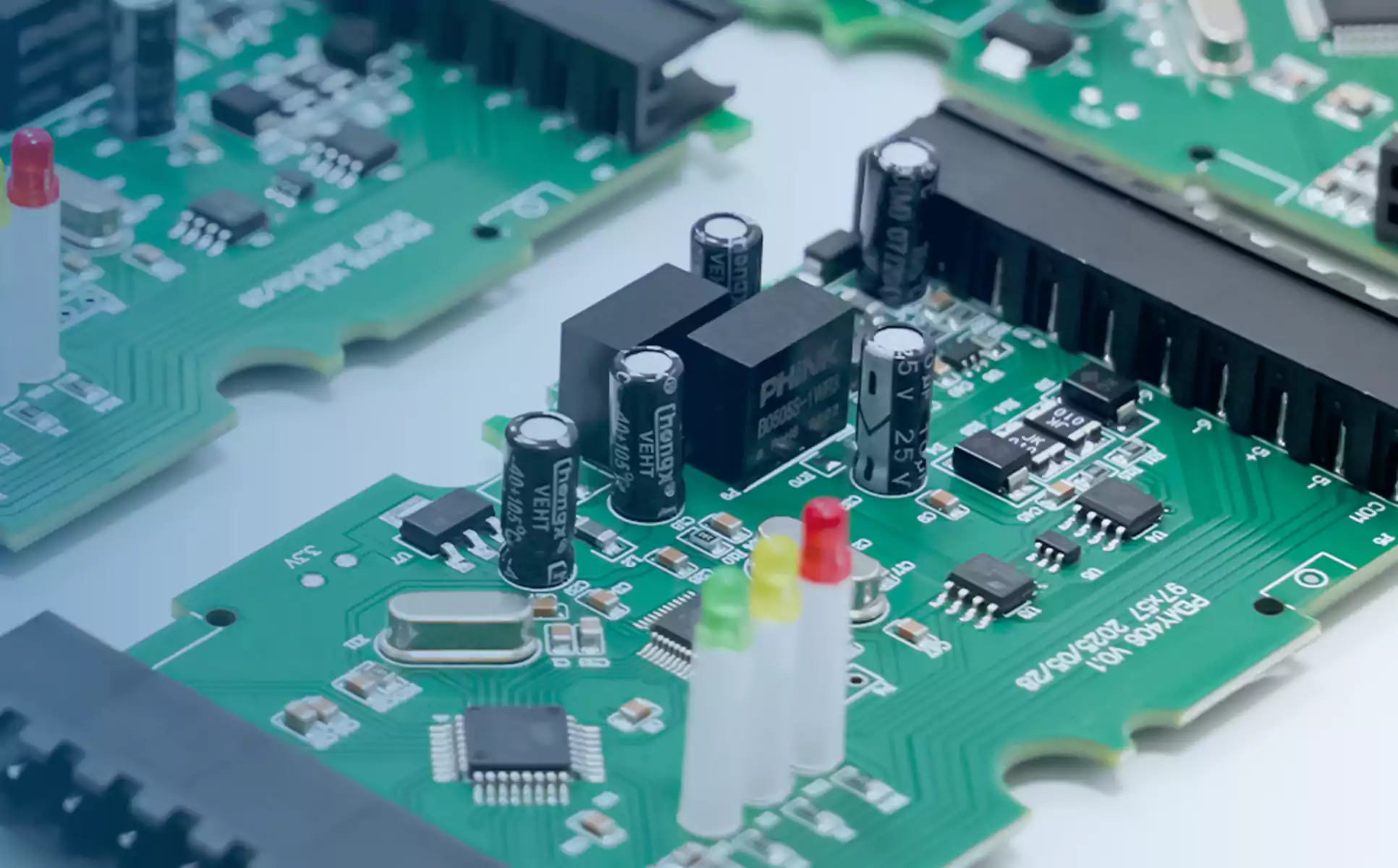

3. PCB Fabrication

The board is fabricated using your specified stack-up, copper thickness, and finish (HASL, ENIG, etc.).

Because fabrication and assembly happen under one roof, the supplier can align panelization, hole tolerances, and fiducials directly with the assembly process.

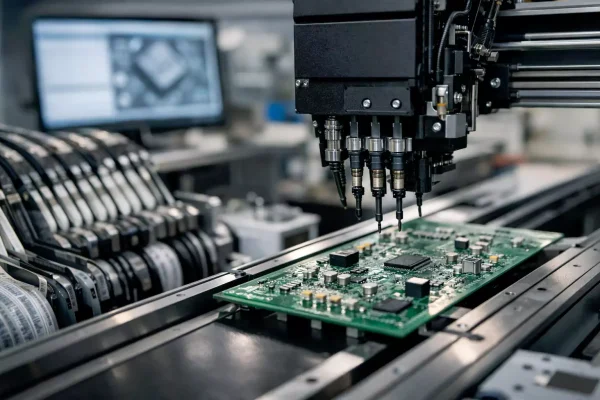

4. Assembly and First Article Inspection

SMT and through-hole components are mounted on the finished boards.

After the first piece is assembled, a First Article Inspection (FAI) verifies correct placement and polarity before moving to mass assembly.

5. Testing and Quality Assurance

Each board is inspected using AOI (Automated Optical Inspection) and, when needed, X-ray for BGAs or hidden joints.

Functional testing or programming can be added according to your instructions.

All test results are documented for traceability.

6. Packaging and Shipping

Once all boards pass inspection, they’re packed in ESD-safe materials and shipped directly to you.

Many suppliers can also handle logistics to drop-ship finished products to your next partner or fulfillment center.

This closed-loop process gives you end-to-end visibility and peace of mind — from design upload to final delivery.

Rapid Prototyping with Full Turnkey Assembly

For hardware startups and R&D engineers, time-to-market is critical.

Full turnkey PCB assembly helps you get working prototypes in hand within 24–120 hours, depending on complexity and part availability.

How it works:

- Pre-stocked materials: Many turnkey shops keep standard laminates and common components on hand for faster turnaround.

- Flexible BOM rules: You can define which parts must not be substituted and which may use equivalents.

- Online DFM feedback: Engineers review your files immediately after upload and suggest quick fixes or replacements.

- Scalable transition: Once your prototype is validated, the same process parameters and tooling can be reused for small-batch production.

That continuity avoids the need to re-qualify new vendors or repeat setup work — saving you time and ensuring consistent quality.

Cost and Lead Time Factors

The total cost and turnaround of your project depend on a few main factors:

- Component availability — If your BOM includes obsolete or long-lead parts, delivery time increases.

- Board complexity — Higher-layer counts, fine-pitch BGAs, or mixed SMT/THT designs may require additional steps.

- Testing requirements — Functional testing, programming, or burn-in adds processing time but improves reliability.

- Surface finish and materials — ENIG or heavy copper boards take longer to process than standard FR-4 with HASL.

- Quantity — Prototype builds (1–20 pcs) are typically faster; larger runs may benefit from combined fabrication and assembly scheduling.

To minimize both cost and lead time:

- Submit a complete BOM with clear alternates.

- Use common packages and available components.

- Provide a CPL (Pick-and-Place list) and clear assembly notes.

- Approve substitutions when possible to prevent shortages.

A good turnkey partner will always confirm changes with you before proceeding.

What You Need to Provide

To get an accurate quote and smooth build, prepare these four files:

- BOM — include manufacturer part numbers, quantity, and substitute preferences.

- Gerber or ODB++ — full PCB layer and drill data.

- CPL / Pick-and-Place File — component positions and rotation.

- Assembly Notes / Test Instructions — any special handling or polarity notes.

With these, your supplier can generate a precise cost and schedule within hours.

How to Choose the Right Turnkey Partner

When evaluating potential suppliers, focus on these six key points:

- Turnaround Speed — Can they support 24–120 hour prototype cycles?

- Procurement Network — Do they source from authorized distributors and manage substitutes?

- Engineering Support — Fast, clear DFM/DFA feedback before production.

- Assembly Capability — Minimum component size, BGA pitch, and inspection systems (AOI/X-ray).

- Transparent Quoting — Clear cost breakdown for materials, assembly, and testing.

- Scalability — Can they handle your next small or medium batch without changing vendors?

A dependable partner combines technical ability with responsive communication and consistent quality.

Common Questions About Turnkey Assembly

1. Should I choose full or partial turnkey?

If you already have an existing parts supply chain or strict sourcing policies, partial turnkey may fit.

If speed and convenience matter most, a full turnkey is better.

2. How fast can I get my boards?

Lead times range from 24 hours for standard prototypes to about 5–7 days for complex builds, depending on material and BOM readiness.

3. What documents do I need?

At minimum: BOM, Gerber, CPL, and assembly notes. The more complete your data, the faster the quote.

4. Can I scale from prototype to small batch easily?

Yes. A full turnkey setup keeps your production parameters and DFM records, so you can reorder without having to repeat the setup.

Conclusion

Full turnkey PCB assembly offers speed, simplicity, and reliability for anyone developing new hardware.

It replaces multiple vendors with one accountable partner who manages everything — from PCB fabrication and sourcing to assembly and testing.

For rapid prototyping and low-volume builds, it’s the fastest path from design to a working product.

FastTurnPCB specializes in advanced PCB manufacturing and full turnkey PCB assembly, offering 1-piece quick-turn prototypes, lead times as fast as 24 hours, and one-on-one engineer support.

Whether you’re testing a new concept or preparing for production, FastTurnPCB helps you bring your ideas to life — faster and smarter.