Introduction

PCB assembly (PCBA) is the process of mounting electronic components onto a bare printed circuit board to create a functional hardware system.

By integrating both surface-mount (SMT) and through-hole (THT) components onto a fabricated board, PCBA transforms raw materials into functional circuits ready for testing, deployment, or enclosure. Whether it's a medical sensor, industrial controller, or IoT device, nearly every modern system depends on the precision and consistency of well-executed PCB assembly processes.

But assembling a board correctly goes far beyond mounting parts. Successful builds require attention to file preparation, component sourcing, paste application, reflow profiles, inspection checkpoints, and cleaning protocols—long before the first board hits production.

This guide breaks down the complete PCBA workflow into practical, engineering-level steps you can apply immediately—covering everything from data prep and component placement to inspection, testing, and delivery.

1. What is PCB Assembly?

PCB assembly (PCBA) is the process of mounting electronic components onto a fabricated bare board to create a functional circuit. It involves soldering components using either surface mount technology (SMT) or through-hole technology (THT).

- SMT places components directly on the surface using automated machines—ideal for compact, high-speed designs.

- THT involves inserting leads through drilled holes—used for stronger mechanical connections.

PCB assembly is distinct from PCB fabrication. While fabrication builds the board, assembly populates it. A well-executed PCBA ensures electrical performance, reliability, and manufacturability.

Here, you’ll learn the step-by-step PCB assembly process and the best practices for selecting components.

Step-by-Step PCB Assembly Process

A well-executed PCB assembly process transforms a bare board into a fully functioning PCBA. Below is a step-by-step breakdown of the standard process used by most contract manufacturers, covering both Surface Mount Technology (SMT) and Through-Hole Technology (THT).

1. Design for Assembly (DFA) Check

Before production begins, the manufacturer reviews the provided Gerber or ODB++ files, Bill of Materials (BOM), and assembly drawings to ensure manufacturability and avoid costly rework.

Key DFA checkpoints include:

- Verifying component footprints and orientations

- Checking solder mask clearances and pad sizes

- Reviewing silkscreen placements to avoid coverage of pads or vias

- Ensuring BOM clarity with part numbers, designators, and descriptions

A clean, well-organized data package enables a smoother transition from design to production.

2. SMT Assembly Using Pick-and-Place Machines

SMT is the most common assembly technique, favored for its speed, accuracy, and support for high-density designs.

a. Solder Paste Application

A stainless steel stencil is aligned with the PCB, and solder paste is applied to exposed pads. Paste deposition consistency is critical for reliable solder joints.

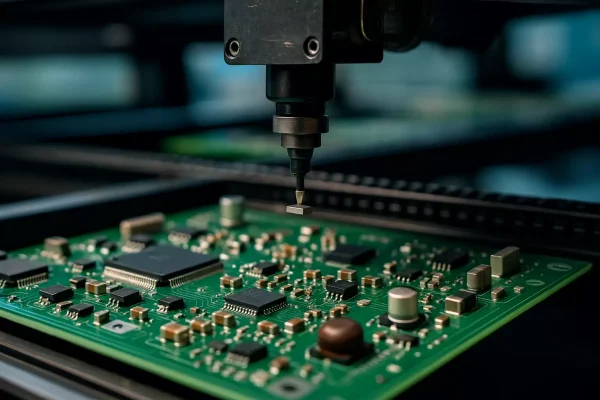

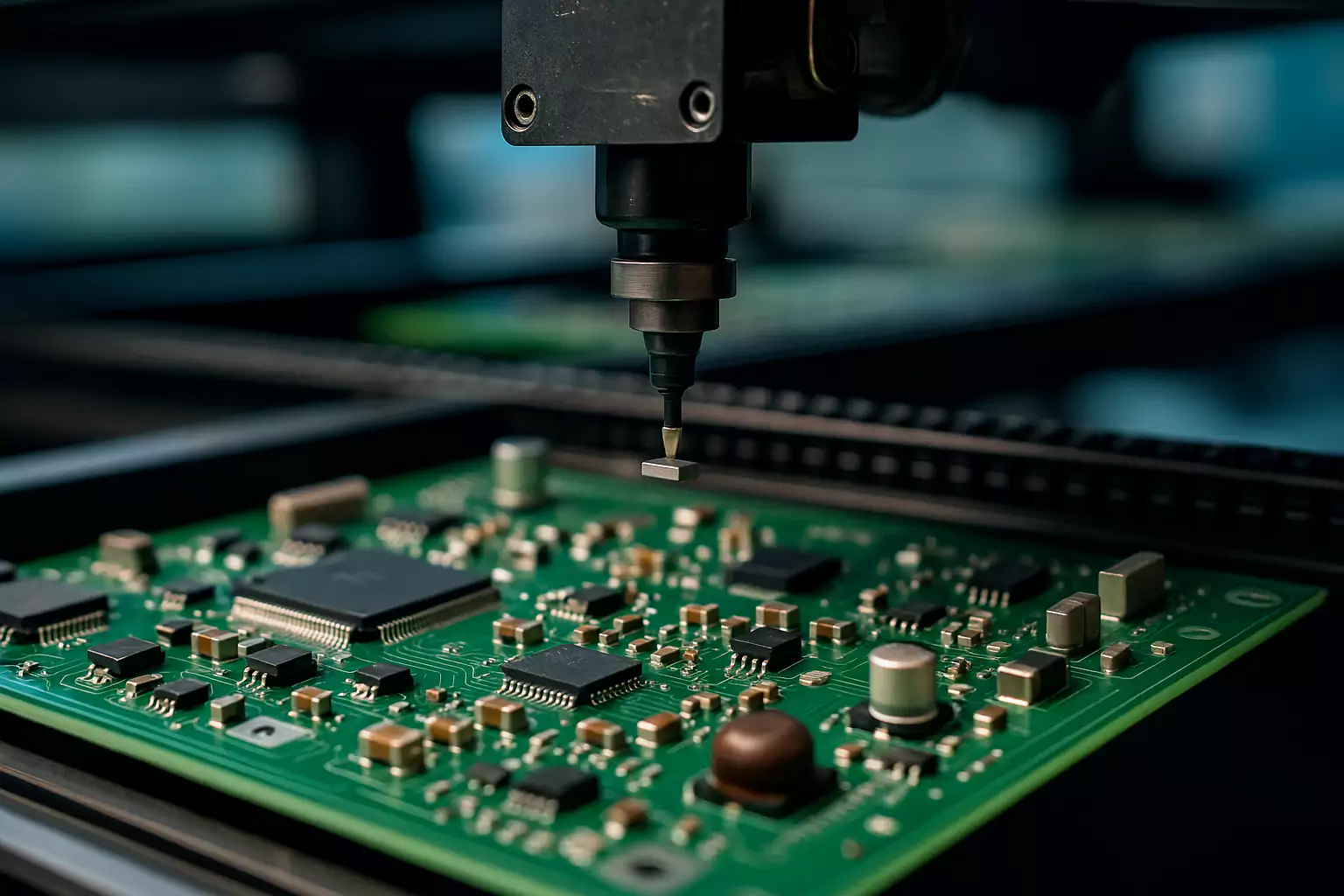

b. Component Placement

Pick-and-place machines accurately position SMT components—such as resistors, capacitors, and ICs—on the board using vacuum nozzles guided by optical systems.

c. Reflow Soldering

The loaded PCB enters a reflow oven where it is gradually heated through several zones. The solder paste melts and solidifies, forming strong metallurgical bonds between the components and PCB pads.

d. Automated Optical Inspection (AOI)

After reflow, the board undergoes AOI, where high-resolution cameras scan for defects like tombstoning, insufficient solder, misalignments, and polarity issues.

e. X-Ray Inspection (for BGA/QFN)

For hidden-joint components such as BGAs and QFNs, X-ray inspection is used to evaluate solder joint integrity beneath the package.

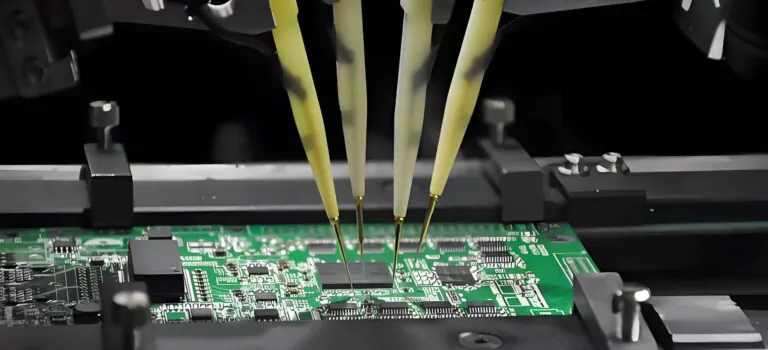

f. Flying Probe Testing (FPT)

FPT is a non-invasive electrical test ideal for low-to-medium volume production. It verifies nets, open circuits, and shorts without requiring a custom test fixture.

3. Through-Hole Assembly

THT assembly is used for connectors, transformers, electrolytic capacitors, and other components that require mechanical strength.

- Components are inserted into drilled holes, either manually or with insertion machines.

- Wave soldering is commonly used for mass soldering of THT parts.

- In cases where selective soldering is required, hand soldering or robotic point soldering may be applied.

THT is often combined with SMT in mixed-technology assemblies, where SMT is typically processed first.

4. Cleaning of Assembled Boards

Depending on the solder flux type, boards may be cleaned to remove ionic residues, which can lead to corrosion or electrical leakage.

- No-clean flux may not require cleaning unless for conformal coating or mission-critical applications.

- Water-soluble flux demands thorough cleaning with deionized water.

5. Soldering of Non-Washable Components

Components sensitive to moisture or high temperatures—such as buzzers, batteries, or some connectors—are manually soldered after cleaning to avoid damage.

This is typically the final soldering stage before inspection and testing.

6. Final Inspection and Testing

At this point, the PCBA is ready for verification.

- Visual inspection ensures cosmetic quality and confirms that no damage occurred during handling.

- In-Circuit Testing (ICT) checks for electrical shorts, open circuits, and proper component values.

- Functional Circuit Testing (FCT) validates that the board performs its intended function under simulated conditions.

7. Conformal Coating (Optional)

If the PCBA will be used in harsh environments (humidity, dust, chemicals), a conformal coating may be applied to protect the board.

Methods include:

- Spray coating (manual or automated)

- Dip coating

- Brush application (for localized protection)

Component Selection Tips for Efficient PCBA

Effective component selection simplifies the assembly process, reduces costs, and improves production yield. Below are four key considerations to ensure a reliable and efficient PCBA build.

1. Source from Trusted Suppliers

Use authorized distributors to avoid counterfeit parts. Ensure traceability and check availability early in the design phase.

2. Use Standard IC Packages

Prefer widely supported packages like QFP (Quad Flat Package)、QFN (Quad Flat No-Lead)、SOIC (Small Outline IC). Avoid exotic or obsolete footprints that may delay assembly or require special handling.

3. Favor SMT over THT

SMT components support automated placement and reflow soldering, making them faster and more cost-effective. Reserve THT for connectors or components requiring mechanical strength.

4. Check Lifecycle and Availability

Avoid EOL (End of Life) and NRND (Not Recommended for New Designs) components. Confirm long-term availability and consider second sources where possible.

Fast Turn PCB Assembly Services

Fast Turn PCB delivers high-quality assembly with fast turnaround. We offer three flexible service models to match your project needs.

Full Turnkey Assembly

We handle everything — component sourcing, assembly, and testing. Ideal for teams seeking a complete, hands-off solution with reliable speed and quality.

Partial Turnkey Assembly

You provide key components, and we source the rest. This hybrid model offers greater control over critical parts while streamlining the remaining process.

Consigned Assembly

You supply all components; we focus solely on assembly. Perfect for customers with established supply chains or specialized sourcing requirements.

Frequently Asked Questions (FAQ)

What is PCB assembly?

PCB assembly (PCBA) is the process of mounting electronic components onto a bare printed circuit board using SMT, THT, or both. It transforms a fabricated board into a functional electronic product.

What documents are needed for PCB assembly?

You’ll need:

•Gerber or ODB++ files

•Bill of Materials (BOM)

•Pick-and-place (Centroid) file

•Assembly drawings and special instructions

What’s the difference between SMT and THT?

•SMT: Surface-mounted components placed directly onto pads and soldered via reflow.

•THT: Leads inserted into holes, soldered via wave or hand soldering.

SMT is better for automation; THT is ideal for mechanical strength.

What are AOI and X-ray inspections used for?

•AOI checks for misalignment, missing parts, and solder defects.

•X-ray is used to inspect hidden joints (e.g., BGAs) for voids or bridging.

Can one board use both SMT and THT components?

Yes. Mixed assembly is common. SMT is usually done first, followed by THT.

Summary

Understanding the full PCB assembly process — from a bare PCB to a fully assembled and tested PCBA — is crucial for ensuring manufacturing efficiency, product reliability, and smooth collaboration with your assembly partner.

This guide has walked you through the critical steps in both SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly processes, including solder paste application, pick-and-place, reflow soldering, wave soldering, inspection methods like AOI and X-ray, and functional testing. We’ve also covered additional processes such as cleaning, soldering of sensitive components, and conformal coating, which play a vital role in product durability and performance.