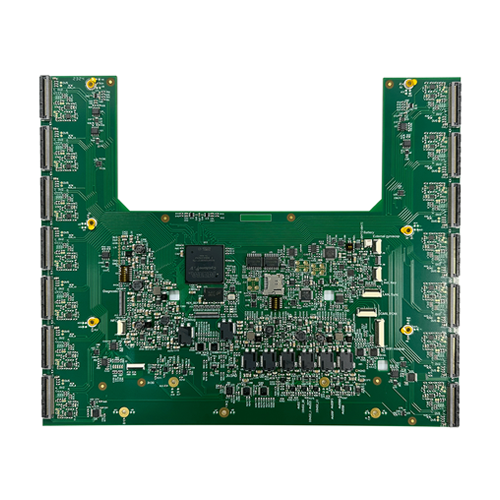

Q1: Why is ARLON PI material used in this Rigid-Flex PCB?

A1: ARLON polyimide materials provide excellent thermal resistance, dimensional stability, and electrical performance — making them ideal for aerospace environments where temperature cycling and reliability are critical.

Q2: What challenges does the 18-layer Rigid-Flex structure pose?

A2: Complex lamination cycles, precision alignment between rigid and flexible zones, and managing warpage are key challenges. Our manufacturing process includes special lamination controls to ensure structural integrity and performance.

Q3: Can impedance values be customized?

A3: Yes, we support custom impedance tuning. Please specify your target impedance and reference layer configuration during the design phase.

Q4: How do you ensure via reliability in aerospace environments?

A4: We follow Class 3A standards with high copper plating thickness (≥30μm) and use strict via-hole integrity testing including thermal shock and cross-section analysis.

Q5: What is the typical lead time for such a complex PCB?

A5: Lead times vary based on design complexity and validation needs. For this 18-layer Rigid-Flex board, the typical production cycle is 20–25 working days, subject to DFM review.