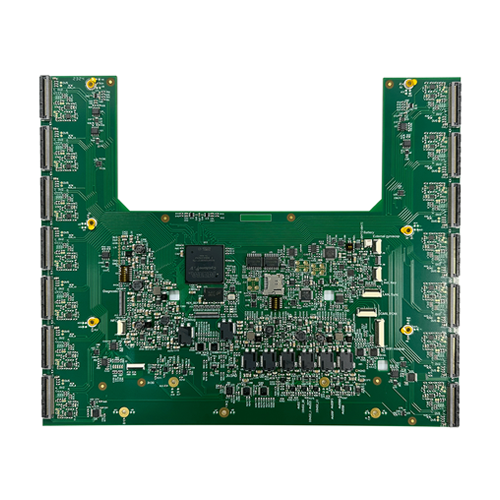

Q1: What makes this motherboard suitable for medical applications?

A1: It is designed and manufactured to meet IEC 60601 requirements, featuring high-precision soldering, medical-grade components, and robust interface support for medical equipment.

Q2: Why use nitrogen reflow soldering with 12 temperature zones?

A2: Nitrogen reflow improves solder joint integrity, reduces oxidation, and provides uniform temperature control—critical for soldering high-density BGA and fine-pitch components.

Q3: Can this board be customized for different medical device applications?

A3: Yes. We offer full customization of layout, interfaces, and component selection to meet specific application needs.

Q4: What inspection methods are used during production?

A4: Each board undergoes Automated Optical Inspection (AOI), X-ray inspection, and functional testing to ensure zero-defect delivery.

Q5: What is the typical lead time for production?

A5: Standard production time ranges from 3–5 weeks depending on design complexity and component availability.