When you’re soldering electronics, plumbing copper pipes, or repairing stained glass, one small chemical can determine whether your solder joints are strong and reliable—or dull, cracked, and weak. That chemical is flux.

So, what is flux in soldering? Flux is a critical material that cleans metal surfaces, prevents oxidation, and helps molten solder flow smoothly to form strong metallic bonds. In short, flux is what makes proper soldering possible.

In this guide, we’ll explain what flux is, what it’s made of, how it works, the different types of soldering flux, and how to choose and use the right flux—especially for PCB and electronics soldering.

Why Flux Matters: The Real Problem Is Oxidation

To understand flux, you first need to understand oxidation.

Metals like copper and tin react with oxygen in the air, forming a thin oxide layer on their surface. This oxide layer is bad news for soldering — solder won’t “wet” it. Instead of spreading and bonding, it beads up, rolls away, or sticks unevenly.

That’s why sometimes solder won’t “stick” to a pad or wire even though it’s hot enough — oxidation is blocking the bond.

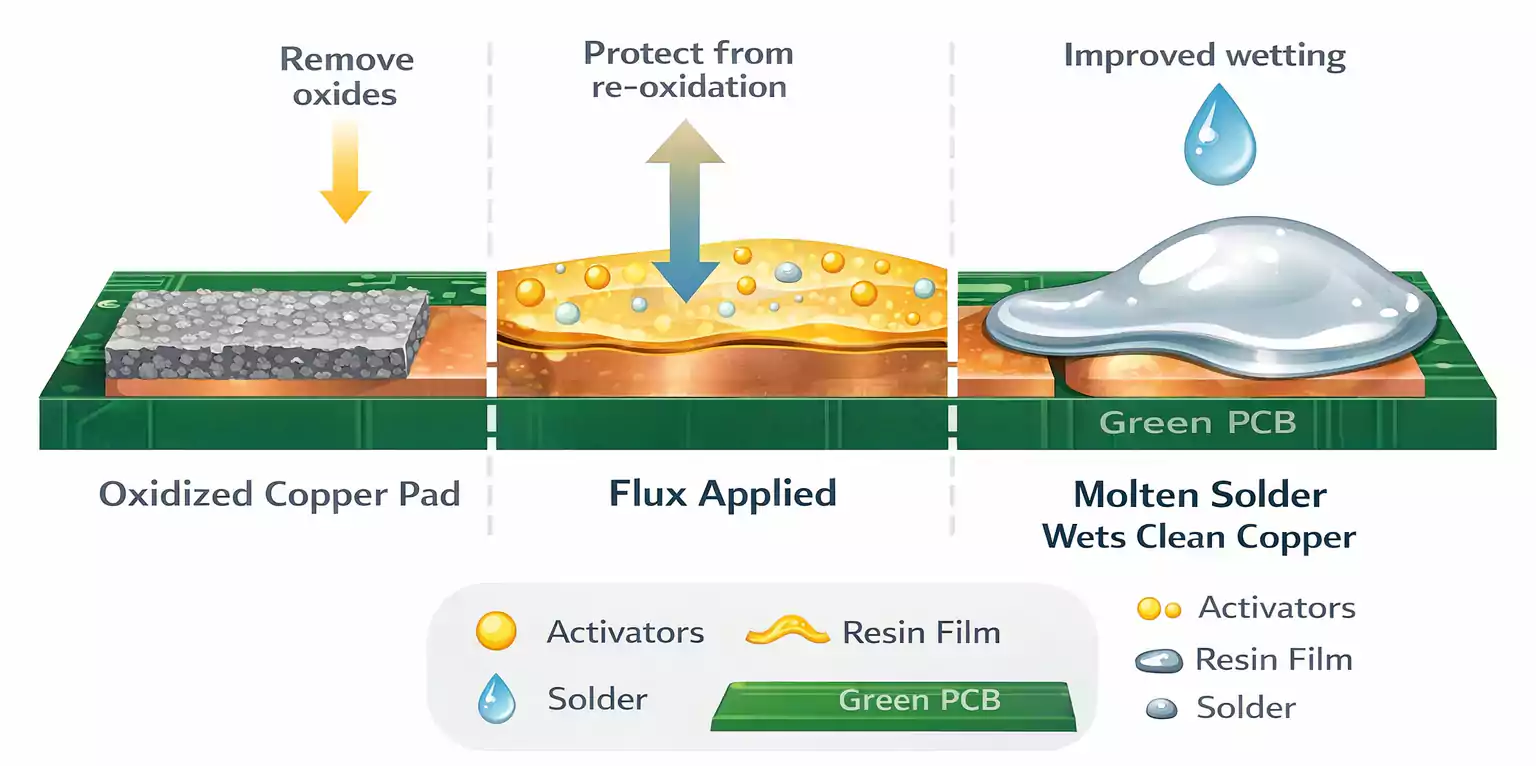

Flux solves three key problems at once

- Removes oxides

- Prevents re-oxidation

- Promotes wetting

Together, these actions ensure that solder properly bonds to both surfaces — giving you that smooth, bright, reliable joint every engineer wants.

What Is Flux Used for in Soldering?

People often ask: “Do I really need to use flux?” The short answer is yes — in most cases.

Even though many solder wires have a built-in flux core, additional flux is often required, especially for repair or precision work.

When you must (or should) add flux

- Rework and repairs.

- Fine-pitch or drag soldering.

- Hot-air or reflow work.

- Tinning wires or plated surfaces.

When the flux in the solder wire might be enough

- New, clean PCBs with good solderability and a controlled process (e.g., automated reflow).

- Hobby projects or quick joints where the surfaces are fresh, and the solder flows easily.

Still, even experienced technicians apply a small amount of external flux — it improves consistency, reduces rework, and extends tip life.

What Is in Soldering Flux?

Flux is not just one chemical — it’s a formulated blend of several components that work together. While the exact recipe varies by manufacturer and type, nearly all soldering fluxes include three key elements:

1. Activators (acids or halides)

These are the “cleaning agents” that dissolve oxides and expose bare metal. They’re usually mild organic acids or halide salts. Stronger activators mean faster cleaning — but also higher corrosion risk if residues remain.

2. Solids or resins

Resins (like rosin from pine trees) act as carriers and protective films. They encapsulate the clean metal and prevent re-oxidation as the joint cools. They also influence how sticky, tacky, or glossy the flux feels.

3. Solvents or carriers

Solvents determine the flux’s form: liquid, paste, or pen. They evaporate when heated, leaving only the active ingredients at the joint.

Some formulations add wetting agents or rheology modifiers to control flow, and stabilizers to improve shelf life.

Types of Flux for Electronics Soldering

Fluxes are often categorized by their residue behavior and cleaning requirement, rather than their chemical makeup. The three major families you’ll encounter are:

1. Rosin-based flux (R, RMA, RA)

- Made from natural rosin resin with mild to medium activators.

- R (Rosin): least active, leaves hard, glassy residue.

- RMA (Rosin Mildly Activated): the most common for hand soldering.

- RA (Rosin Activated): high activity, excellent cleaning power, but must be cleaned afterward.

- Works well for through-hole and manual soldering.

2. No-clean flux

- Formulated with very mild activators that leave non-conductive, non-corrosive residues.

- Designed for processes where post-cleaning is impractical (like mass SMT production).

- “No-clean” doesn’t always mean “never clean.” In high-impedance or conformal-coated circuits, residue can still cause problems.

3. Water-soluble (organic acid) flux

- Uses organic acids that are highly active and easily cleaned with water.

- Excellent for difficult-to-solder surfaces or lead-free alloys.

- Must be washed after soldering — residues are corrosive and hygroscopic.

| Rosin (R/RMA/RA) | Low–High | Hard, amber film | Optional → Required | Hand soldering, general PCB |

| No-clean | Low | Thin, clear residue | Usually not | Mass SMT production |

| Water-soluble | High | Water-soluble residue | Always | Lead-free, high-temp, reflow |

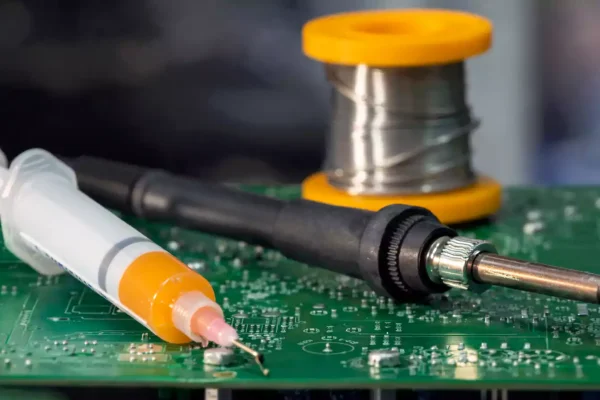

Flux Forms: Liquid, Gel, Paste, Pen, and Flux-Core Wire

Flux doesn’t come in just one shape or texture — each form suits a different task.

- Liquid flux: Low viscosity, ideal for pre-coating or dipping PCBs before wave soldering. Easy to over-apply, so use sparingly.

- Gel or tacky flux: Thick and sticky. Perfect for rework, drag soldering, or hot-air repairs — it stays where you put it.

- Flux pens: Convenient for precision touch-ups and field repairs. They deliver a metered amount without mess.

- Flux-core solder wire: The most common form for hand soldering. The hollow core contains rosin-based flux that activates as the solder melts.

- Solder paste: A blend of powdered solder alloy and flux; used for SMT stencil printing and reflow.

Each format serves a specific workflow — the key is matching flux form to your process.

Should You Clean Flux Residue?

Flux residue is the silent factor that determines long-term reliability in electronics manufacturing.

When cleaning is recommended

Even with “no-clean” formulas, cleaning can prevent future headaches:

- Circuits with high impedance or high voltage nodes.

- Boards that will be conformal-coated or potted — residue can prevent adhesion.

- Assemblies requiring in-circuit testing (ICT) — sticky residues, trap dust, or hinder probe contact.

- Environments with humidity, condensation, or ionic contamination.

How to clean

- Rosin or no-clean flux: Use isopropyl alcohol (IPA) or dedicated solvent cleaners with a soft brush or lint-free wipe.

- Water-soluble flux: Rinse with deionized water, sometimes with mild detergent, then dry thoroughly.

- Never mix solvents or use aggressive acids — they may damage solder mask or components.

A general rule: if you see residue, or if reliability matters, clean it.

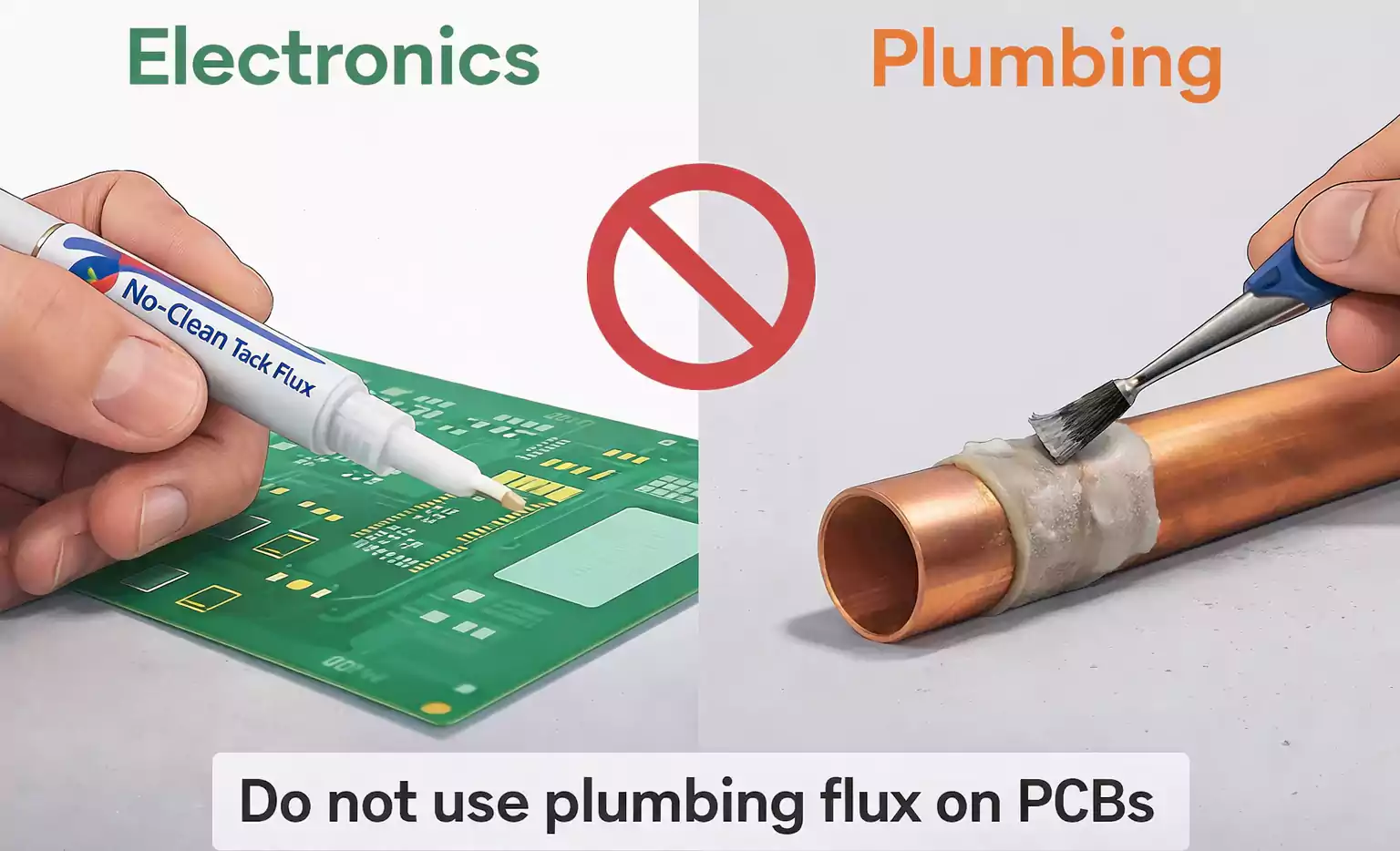

Electronics Flux vs Plumbing Flux

Here’s where many beginners go wrong.

Flux for plumbing or metalwork is not the same as flux for electronics.

- Plumbing flux (used for copper pipes) contains stronger acids, such as zinc chloride or ammonium chloride. It’s designed to clean large, rough surfaces at high temperatures.

- In electronics, those same acids are disastrous — they corrode copper traces, eat solder mask, and create conductive paths that cause shorts or leakage.

If you accidentally used plumbing flux on a PCB, immediately wash with warm water and alcohol, and inspect for corrosion. But ideally, keep plumbing flux far away from electronics workbenches.

How to Use Flux Correctly

Using flux isn’t complicated, but there’s a right way to apply it for best results:

- Pre-clean the surface. Remove oils, fingerprints, or heavy oxidation with IPA or a fine abrasive.

- Apply a thin, even layer. Too much flux can spatter or leave sticky residue.

- Heat the joint gradually. Flux activates between 300 and 400 °F (150–200 °C). Let it sizzle and clean before feeding solder.

- Feed solder into the joint. Once the flux has done its job, the solder should flow freely and cover the pad.

- Remove heat and inspect. Good joints are smooth, shiny, and concave.

- Clean if necessary. See the previous section for cleaning tips.

Common mistakes to avoid

- Using too much flux: Leads to residue, smoke, and potential corrosion.

- Under-heating: Flux never activates fully; solder won’t bond.

- Over-heating: Burns the flux, leaving blackened residue and poor wetting.

- Mixing flux types: Different chemistries can react unpredictably.

Troubleshooting: Fix These Soldering Problems with the Right Flux

| Solder won’t stick / beads up | Oxidized surface, no flux | Apply fresh flux and clean surface |

| Dull, grainy joint | Burned or spent flux | Reduce heat, re-flux, and re-solder |

| Solder bridges / shorts | Too much flux or improper type | Use gel flux sparingly; clean residue |

| Black or sticky residue | Overheating or acid flux | Clean thoroughly, switch to rosin/no-clean |

| Reworked joint keeps failing | Residue buildup | Fully clean before adding new flux |

Flux isn’t magic, but it’s the single most effective way to correct 80% of common soldering issues.

FAQ

Can you solder without flux?

Technically, yes — but soldering becomes unpredictable. Without flux, oxidation prevents wetting, leading to weak or intermittent joints.

What is in soldering flux?

Flux contains activators (acids or halides), resins, solvents, and sometimes additives to control wetting and viscosity.

What is flux used for in soldering?

Flux cleans and protects metal surfaces so solder can bond properly, producing strong, conductive joints.

Is solder paste the same as flux?

No. Solder paste is a mixture of fine solder alloy powder and flux. The flux activates during reflow, while the alloy forms the joint.

Is no-clean flux really “no clean”?

Only under controlled conditions. In sensitive or high-impedance circuits, even “no-clean” residue may require removal.

Can I use plumbing flux on electronics?

Never. Plumbing flux is acidic and will corrode PCB copper and components.

How do you clean flux residue from a PCB?

Use isopropyl alcohol or a specialized solvent and a lint-free brush for rosin or no-clean types; rinse water-soluble flux with deionized water.

What type of flux is best for PCB rework?

Tacky or gel-type no-clean or RMA flux works best — it stays put and provides long activation.

Final Thoughts

Flux may seem like a minor detail, but it's the foundation of every strong, reliable solder joint.

Understanding how flux works—and choosing the right type—can significantly improve yield, reduce rework, and extend the lifespan of your products.

For best results, always use electronics-grade flux, follow proper cleaning and handling protocols, and ensure it's compatible with your solder alloy and manufacturing process.

At FastTurnPCB, we specialize in high-quality PCB fabrication and assembly that meets strict IPC standards. Our processes are built to ensure every solder joint on your board is as clean, consistent, and dependable as the flux that made it possible.