In modern electronics design, protecting power rails from overcurrent, short circuits, or reverse connections is more important than ever. Traditional glass fuses and PTC resettable fuses (Polyfuse) are still standard, but as systems demand faster response, better precision, and automatic recovery, the eFuse — or electronic fuse IC — has become the more intelligent choice.

This guide explains what an eFuse is, how it works, how it compares to conventional fuses, and how to choose the right one for your PCB design.

What is an eFuse?

An eFuse (short for electronic fuse) is a semiconductor-based power protection device that replaces a traditional fuse with a fully integrated circuit.

It uses a MOSFET as the switching element, continuously monitors voltage and current, and instantly limits or cuts off the power when a fault occurs. Once the fault clears, the eFuse can automatically or manually reset — no physical replacement required.

In other words, while a conventional fuse physically melts when overloaded, an eFuse thinks before it reacts — measuring, controlling, and recovering intelligently.

Why Use an eFuse? The Problems It Solves

Every power rail faces a few common threats:

- Overcurrent or short circuits caused by cable faults, connector damage, or load failure

- Inrush current when charging large capacitors during startup

- Overvoltage due to transient spikes, power-supply overshoot, or plug-in surges

- Reverse current or reverse polarity when the load or power source is misconnected.

An eFuse can protect against all of these with precise control and fast reaction — often in microseconds, far faster than any mechanical or thermal device.

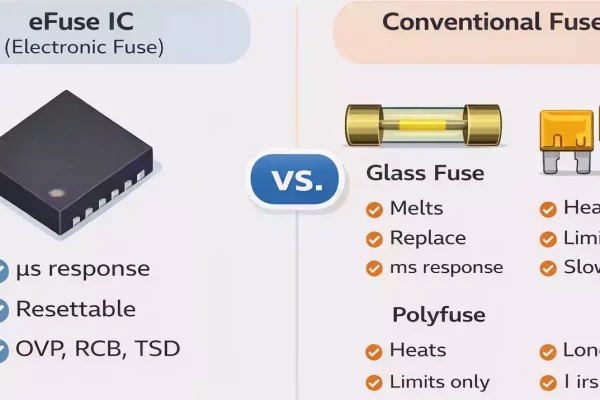

eFuse vs. Glass Fuse vs. Polyfuse (PTC)

One of the most common questions engineers ask is: “How is an eFuse different from a fuse or a PTC?”

Let’s break it down.

1. How They Work

| Glass Fuse | Metal wire melts from excessive heat | Slow (milliseconds) | Must be replaced |

| Polyfuse / PTC | Polymer material heats up and increases resistance | Moderate | Auto reset after cooling |

| eFuse IC | Measures current/voltage, drives a MOSFET to limit or cut off | Very fast (µs range) | Auto or controlled reset |

Traditional fuses depend on heat buildup. eFuses rely on active electronic sensing — making them far more precise and consistent.

2. Response and Recovery

- Glass fuse: Once blown, it’s gone.

- PTC fuse: Can reset after cooling, but recovery time is slow, and behavior is nonlinear.

- eFuse: Can auto-retry after a fault, or latch off until an enable signal resets it — giving designers complete control.

3. Auto-Retry vs. Latch Mode

Most eFuses support two operating modes:

- Auto-retry mode: The device automatically re-enables power after a short period of inactivity. Useful for consumer or portable systems that must recover without user intervention.

- Latch-off mode: The eFuse remains off until a controller or MCU toggles the enable pin — preferred in safety-critical or industrial systems.

How an eFuse Works

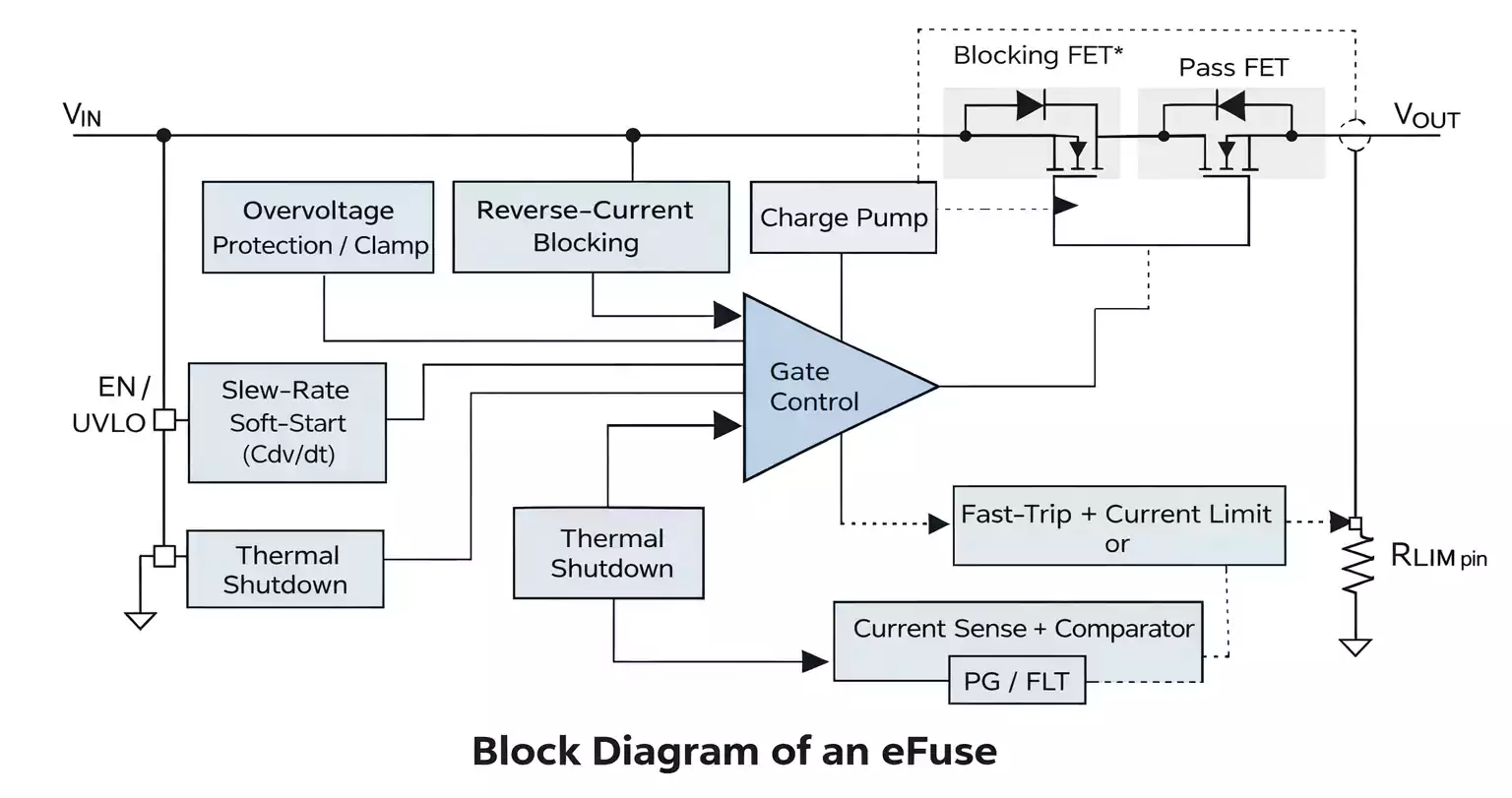

An eFuse integrates several blocks that work together to monitor and protect the power path.

Internal Structure

- MOSFET Switch: Carries the load current and disconnects power during a fault.

- Current Sense Circuit: Measures voltage drop across a shunt resistor or internal sense FET.

- Comparator/Control Logic: Detects whether the current or voltage exceeds the programmed limits.

- Gate Driver: Quickly turns the MOSFET on or off to limit current or shut down.

- Protection Features: OCP (overcurrent), OVP (overvoltage), reverse blocking, and thermal shutdown.

When the sensed current exceeds the threshold, the device enters current-limit mode — clamping the current at a fixed level — or switch-off mode, disconnecting the load entirely. The choice depends on device configuration.

Programmable Current Limit

Most eFuse ICs let designers set the current limit with a simple external resistor (RILIM).

This makes the eFuse family flexible for many current ratings — from sub-amp USB rails to multi-amp power distribution lines.

Built-In Protection Functions

One reason eFuses are so popular is that they combine multiple protection mechanisms into a single small chip. The most common include:

- OCP (Over-Current Protection): Limits or cuts off the load current when it exceeds a set threshold.

- SCP (Short-Circuit Protection): Detects severe faults and instantly shuts off to prevent board damage.

- OVP (Over-Voltage Protection): Clamps or disconnects the output if the input voltage spikes.

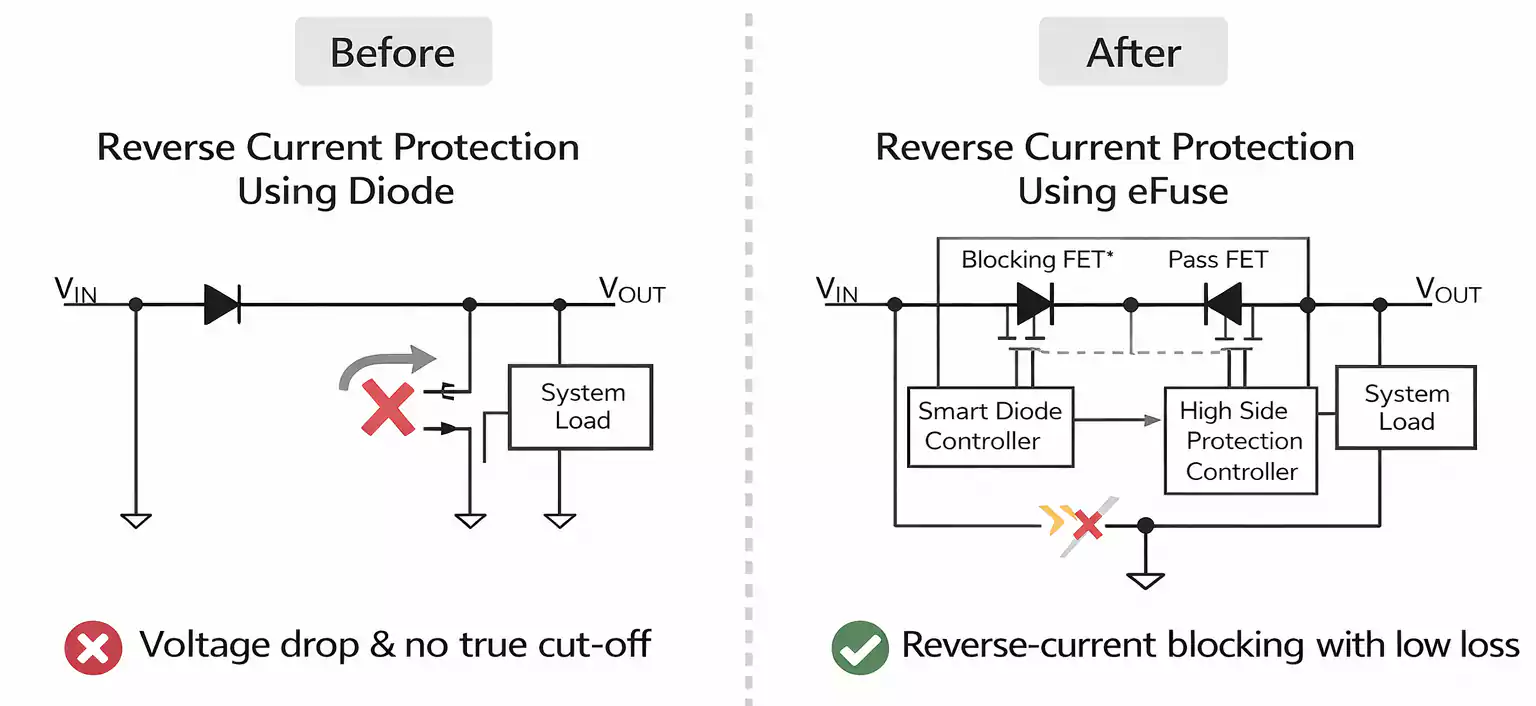

- RCB (Reverse-Current Blocking): Prevents current from flowing backward when power sources are paralleled or hot-swapped.

- TSD (Thermal Shutdown): Turns off the FET if the die temperature exceeds the safe limit.

- Inrush / Slew-Rate Control: Soft-starts the load to avoid voltage dips or connector arcing during plug-in.

- Reverse Polarity Protection: In some devices, the MOSFET orientation blocks reverse input connection.

Essentially, an eFuse does the job of several discrete components — a fuse, TVS diode, MOSFET switch, and protection controller — in a single IC.

Advantages Over Conventional Fuses

- Speed and precision: Detects overcurrent electronically within microseconds instead of relying on thermal delay.

- Resettable and maintenance-free: No need to replace a blown fuse — recover automatically or by software command.

- Integration and space-saving: Combines multiple protection functions into a single chip, reducing PCB area and BOM cost.

- Consistent behavior: Protection thresholds remain stable over temperature and aging, unlike polymer fuses.

- System intelligence: Status pins or I²C telemetry enable real-time fault monitoring and diagnostics.

For high-reliability or densely packed boards, those advantages are hard to ignore.

How to Choose the Right eFuse

When selecting an eFuse IC, consider these parameters:

- Input voltage range (VIN): Match the maximum and transient voltage of your system (e.g., 5 V USB, 12 V, or 24 V industrial).

- Continuous and peak current: Choose an eFuse rated slightly above your maximum load but below the safe limit of the wiring or connector.

- Current-limit accuracy and type: Some parts use a fixed ILIM; others are programmable with ±10% or better accuracy.

- RDS(on) and power loss: Lower resistance means less heat and voltage drop.

- Protection features needed: OVP, RCB, inrush control, thermal shutdown — pick only what your system requires.

- Fault recovery behavior: Decide between auto-retry and latch-off based on safety needs.

- Diagnostics: Look for status outputs such as Power Good (PG) or Fault (FLT) pins to simplify system monitoring.

By evaluating these factors, you can balance protection level, response time, and efficiency for your design.

Typical Applications

1. USB and Type-C Ports

USB power delivery requires fast and repeatable protection.

eFuses protect VBUS from short circuits, overvoltage, or back-drive conditions during hot-plug events — something no glass fuse can do reliably.

2. Consumer and Computing Devices

Laptops, SSDs, printers, game consoles, VR headsets, and smart speakers all use eFuses to guard internal DC rails.

They allow automatic recovery after transient faults, reducing service costs and downtime.

3. Industrial Power Distribution

In 12 V or 24 V industrial systems, eFuses provide resettable branch protection with diagnostic feedback — replacing bulky relays or manual breakers.

4. Automotive and EV Power Systems

High-voltage eFuses are emerging for EV battery and inverter protection.

Unlike thermal fuses that react in milliseconds, semiconductor fuses can disconnect a faulted path in microseconds — fast enough to protect SiC or GaN power devices.

5. Servers and Storage Equipment

In data centers, eFuses prevent backfeed between redundant power supplies and enable precise fault isolation for hot-swappable blades and drives.

PCB Design Tips

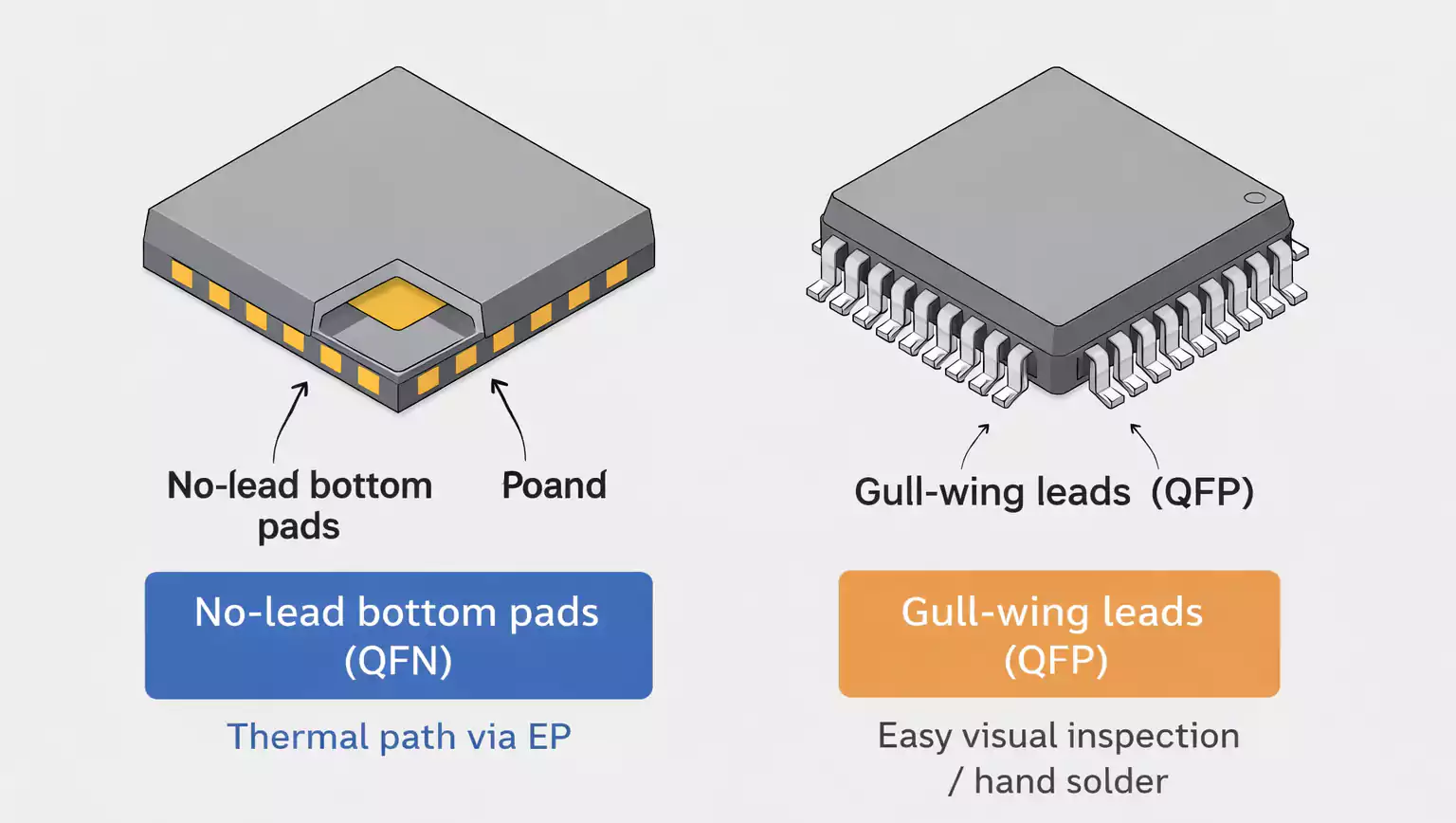

Even though an eFuse integrates most protection logic, proper PCB layout still matters.

Placement: Keep the input and output traces short and wide. Place input/output capacitors close to the device pins to minimize inductive spikes.

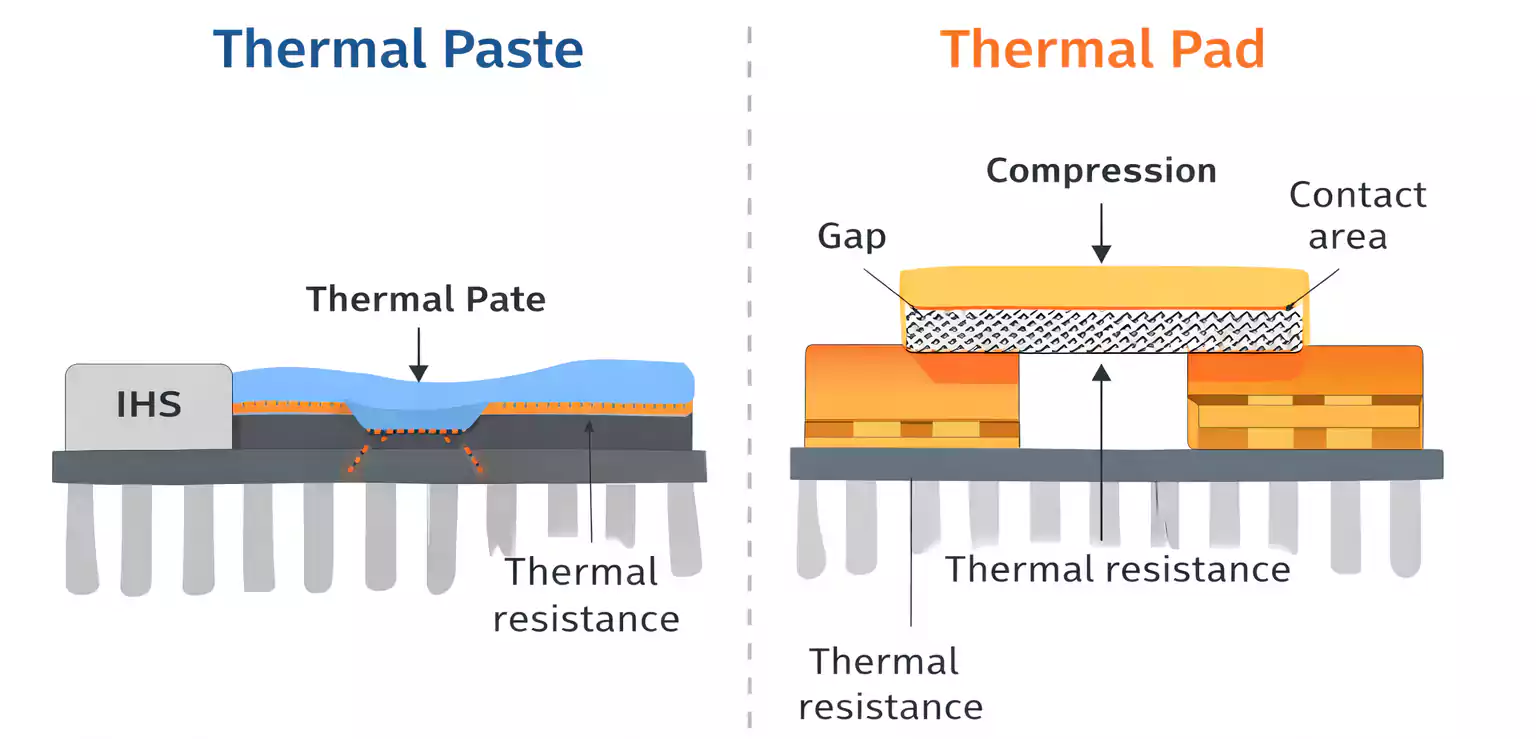

Thermal design: Use copper planes or thermal vias under the package to spread heat from the FET.

Signal routing: Keep sense and control pins away from noisy power traces. Use Kelvin sensing if available.

FAQ

Why does the eFuse trip at startup?

Because the load capacitor causes a large inrush current, increase the soft-start capacitor or current-limit threshold.

Why does it repeatedly restart (“hiccup” behavior)?

In auto-retry mode, if the fault remains, the device cycles between on and off. Switch to latch-off mode if continuous retries are undesirable.

Can an eFuse completely replace a traditional fuse?

In most low-voltage electronic systems, yes.

However, for specific safety certifications (e.g., UL/IEC for mains protection), a physical fuse may still be required in series.

Why not just use a Polyfuse?

PTCs limit current but still allow significant voltage and heat buildup during faults. eFuses provide true disconnection and repeatable response time.

The Other Kind of eFuse (On-Chip OTP Fuses)

The term “eFuse” can also refer to tiny fuses fabricated within ICs.

These on-chip eFuses are one-time programmable links that permanently open when a small current pulse melts them.

They store calibration data, turn hardware features on or off, and lock cryptographic keys for secure boot or device ID.

Although both share the “fuse” concept, they serve different purposes:

| Location | On PCB, in power path | Inside SoC or MCU silicon |

| Purpose | Protect circuits from faults | Store configuration / security bits |

| Reusable | Yes (resettable) | No (one-time programmable) |

Conclusion: When to Choose an eFuse

Choose an eFuse when your design requires:

- Fast, precise protection for sensitive loads

- Automatic recovery without manual fuse replacement

- Compact integration of overcurrent, overvoltage, and reverse blocking

- Diagnostic feedback and intelligent system control

For low-cost, disposable products, a simple fuse may still be OK.

But for high-reliability, compact, or service-free designs, eFuses deliver a modern, intelligent layer of power protection that mechanical fuses can’t match.