Copper Clad Laminate (CCL) is a core material in electronics manufacturing. Whether designing your first prototype PCB or researching materials for mass production, understanding CCL—its structure, types, performance traits, and cost factors—is essential.

What Is Copper Clad Laminate (CCL)?

At its core, Copper Clad Laminate (CCL) is a composite sheet material made by laminating thin layers of copper foil bonded onto a non-conductive substrate such as fiberglass, resin, paper, or specialty polymers. It serves as the base material for printed circuit boards (PCBs).

During PCB fabrication, the unwanted copper is etched away, leaving conductive traces and planes that interconnect electronic components. The laminate simultaneously provides mechanical support, electrical insulation, and thermal reliability.

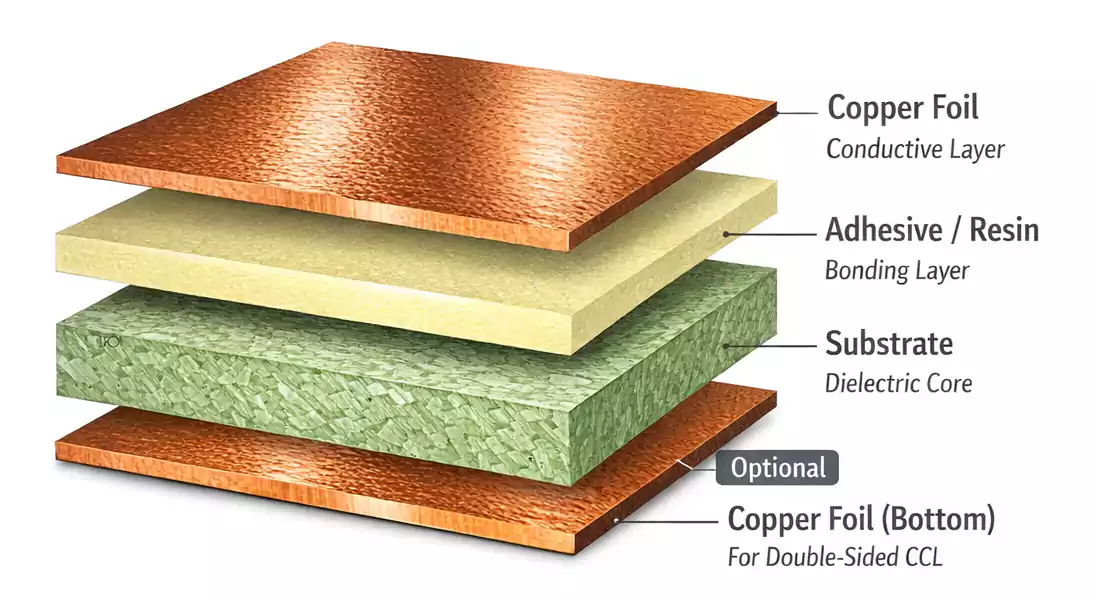

Key Components of CCL

A typical copper clad laminate contains:

- Copper foil: Acts as the conductive layer for trace and plane routing.

- Substrate: Often fiberglass-reinforced epoxy (e.g., FR-4) or other dielectrics.

- Adhesive or resin: Bonds copper to the substrate.

CCL can be laminated on one side (single-sided) or both sides (double-sided), depending on PCB design needs.

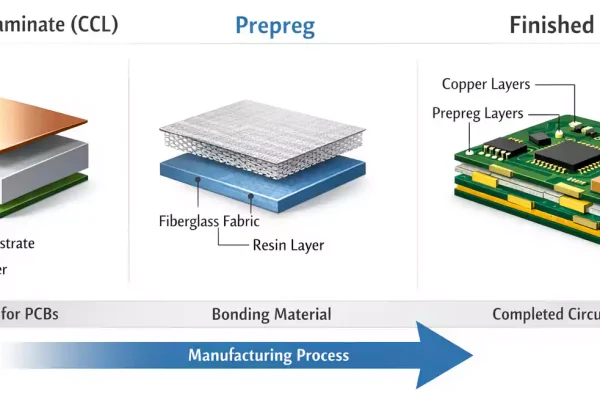

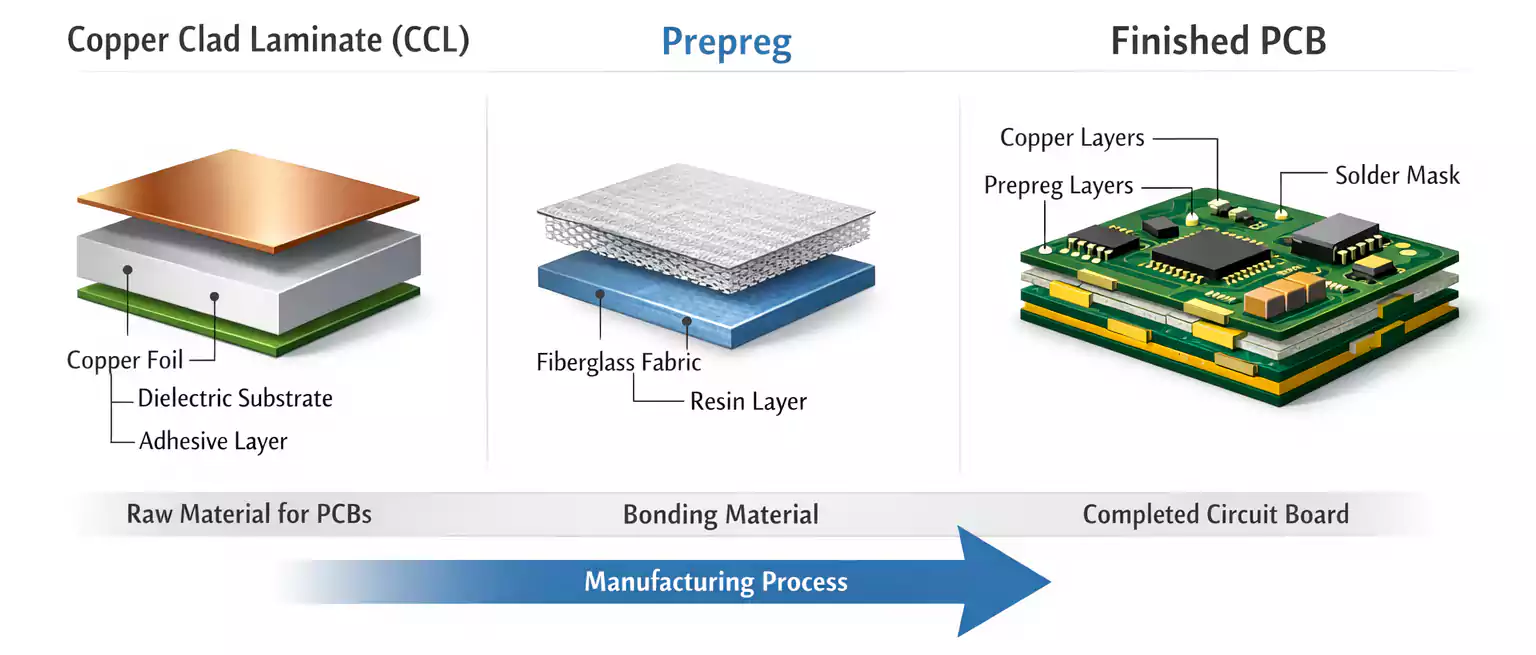

CCL vs. PCB vs. Prepreg: What’s the Difference?

People often confuse these terms:

- CCL (Copper Clad Laminate): The raw material used to make PCBs.

- Prepreg: A semi-cured resin sheet used to bond layers in multi-layer PCB stackups.

- PCB (Printed Circuit Board): The finished product created by processing CCL and prepreg into a functional board.

Think of CCL as the canvas where copper gets patterned into usable circuitry. Without it, PCBs wouldn’t exist.

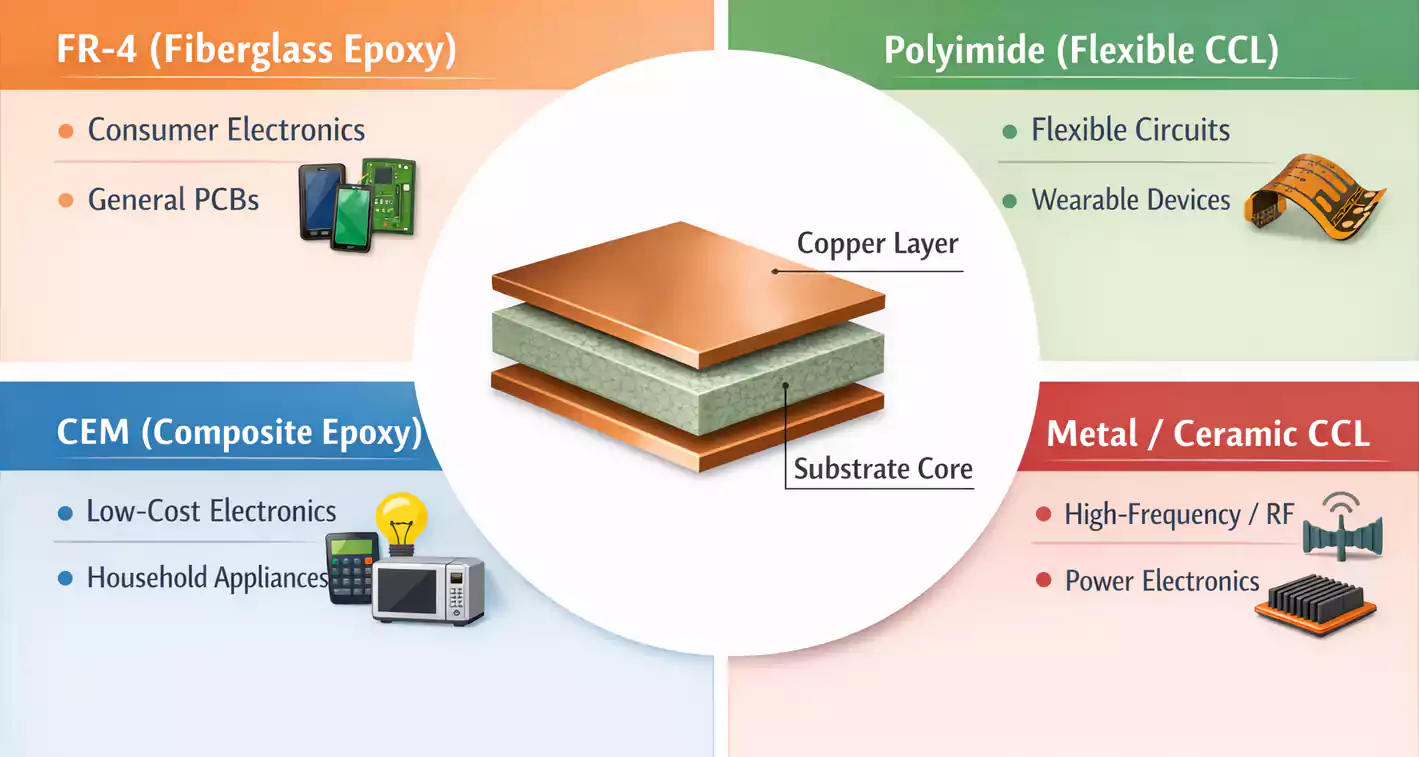

Types of Copper Clad Laminate

CCL comes in various types tailored for different applications. The most common ways to classify them include by substrate material, performance requirements, and mechanical properties.

1. Based on Substrate Material

- FR-4 (Fiberglass Reinforced Epoxy): The most widespread CCL type, known for good electrical properties, thermal stability, and affordability.

- CEM (Composite Epoxy Material): Paper/epoxy blends used in low-cost boards.

- Polyimide: Used in flexible or high-temperature boards.

- Ceramic & Metal-Backed: For high-frequency or power electronics requiring superior thermal management.

2. Rigid vs. Flexible

- Rigid CCL: Used in traditional rigid PCBs.

- Flexible CCL (FCCL): Built on flexible substrates (like polyimide) for bendable circuits.

Key Performance Characteristics

Selecting the right CCL means balancing electrical, thermal, and mechanical performance:

Electrical Properties

- Dielectric constant (Dk) and loss tangent (Df): Critical for high-speed signal integrity. Higher performance materials keep signal loss and impedance variation low.

- Copper conductivity: Materials with smoother copper and tighter thickness tolerances can improve high-frequency performance.

Thermal & Mechanical Properties

- Glass transition temperature (Tg): Indicates heat resistance, especially for reflow processes.

- Coefficient of Thermal Expansion (CTE): Affects reliability under temperature cycling.

CCLs for automotive or industrial applications often need higher Tg and lower CTE to ensure long-term reliability.

Copper Foil: More Than Just Thickness

Copper foil isn’t simply left or right — its type and surface treatment impact performance:

- Electrodeposited (ED) foil: Common in many PCB types.

- Rolled (RA) foil: Smoother surface for high-frequency applications.

- Surface treatments: Textures and coatings that improve adhesion or signal characteristics.

A rougher copper surface may improve adhesion but increase signal loss at high frequencies.

How to Choose the Right CCL

Here’s a practical guide to match CCL type with your application:

| Consumer Electronics | Standard FR-4 | Cost-effective, reliable |

| High-Speed Digital | Low Df / High Tg FR-4 | Signal integrity & thermal stability |

| RF & Microwave | PTFE or Specialty | Minimal signal loss |

| Power Electronics | Metal-Backed or Thick Copper | Thermal management |

| Flexible Products | Polyimide CCL | Bendability & durability |

Copper Clad Laminate Price: What Drives Cost?

One of the most common commercial searches is for copper clad laminate price, and it varies widely because costs depend on multiple parameters.

Key Price Factors

Price isn’t just about size:

- Material type: Standard FR-4 vs. high-frequency vs. metal-backed.

- Copper weight & treatment: Heavier or specialty foils cost more.

- Thickness and size: Larger and thicker sheets command higher prices.

- Raw material trends: Copper and resin price volatility directly impacts production costs.

- Certifications & specs: UL compliance, flame retardancy, and other quality validations.

Example Price Ranges

Typical commodity CCLs like FR-4 often range from $5 to $15 per square meter at standard performance levels, while high-performance laminates (for RF or high-speed boards) may exceed $200/m².

U.S. Market Pricing Examples

On online platforms and marketplaces, individual sheets of FR-4 CCL (e.g., custom sizes with ½-2 oz copper) sell for varying prices — for example, an 18" x 24" piece with heavier copper can be listed for around $69 or more.

Cost Optimization Tips

If cost is a driver but performance matters:

- Standardize board thickness and copper weight to industry-standard sizes.

- Avoid over-spec’ing materials beyond what your design requires.

- Plan for future revisions upfront to avoid costly redesigns.

Industry Standards & Material Specs

Standards help ensure consistent performance:

- IPC-4101: Defines laminate and prepreg material requirements.

- UL-94V-0: Flammability ratings for materials used in safety-critical applications.

Reading data sheets closely for Tg, CTE, Dk/Df, peel strength, and moisture absorption helps engineers compare apples to apples.

FAQs (Quick Answers)

Is FR-4 the same as CCL?

No. FR-4 is a type of CCL — one of many substrate materials used in laminate production.

What does “1 oz copper” mean?

It refers to copper weight per square foot (~35 µm thick), often used as a standard measurement.

Can I use the same CCL for a high-frequency design?

Standard FR-4 may work at moderate speeds, but high-frequency designs often require specialty laminates with lower dielectric loss.

Conclusion

Copper clad laminate (CCL) forms the foundation for PCBs, affecting signal performance, heat management, manufacturability, and cost. By understanding its structure, variables, and cost drivers, engineers and buyers align technical requirements with budgets.

Whether you’re looking for basic FR-4 panels or advanced high-speed laminates, mastering the basics of CCL selection and pricing is essential to successful PCB design and production.