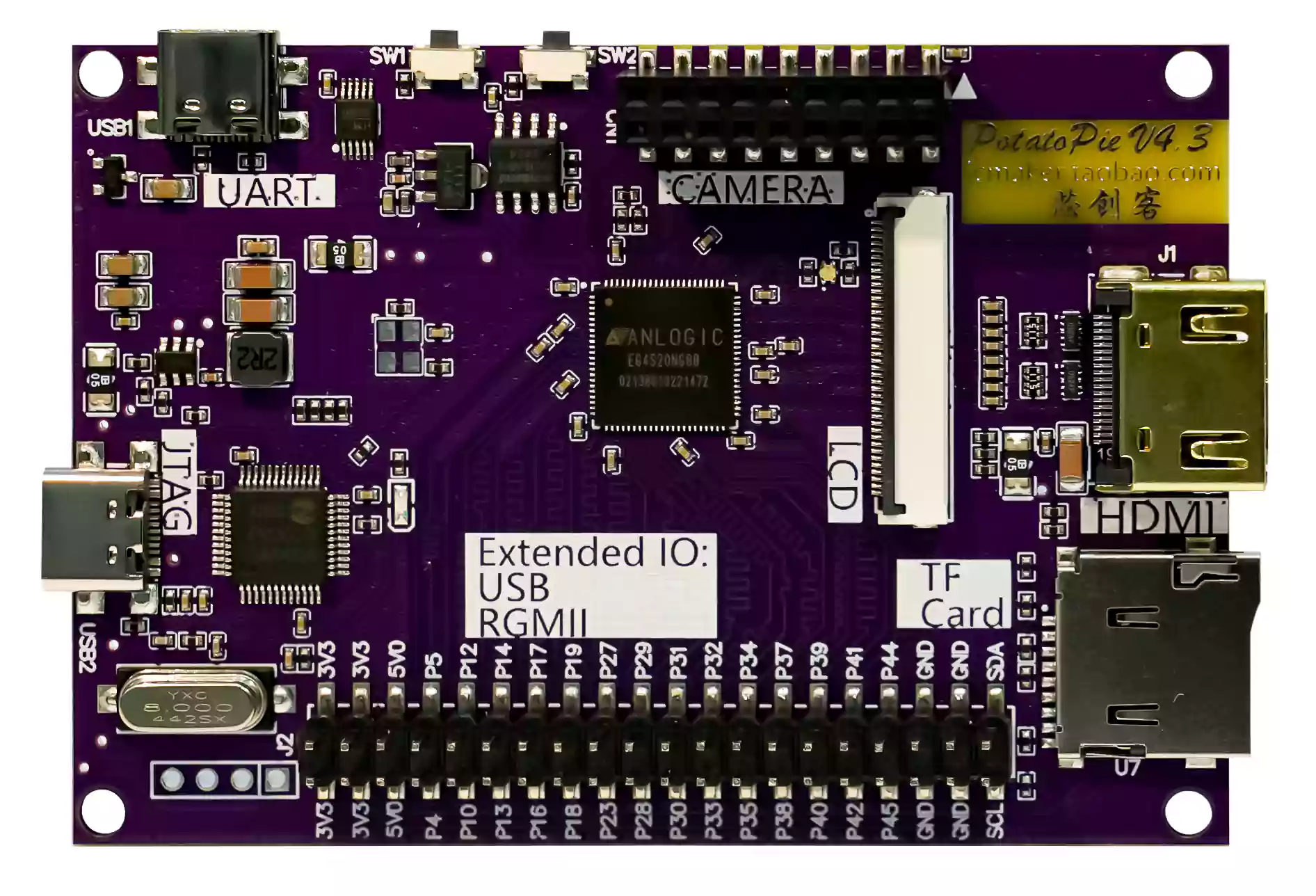

A Purple PCB is instantly recognizable—often associated with OSH Park’s signature look. While color doesn’t affect electrical performance, it does influence brand perception, readability, and manufacturability.

This guide explains what a purple PCB is, how solder mask color impacts ground-plane design and DFM considerations, and when it’s worth choosing purple over standard green.

What Is a Purple PCB?

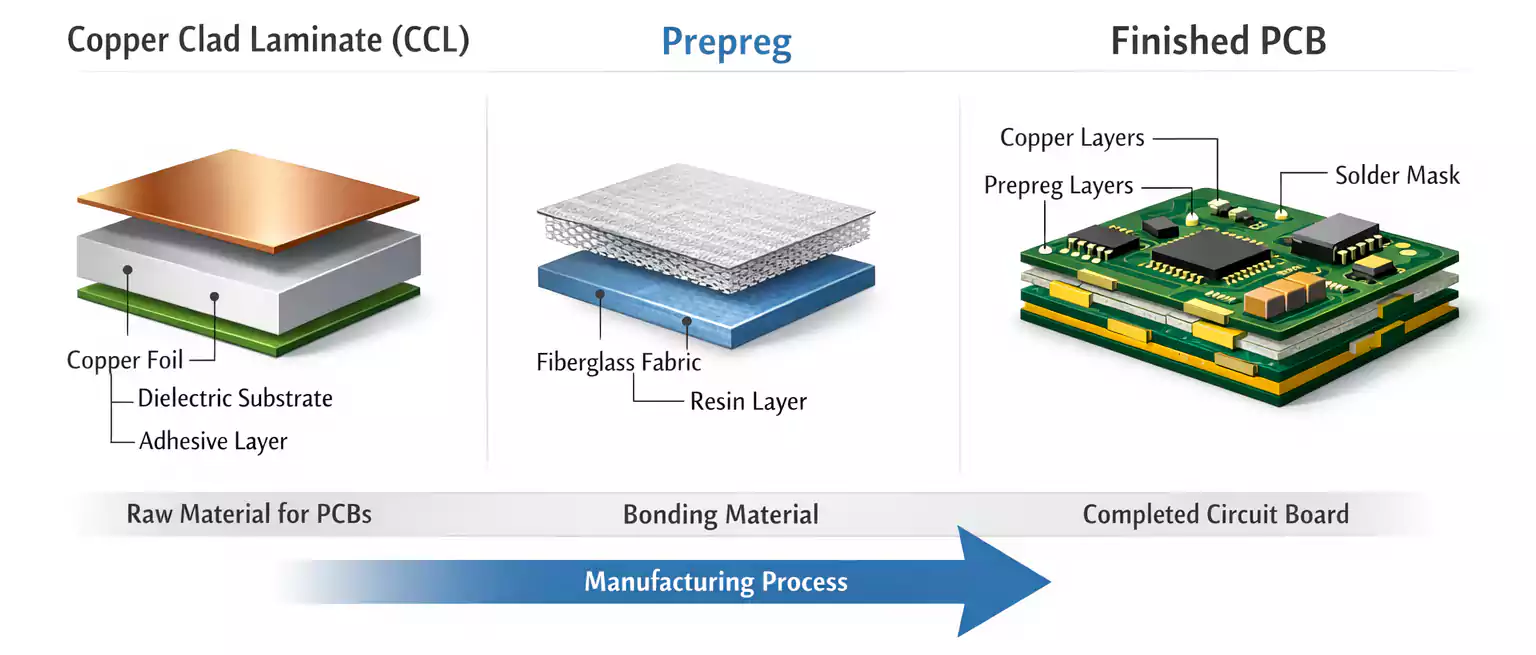

A purple PCB is simply a circuit board coated with a purple solder mask, the thin polymer layer that protects copper traces from oxidation, solder bridges, and mechanical damage.

The base laminate (typically FR-4 or a high-frequency material) remains the same regardless of color.

Solder masks are epoxy-based or photo-imageable polymers with added pigments for green, red, blue, black, white, or purple.

Color doesn't affect Dk or Df since the mask is thin and not part of the signal path. It mainly changes contrast, inspection, and finish options.

Why Purple? The Brand and Identity Factor

Color is an underrated branding tool in hardware.

For years, almost every PCB looked the same dull green. Then OSH Park turned the industry upside down by introducing vivid purple solder masks with ENIG finish, making hobbyist prototypes instantly recognizable.

That visual identity matters. Purple boards:

- Stand out in photos, demos, and crowdfunding campaigns.

- Signal creativity and premium craftsmanship.

- Help differentiate open-source hardware or consumer electronics lines.

If you want your board to look like a product, not just a prototype, purple is a strong visual choice. Many startups use color to create product tier separation — for instance, green for development kits and purple for production units.

Understanding the PCB Solder Mask

Before selecting a color, it’s worth revisiting what the solder mask actually does.

The solder mask (solder resist) is a protective coating applied over the etched copper layer.

Its purposes include:

- Preventing solder bridging during reflow.

- Shielding copper from oxidation and moisture.

- Improving appearance and surface smoothness.

- Defining SMD pad openings for accurate soldering.

Most modern PCBs use LPI (Liquid Photo-Imageable) solder masks.

Typical dry thickness after curing: 10–25 µm (0.4–1.0 mil).

The mask is exposed and developed to open windows for component pads and vias.

Green remains the manufacturing “comfort zone” because it cures uniformly, provides excellent contrast for Automated Optical Inspection (AOI), and maintains fine bridge widths—often as narrow as 4 mils between pads.

Other colors (including purple) may require slightly thicker or different resin formulations, which can affect the minimum feature capability.

Color Selection Principle 1 — Brand and Visual Psychology

Purple represents innovation, luxury, and creativity.

That’s why it’s common in consumer-facing or demo-oriented boards. When paired with a gold ENIG surface finish, the aesthetic is especially striking.

From a psychological perspective:

- Green = standard, reliable, mass production.

- Black = high-end or stealth.

- White = clean look for LEDs and smart home devices.

- Purple = unique, experimental, premium.

If your PCB is visible, paying extra for purple can make your product memorable.

Color Selection Principle 2 — Readability and Inspection

Solder-mask color changes how easily humans and machines can inspect a board.

1. Silkscreen and Label Contrast

On a purple background, the white silkscreen offers the highest readability.

Avoid gray or light yellow — they blend into the pigment and become unreadable under bright light.

2. AOI and Optical Contrast

Automated Optical Inspection systems rely on the contrast between copper, the mask, and the silkscreen.

Purple performs well but not perfectly:

- It provides better glare control than glossy black masks.

- However, unlike copper pads, the resistance is slightly lower than with green, which can make fine-pitch solder-bridge detection marginally harder.

Specifying matte-finish purple improves inspection by reducing glare.

3. Debug and Testing

For engineers probing ground nodes or tracing signals under a microscope, purple offers comfortable visibility without eye fatigue.

On densely packed boards, white or purple helps highlight routed signal paths better than dark black or glossy blue.

Color Selection Principle 3 — Yield and Manufacturability

Now the practical side: color does influence yield because each solder-mask pigment behaves slightly differently during curing.

1. Minimum Solder Mask Bridge

Most fabricators specify:

- Green: 4 mil (0.10 mm) minimum solder-mask dam.

- Other colors (including purple): 5 mil (0.125 mm) recommended.

That 1 mil difference might sound small, but for BGA packages or 0.4-mm-pitch parts, it can determine whether two pads merge during coating.

If using tight spacing, discuss color with your fabricator’s DFM engineer early.

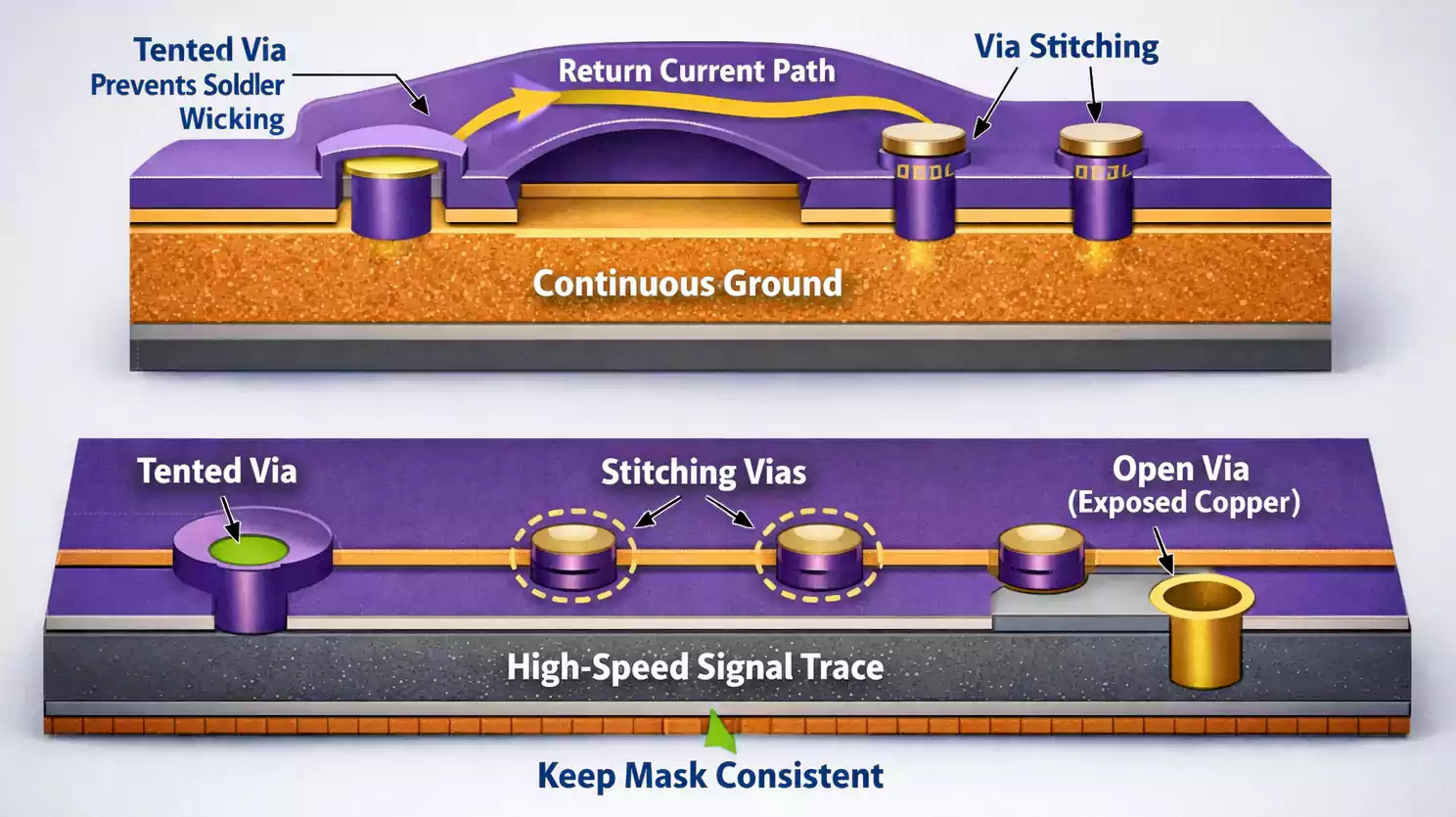

2. Impact on Ground-Plane and Return Paths

While solder-mask color doesn’t alter conductivity, mask openings over ground pours affect how solder flows and how copper remains exposed.

For example:

- Tent or cover via holes within a ground plane to prevent solder wicking.

- Keep the mask consistent across stitched vias to maintain uniform impedance and avoid tiny voids in the copper reference plane.

The purple pigment itself won’t change signal integrity, but mask design — open vs. tented — can influence EMC and current return path continuity, especially in high-speed or high-frequency layouts.

3. Adhesion and Cure Uniformity

Some non-standard colors require custom curing profiles.

If under-cured, the mask may blister during reflow; if over-cured, it may crack around the via holes.

This is where reputable manufacturers (like RayMing, ELEPCB, or FS Circuits) make a difference — they’ve already tuned their purple mask process for stable adhesion.

Cost and Supply-Chain Considerations

Let’s be honest — purple isn’t always the cheapest option.

- Material Cost: Non-green masks often carry a 10–20 % price premium because the ink is special-ordered.

- Lead Time: may extend by a few days if the color needs to be loaded or cleaned in separate coating equipment.

- Availability: small shops might only stock green by default; purple is typically available from mid- to large-scale fabricators or dedicated prototype services.

When Purple Is Worth It

Choose purple when:

- You want to differentiate a brand or product line.

- The board is visible to customers or investors.

- You’re building prototype batches or demo units where the extra cost is negligible.

When to Stick with Green

Stay with green when:

- You’re doing large-volume production where yield and throughput matter most.

- Your design uses very fine-pitch BGAs or 0.3-mm traces.

- You need short turnaround and standard processes.

Ground-Plane Design Meets Solder-Mask Strategy

Because many readers are here for “ground-plane basics,” let’s connect the dots.

1. Ground Plane Fundamentals

A ground plane provides a low-impedance return path for signals and helps reduce EMI. Key rules:

- Keep the plane continuous and unbroken under high-speed traces.

- Avoid splits that force return currents to detour.

- Use stitching vias to connect different ground areas.

2. How Solder Mask Interacts

- Tented Vias: covering ground vias with solder mask (purple or not) prevents solder fill and accidental shorts.

- Exposed Copper: In power or thermal areas, mask openings can improve heat dissipation but increase oxidation risk.

- Color Impact: darker masks like purple absorb more light, which slightly warms the surface during reflow but is negligible electrically.

3. DFM Tip for Purple Boards

Because purple masks may require wider bridges, avoid ultra-narrow solder-mask dams between ground pads or shielding vias. Keep spacing ≥ 5 mil where possible.

FAQ

Does a purple PCB perform better electrically?

No. Electrical parameters are determined by the dielectric (FR-4, Rogers, etc.), not by mask pigment. The mask is too thin to alter impedance or loss.

Why do some engineers say purple looks “premium”?

Because of visual branding. OSH Park and other high-end prototype services popularized it, so customers associate purple with quality and craftsmanship.

Is purple harder to inspect?

Not necessarily. With a white silkscreen and matte finish, it’s perfectly readable. AOI systems calibrated for non-green masks handle it well today.

Does it affect solderability?

As long as the mask is properly cured and pad openings are accurate, solder wetting is identical to green.

Why do some manufacturers charge more?

Because they must change coating lines, clean machines, and stock special pigments. That adds setup time and waste.

Conclusion

A purple PCB isn’t just about aesthetics — it reflects thoughtful design and brand identity.

Technically, it performs like any standard board. Visually, it sets your product apart.

By following proper DFM practices — such as proper solder mask spacing and contrast — you can achieve both solid reliability and a distinctive look.

Next time you design a board, don’t overlook color. Green is standard. Purple is unforgettable.