Fast Turn PCB provides turnkey value-added services that go beyond basic PCB production to help customers accelerate time-to-market and streamline their supply chain. Our comprehensive solutions include custom mold making, plastic injection molding, and cable assembly, along with essential services such as IC programming, ICT, FCT, and aging tests—all integrated under one roof to ensure speed, consistency, and quality.

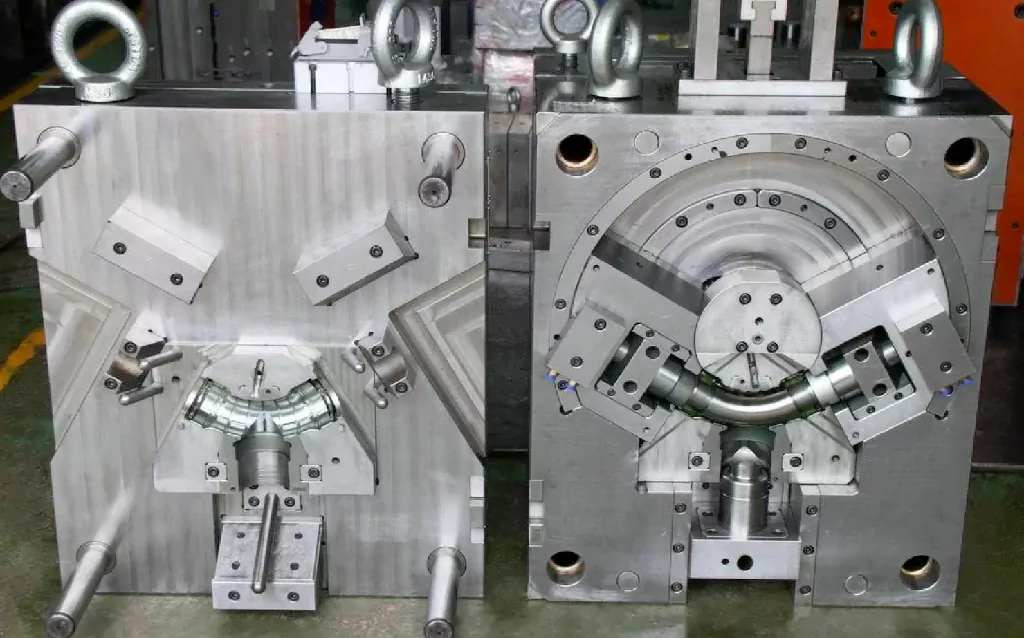

Precision Mold Design & Manufacturing

Mold making is the foundation of any plastic housing or structural part. Our experienced team provides:

Product design evaluation and optimization

High-precision mold fabrication (multi-cavity, hot runner, overmold, etc.)

Moldflow simulation to ensure manufacturability

Fast lead times and ongoing maintenance services

With advanced CNC machining and EDM equipment, we deliver highly accurate, durable molds for both prototyping and mass production, ensuring long-term consistency and performance.

Plastic Injection Molding: Consistent, Scalable, High-Quality

We provide end-to-end plastic injection molding services, covering everything from material selection to surface finishing:

Materials: ABS, PC, PA, PBT, TPU, and more

Multi-color, overmolding, and insert molding capabilities

Finishing options: painting, silk screening, laser engraving

Our injection molding facility follows strict quality control protocols to deliver flawless, production-grade parts with reliable mechanical properties and excellent aesthetics.

Custom Cable Assembly: Reliable Connectivity, Streamlined Integration

Wiring and interconnection are essential for functional electronic devices. Our custom cable assembly services include:

Wire harnesses, ribbon cables, FPCs, USB, DC, and custom power/signal cables

Automated cutting, stripping, crimping, and termination

100% electrical testing to ensure signal integrity

Ready-to-integrate cables for streamlined product assembly

We manufacture cables to your specifications, ensuring compatibility with your devices and compliance with UL, ISO, or other regulatory standards.

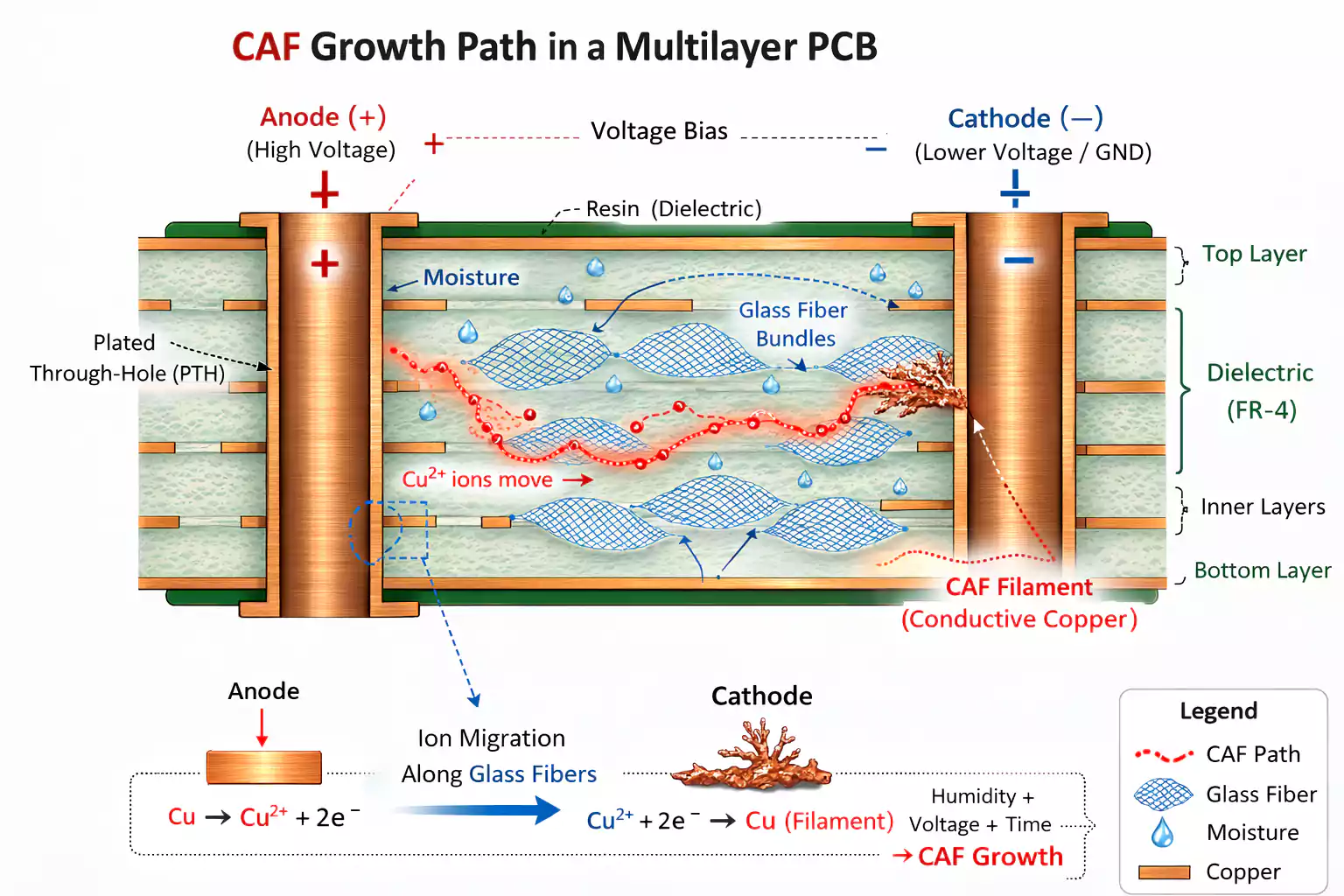

Electrical Testing & Programming Services (IC Programming, ICT, FCT, Aging Test)

Beyond structural and connection components, we provide key electrical services as part of our turnkey offering:

IC Programming – Automatic chip programming for MCUs, EEPROMs, Flash, and more

ICT (In-Circuit Testing) – Validates solder joints and basic circuitry

FCT (Functional Testing) – Simulates actual use cases to verify full functionality

Aging Test – Performs stress and burn-in tests to ensure long-term reliability

These services ensure that your products are tested, verified, and production-ready before shipment.

Why Choose Our Turnkey Manufacturing Services?

Our turnkey approach helps electronics brands and hardware teams:

Accelerate product development – From concept to finished unit with fewer handoffs

Reduce costs – Eliminate the need to manage multiple suppliers

Improve product consistency – Centralized production ensures unified quality control

Scale efficiently – Support from prototyping through full-volume production

Conclusion

From custom mold design and plastic injection to cable manufacturing and functional testing, our turnkey value-added services are designed to help you deliver better products, faster. Whether you're a startup building your first prototype or an established brand scaling up a global launch, we provide the integration, quality, and flexibility you need.

Looking for a turnkey electronics manufacturing partner? Get in touch today to discuss how we can support your next project from concept to completion.