In addition to common resins, many other chemistries are used in PCB substrates. When selecting a resin, designers and fabricators must balance performance and cost, which are influenced by raw materials, processing costs, manufacturing methods, and downstream PCB processes.

1. Epoxy Resin Blends

Epoxy resins blended with other resin systems have been widely developed to meet the needs of high-end applications that exceed the performance limits of standard epoxy-based substrates.

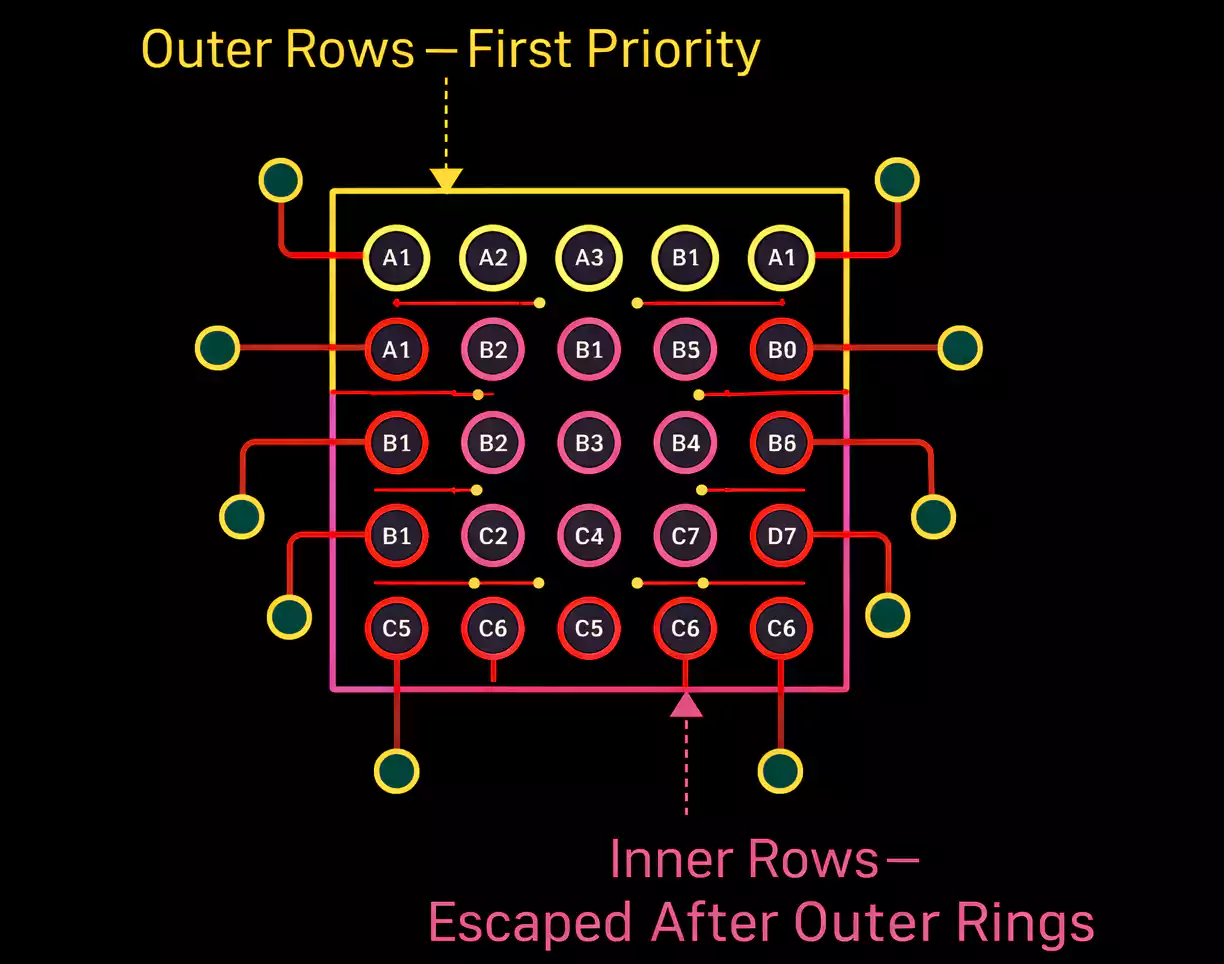

Although these advanced materials are more expensive, the primary driver for their use is the demand for improved electrical properties—particularly lower dielectric constant (Dk) and dissipation factor (Df)—to support high-frequency circuit operation.

Common epoxy blends include:

- Epoxy–PPO (polyphenylene oxide)

- Epoxy–Cyanate Ester

- Epoxy–Isocyanurate

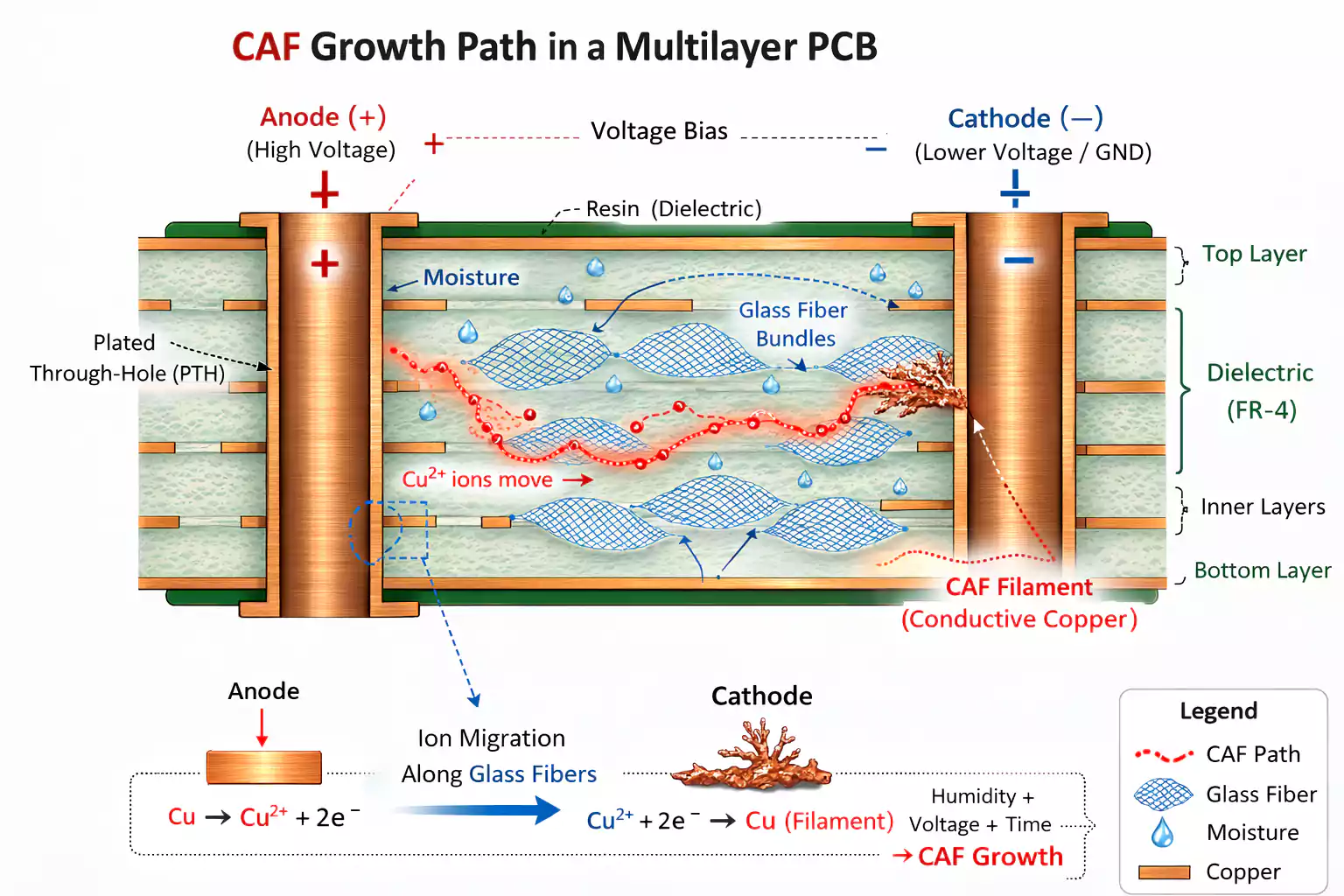

Thanks to process optimization, the impact of these materials on standard PCB manufacturing has been significantly reduced. However, specialized process control is still required during multilayer lamination, drilling, desmearing, and hole wall preparation.

Epoxy resin blends are primarily used in high-frequency and high-speed applications, such as antennas, RF and wireless communication devices, high-performance computing, and high-speed Ethernet systems.

2. BT (Bismaleimide-Triazine)/Epoxy

In most cases, epoxy resin is used as a modifier and blended into BT resin. As a result, these materials are typically classified as epoxy hybrid resins. BT/epoxy resin systems generally have a glass transition temperature (Tg) ranging from 180°C to 300°C, and they offer a well-balanced combination of excellent electrical, thermal, and chemical resistance properties.

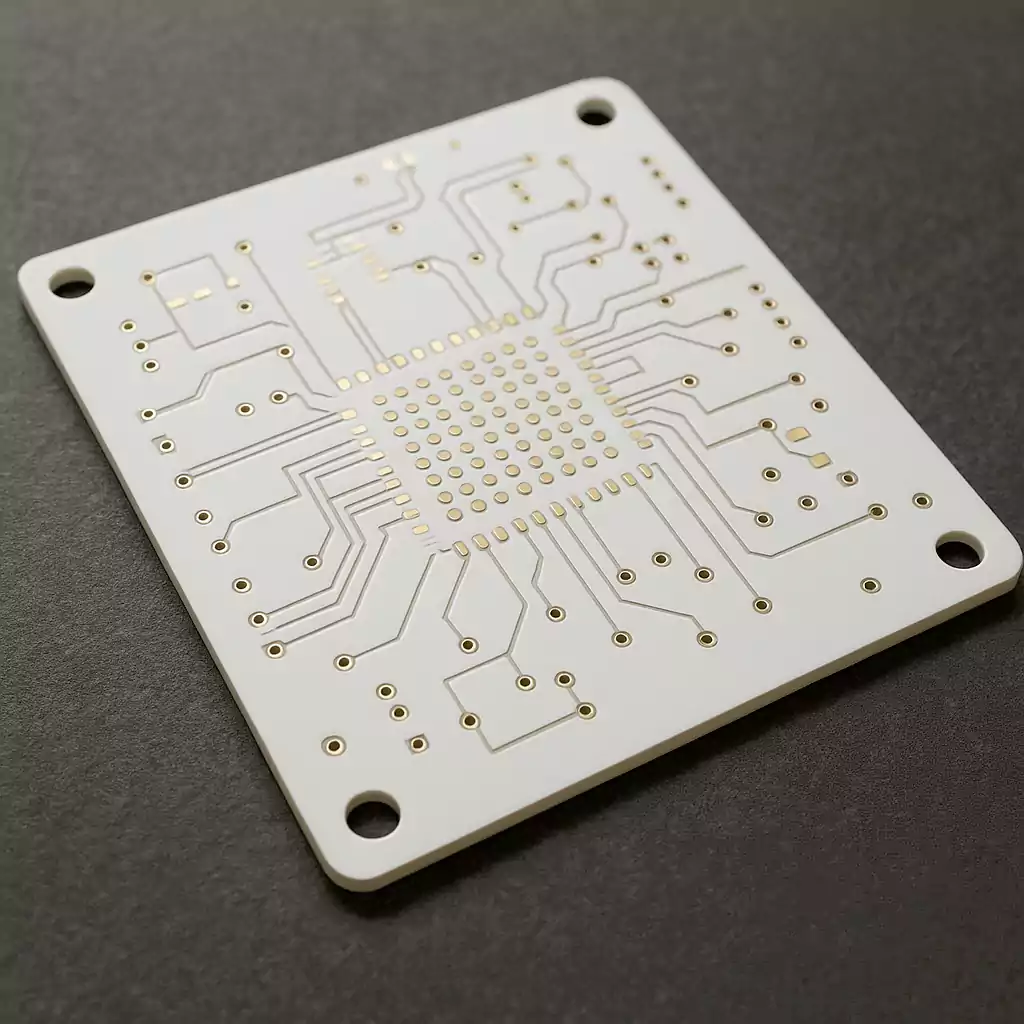

BT/epoxy materials meet many of the demanding requirements for semiconductor packaging, making them a common choice for BGA substrates and chip packaging base materials. They are also well-suited for fabricating high-density multilayer PCBs that require high thermal, electrical, and chemical performance.

However, BT-based materials come with some trade-offs—cost being the most significant. The higher the BT content, the more expensive the material becomes. Additionally, BT laminates tend to be more brittle and have higher water absorption than standard epoxy-based laminates.

3. Cyanate Ester

Cyanate ester resins offer very high Tg (around 250 °C), excellent electrical properties, strong high-temperature mechanics, and good thermal stability. Their flexural and tensile strengths surpass those of difunctional epoxies. However, neat (unmodified) cyanate ester is costly and requires specialized processing, increasing overall manufacturing costs.

With modified cyanate esters (e.g., bisphenol-A cyanate ester), cure temperatures can be reduced to ~170 °C, and resistance, flame retardance, and adhesion are improved. Modifications increase brittleness, so toughening is usually added.

Blending cyanate ester with epoxy improves processing and lowers cost, enabling use in high-frequency PCBs. Today, application areas largely overlap with epoxy-PPO, including high-frequency/high-speed communications and high-performance electronics.

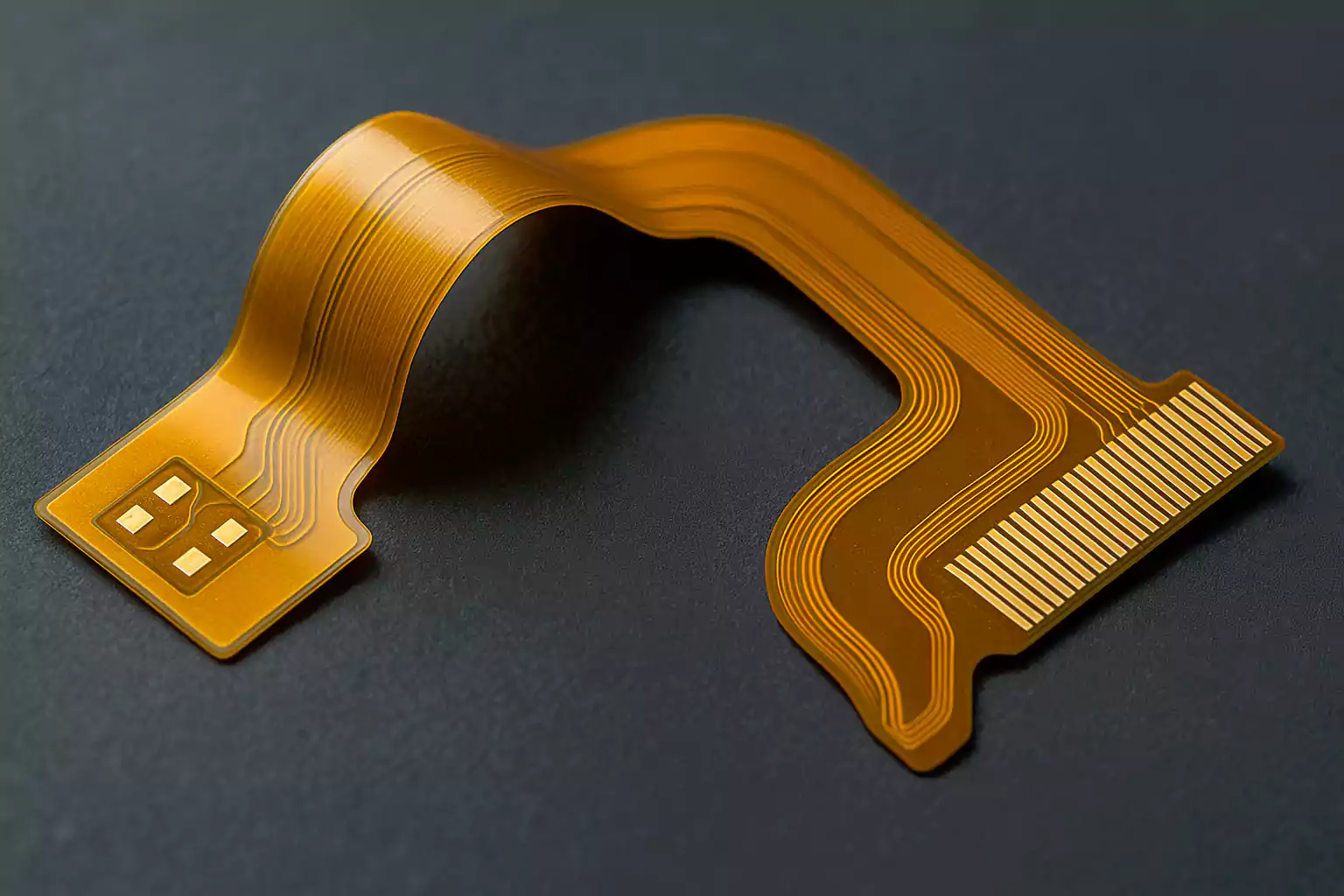

4. Polyimide (PI)

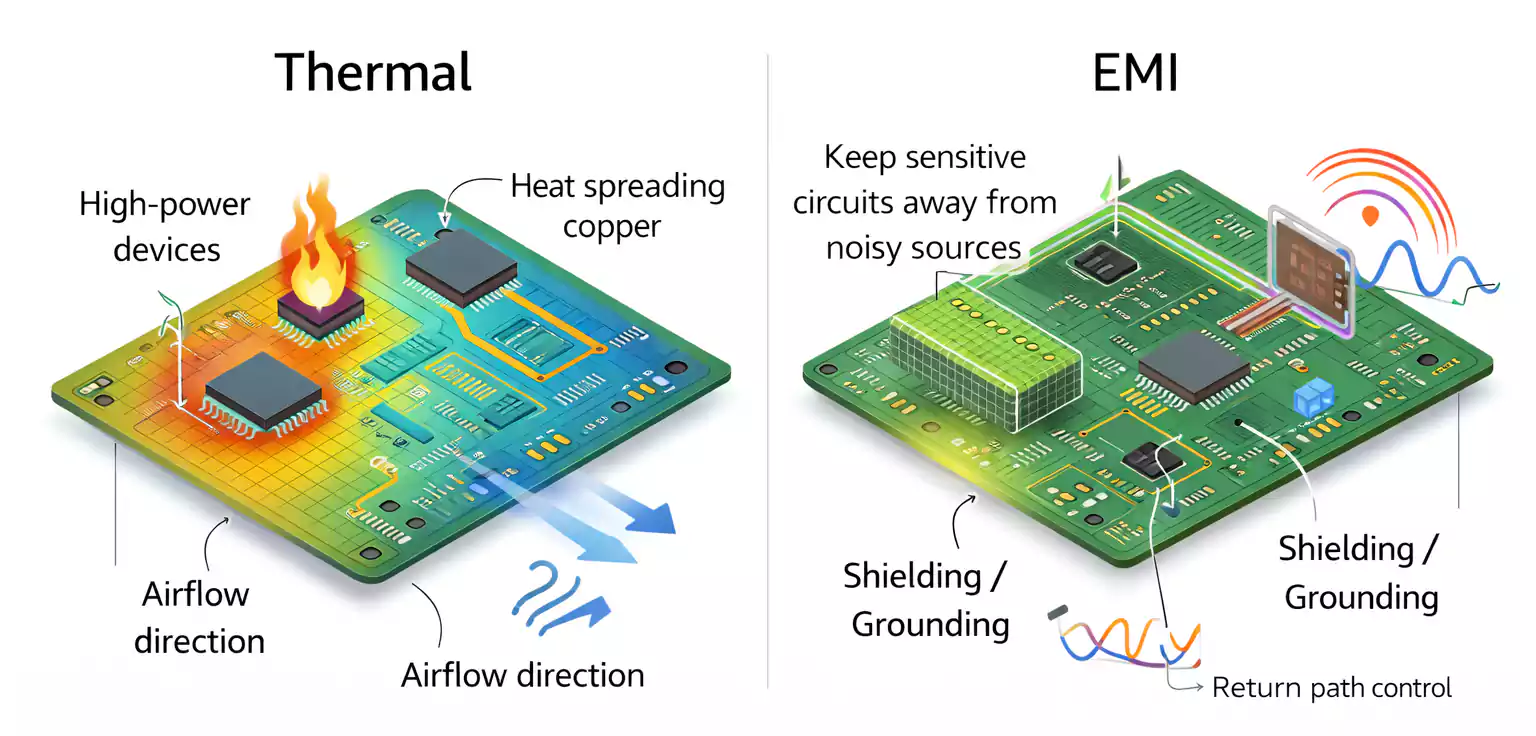

Polyimide resin offers exceptional heat resistance. The glass transition temperature (Tg) of pure polyimide substrate is approximately 260 °C, while modified or toughened polyimide substrates have a Tg around 220 °C. It also has a very high thermal decomposition temperature, providing excellent thermal reliability. A high Tg helps reduce thermal expansion since most thermal expansion occurs below Tg and remains minimal.

This material is commonly used in circuit boards that require high resistance to aging and extreme temperatures—such as aerospace electronics, oil drilling equipment, and military systems where thermal performance is critical.

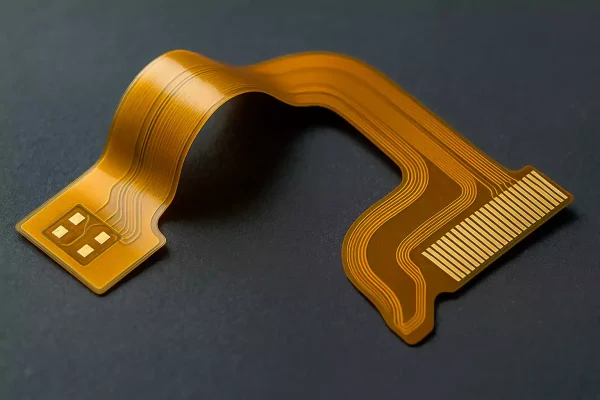

However, polyimide materials are also very expensive and challenging to process, which limits their use to specialized applications. In current high-volume production, polyimide is mainly used in flexible base materials, such as flexible copper-clad laminates (FCCL).

5. PTFE (Polytetrafluoroethylene, “Teflon”)

PTFE substrates are used where top-tier electrical performance is mandatory. These materials demand highly specialized processing and are expensive. To manage costs, PTFE is often used in hybrid stackups—only certain layers use PTFE, while others use lower-cost conventional materials—so the overall board cost stays under control while meeting critical RF performance requirements.

6. PPE (Polyphenylene Ether)

PPE offers better electrical and thermal performance than epoxy. It’s well-suited for RF, wireless, and high-speed computing products. Early PPE formulations were complex to process, but later adjustments to resin recipes and rheology made it compatible with standard PCB lines with only minor process tuning.

Other Resin Types and Formulations

As shown above, molecular structure significantly shapes laminate properties. To meet new performance needs in the PCB industry, engineers have researched and adopted many new resins, each offering clear, distinct characteristics.

Therefore, development focuses more on material properties and manufacturability than on reaction chemistry or polymer synthesis. For PCB engineers and fabricators, the emphasis is on electrical/thermal/mechanical properties and process behavior—how the material drills, laminates, plates, bonds, absorbs moisture, and survives assembly.