In today’s rapidly evolving electronics industry, innovation drives the need for smaller, lighter, and more efficient devices. Flexible Printed Circuits (FPC), also known as flexible PCBs, are essential to this advancement. These highly adaptable circuits allow for complex electronic designs in compact spaces. But what exactly are FPCs, and why are they so important? In this guide, we’ll dive into the details of FPC technology, its applications, and the key benefits it offers.

What Is an FPC?

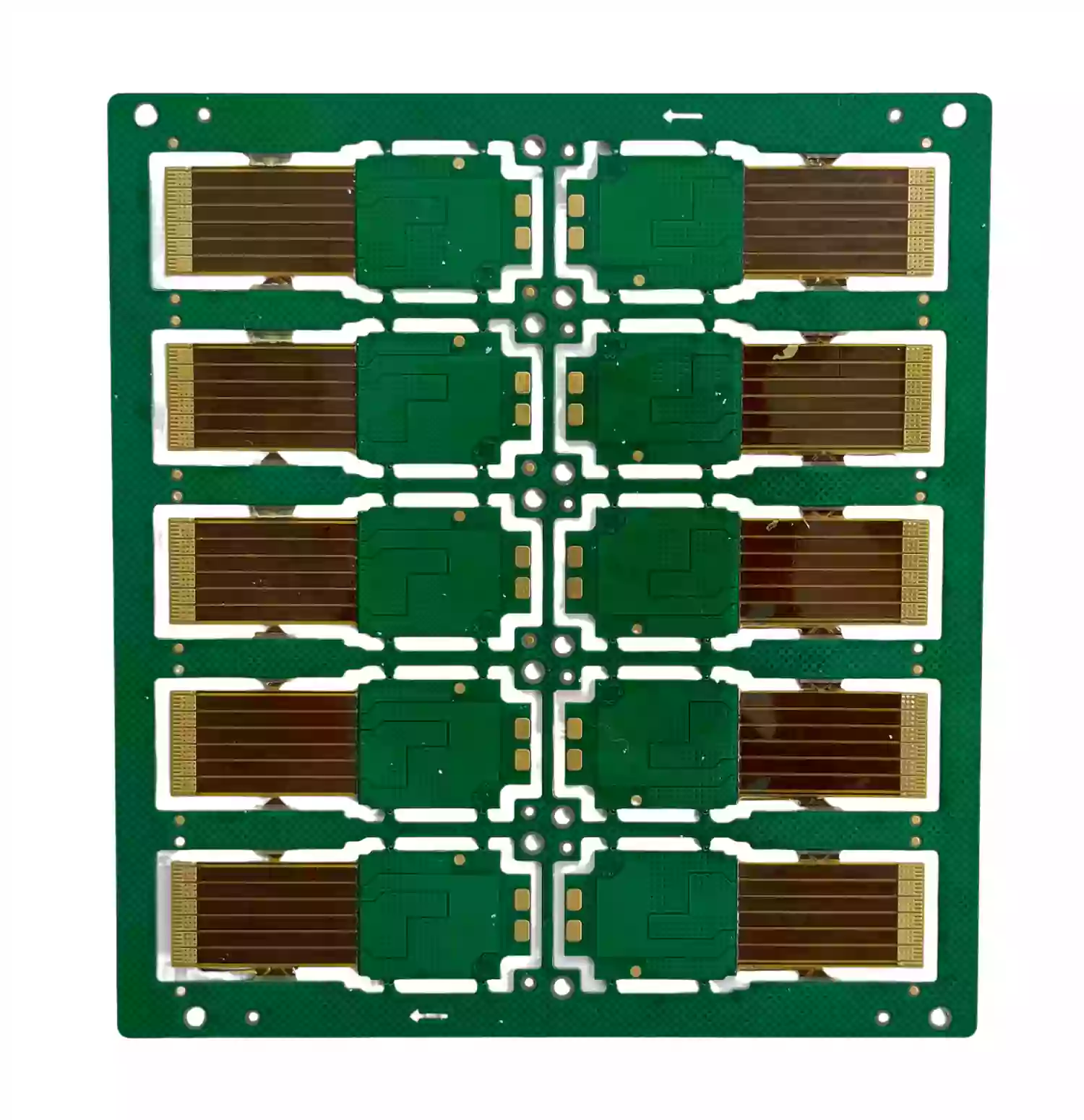

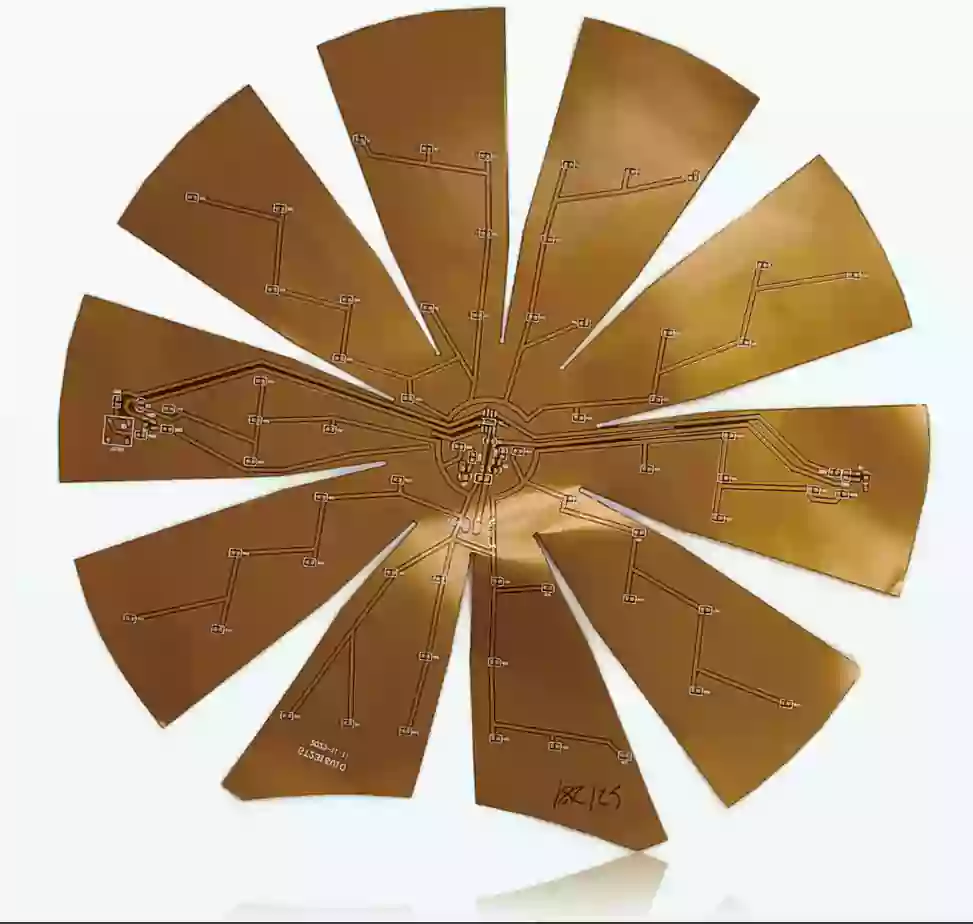

A Flexible Printed Circuit (FPC) is a type of PCB (Printed Circuit Board) designed to bend, fold, and twist without compromising its functionality. Unlike traditional rigid PCBs, FPCs are made from flexible materials, such as polyimide, and use copper foil to create electrical pathways.

Key Materials of FPC:

Polyimide: The flexible base material that allows the PCB to bend and flex.

Copper Foil: The conductive material used to create circuit traces.

Adhesives: Special adhesives are used to bond the layers of the circuit together.

Types of FPC:

Single-Sided: A basic design where the circuit is only on one side.

Double-Sided: A more advanced design where the circuit is placed on both sides.

Multilayer: Multiple layers of circuits stacked together for high-performance applications.

Applications of FPCs

Flexible PCBs have become integral to the design of many modern electronics. They can be found in:

Wearables: Smartwatches, fitness trackers, and medical devices require flexible circuits due to their small size and ability to conform to the human body.

Smartphones and Tablets: Flexible circuits are used in displays, batteries, and connectors, allowing for more compact, slim designs.

Automotive Systems: FPCs are utilized in critical automotive applications, from dashboard electronics to sensors.

Medical Devices: From pacemakers to hearing aids, FPCs ensure that medical devices can function effectively in dynamic environments.

Benefits of Using FPCs

There are many reasons why engineers and designers prefer FPCs in modern electronics. Here are some of the key benefits:

1.Design Flexibility: Flexible PCBs can easily bend, fold, or twist to fit the unique shapes of devices, allowing for more creative and compact designs.

2.Space Saving: FPCs enable designs that save significant space compared to traditional rigid PCBs. Their ability to be placed in 3D configurations makes them ideal for compact electronics.

3.Enhanced Reliability: FPCs are less prone to cracking and damage due to their ability to bend and absorb shocks and vibrations, making them ideal for use in dynamic environments.

4.Improved Heat Dissipation: Flexible circuits can be designed to distribute heat more effectively, which is crucial for high-performance electronics.

How to Choose the Right FPC Manufacturer

When choosing a manufacturer for your FPC, consider the following factors:

Certifications: Look for manufacturers with industry-standard certifications like IATF16949, ISO9001, and UL to ensure quality and compliance.

Capabilities: Ensure the manufacturer can meet your specific needs, such as multiple layers, min trace widths, and impedance control.

Turnkey Services: A manufacturer offering complete design and production services ensures a smooth process from concept to final product.

Conclusion

Flexible Printed Circuits are revolutionizing the way electronic devices are designed and built. Their unique ability to bend and fit into compact spaces is critical to the development of advanced, high-performance products. Whether you're designing wearable devices or automotive systems, FPCs are the future of electronics. Choose a reliable FPC manufacturer that understands your needs and offers high-quality, innovative solutions for your projects.