Comparing Surface Mount Technology vs Through Hole

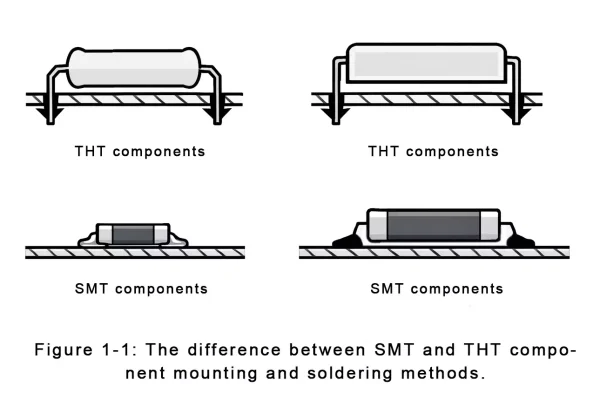

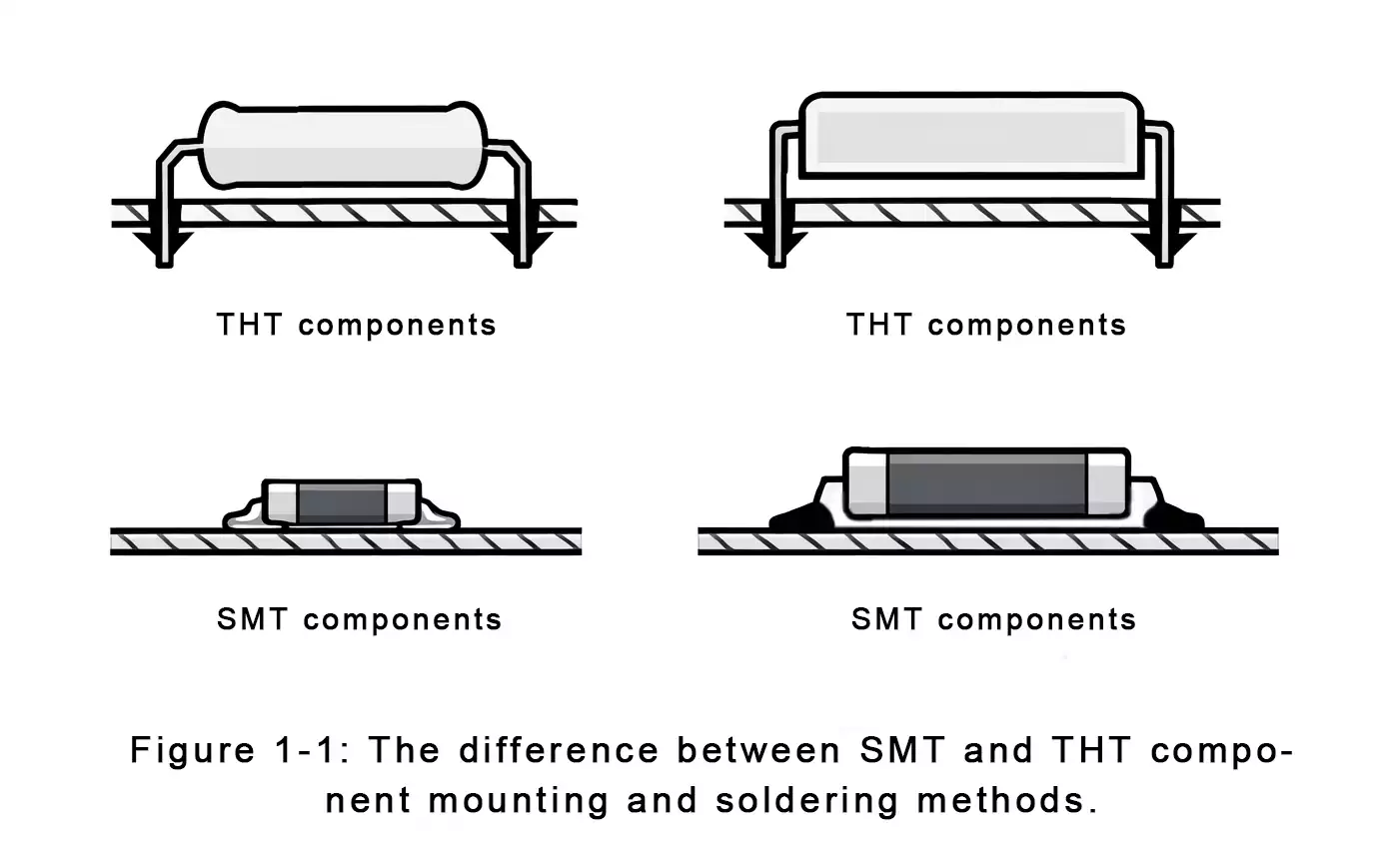

The characteristics of Surface-Mount Technology (SMT) are best illustrated by comparing it with traditional Through-Hole Technology (THT). From a process perspective, the fundamental difference between the two lies in “mounting” versus “inserting.” Their distinctions also extend to the substrate structure, component configuration, assembly form, solder joint shape, and overall assembly process.

THT uses leaded components that are inserted into pre-drilled holes on a printed circuit board (PCB) and soldered on the opposite side through wave soldering or similar methods. The component bodies and solder joints are distributed on opposite sides of the PCB. Because the leads are relatively long, once circuit density increases, it becomes difficult to further reduce product size. In addition, closely spaced leads can cause failures, and long leads are prone to signal interference.

SMT places chip-style or miniaturized components directly on the PCB. Solder joints form through reflow or wave soldering. Both the components and solder joints are on the same board side. Through-holes mainly connect circuit layers on an SMT PCB. Their number and diameter are greatly reduced. This enables much higher assembly density.

Due to differences in component structure and lead configuration, these two distinct assembly methods—“insertion” and “mounting”—have evolved. This transformation in assembly technology has enabled PCB-level modules and ceramic substrate assemblies to achieve significant improvements in both functionality and performance, while dramatically reducing size and weight.

Key Advantages of Surface Mount Technology vs Through Hole

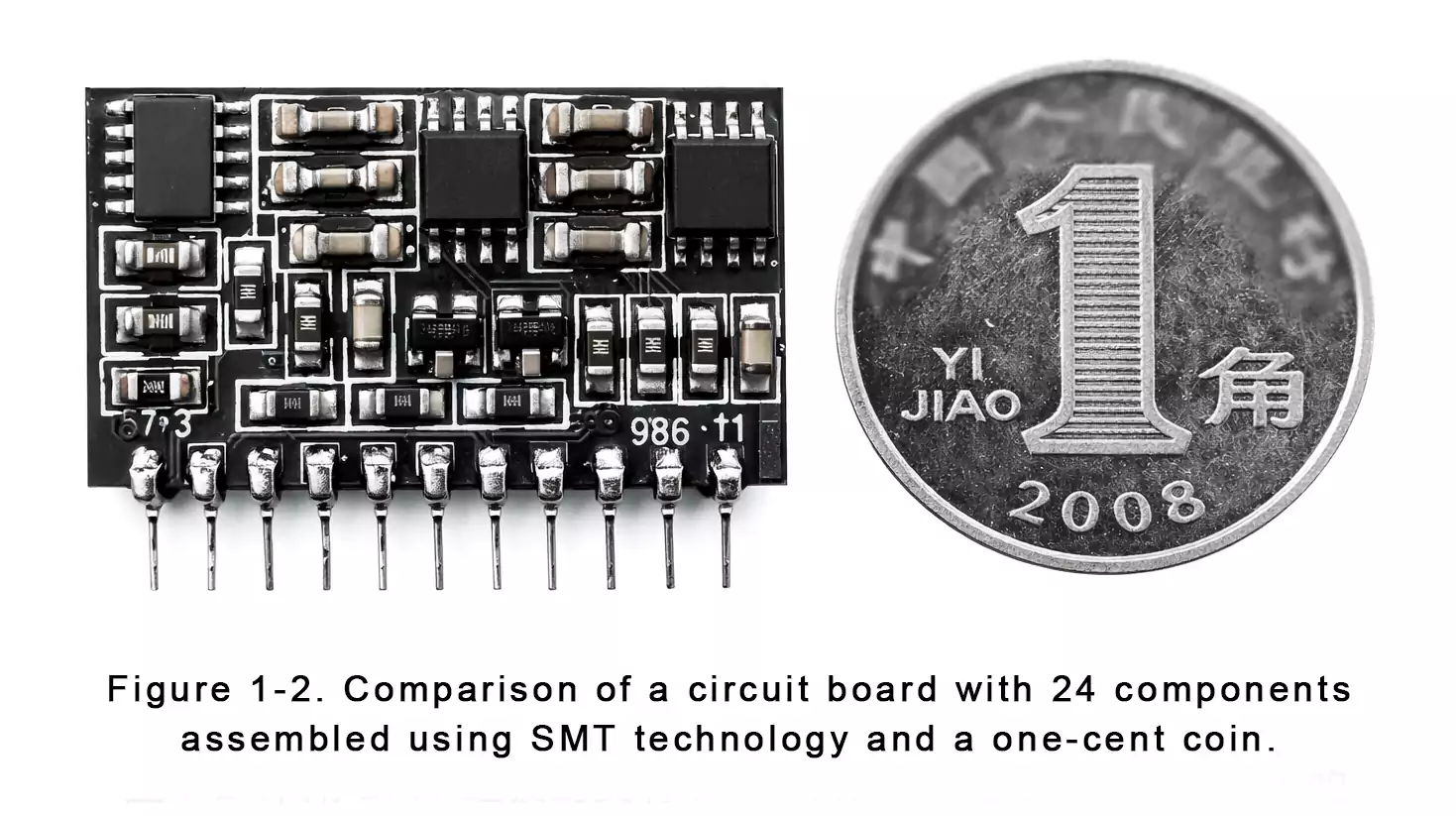

1. Miniaturization and Weight Reduction

SMT components are much smaller and use less space than THT components. Overall dimensions can be reduced by 60–70% and, in some cases, up to 90%, while weight can be reduced by 60–90%.

2. Higher Assembly Density and Faster Signal Transmission

When components are mounted on both sides of a PCB, the assembly density can reach 5.5–20 solder joints per cm². Because interconnect traces are shorter, signal delay is minimized, resulting in faster signal transmission. SMT assemblies also offer better resistance to vibration and shock, which is particularly important for high-speed electronic devices.

3. Improved High-Frequency Performance

Since SMT components have no or very short leads, circuit parasitics are significantly reduced, minimizing radio-frequency (RF) interference and enhancing high-frequency characteristics.

4. Better Automation, Reliability, and Productivity

With standardized and serialized component sizes and consistent soldering conditions, SMT is well-suited to automation. The reduced likelihood of component damage during soldering leads to higher yields and greater reliability.

5. Lower Material and Manufacturing Costs

With advances in equipment efficiency and reduced packaging material consumption, the packaging cost of most SMT components—and therefore their market price—is now lower than that of equivalent THT components.

6. Simplified Production Process and Lower Overall Cost

SMT eliminates steps such as lead forming, bending, and trimming. This shortens production cycles, increases throughput, and can reduce total manufacturing costs by 30–50% compared with through-hole assembly.

In summary, surface-mount technology excels in assembly density, performance, reliability, automation, and cost efficiency, making it the leading choice in modern electronics manufacturing.