In modern electronics manufacturing, SMT (Surface Mount Technology) has become the cornerstone of PCB assembly and PCBA production.

As electronic products evolve toward higher density, smaller size, and greater reliability, SMT has replaced traditional Through-Hole Technology (THT) and developed into a comprehensive, highly integrated engineering discipline.

This article provides a practical overview of what SMT is, what it includes, and why it matters—helping engineers and professionals better understand the technological foundation behind today’s PCBA manufacturing.

The Role of SMT in Modern PCBA Manufacturing

In the early days of electronics, Through-Hole Technology dominated the industry.

However, as circuit complexity and frequency increased, THT gradually exposed several limitations:

- Large component size and low routing density

- Limited automation capability

- Poor suitability for high-frequency, high-speed applications

By allowing components to be directly mounted on the PCB surface, SMT dramatically improved assembly density, manufacturing speed, and reliability.

Today, nearly every electronic device relies on SMT as its primary assembly process.

SMT: More Than Just “Soldering Components.”

SMT is often simplified as “surface-mount soldering,” but in practice, it is far more than that.

From an engineering standpoint, SMT is a multidisciplinary system that integrates several interdependent elements:

- Surface-mount components

- Printed circuit boards (PCB)

- Assembly design (DFM/DFA)

- Assembly materials and process technology

- Inspection and rework methods

- Production equipment, control, and management

Each of these factors influences the others.

Together, they form the complete ecosystem that determines product yield, performance, and reliability in modern PCBA production.

Core Elements of Surface Mount Technology

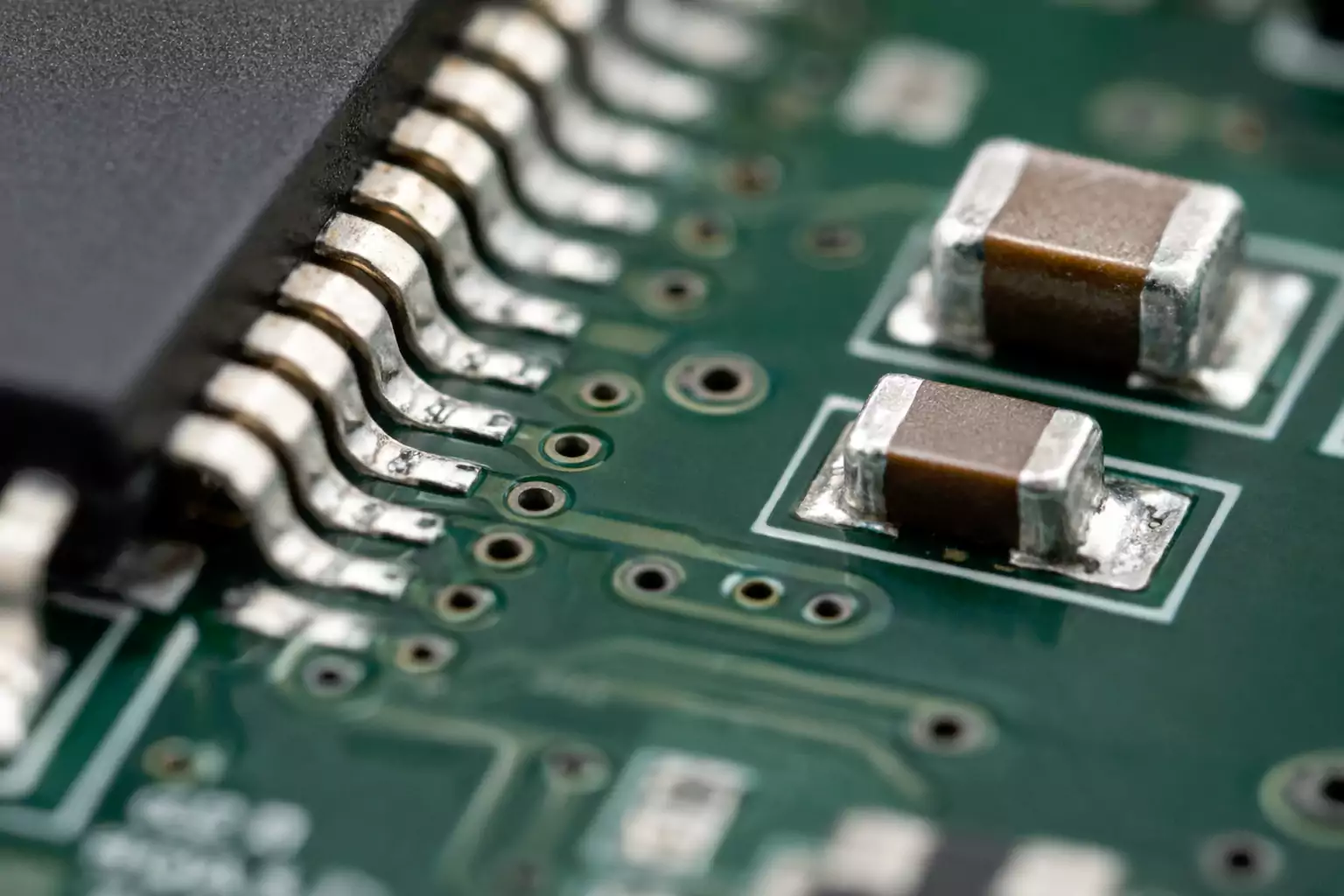

1. Surface-Mount Components (SMC/SMD)

The foundation of SMT lies in surface-mount components.

Compared with traditional through-hole parts, SMDs are smaller, lighter, and optimized for automated production.

They feature short or no leads, reducing parasitic effects and improving high-frequency performance.

Common types include:

- Chip resistors and capacitors

- Integrated circuit packages such as QFP, BGA, and CSP

These components must meet strict requirements for heat resistance, solderability, and dimensional accuracy to ensure process stability.

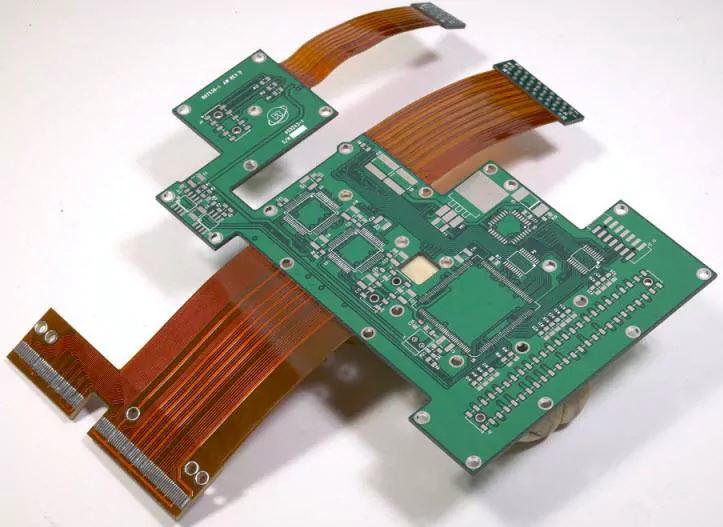

2. Printed Circuit Boards (PCB)

PCBs serve as the structural and electrical base for SMT assembly.

Different PCB types have a direct impact on process performance:

- Single-layer and multilayer PCBs

- Rigid, flexible, or metal-core PCBs

- Ceramic substrates for high-frequency applications

PCB flatness, pad geometry, and surface finish all affect solder paste printing accuracy, placement precision, and joint reliability.

In SMT manufacturing, the PCB is not just a carrier—it is an integral part of the process system.

3. Assembly Design (DFM / DFA)

Design for Manufacturability (DFM) and Design for Assembly (DFA) connect product design with real-world production.

A well-engineered SMT layout considers:

- Logical component placement

- Pad sizing and spacing

- Electrical and thermal management

Good assembly design minimizes production risks, enhances yields, and ensures that the PCB layout supports consistent, high-quality soldering.

4. Engineering Layers of SMT Process Technology

SMT is not a single technique—it is a hierarchical system of interrelated technologies, typically divided into four major layers:

- Material Technology – solder paste, flux, adhesives, and cleaning agents

- Process Methods – printing, dispensing, placement, soldering, cleaning, and rework

- Equipment Technology – application of printers, placement machines, soldering, and inspection systems

- System Control and Management – production line configuration, process control, and quality management

These layers work together to form a comprehensive SMT framework, making it one of the most integrated fields in modern electronic manufacturing.

5. SMT Process Methods and Technical Categories

The SMT manufacturing process can be further broken down into several specialized techniques:

- Coating and dispensing: solder paste printing, adhesive dispensing, or transfer methods

- Placement: sequential placement, simultaneous placement, or inline placement systems

- Soldering: reflow soldering and wave soldering (single-wave or dual-wave)

- Cleaning: solvent cleaning, aqueous cleaning, or no-clean processes

- Rework: hot-air, infrared, or localized heating repair

- Inspection: a combination of contact and non-contact testing technologies

Together, these methods form the core operational chain of the SMT process.

6. Inspection and Quality Control

Inspection plays a crucial role throughout the SMT production line.

Common inspection methods include:

- AOI (Automated Optical Inspection) for general solder quality

- X-Ray inspection for hidden joints such as BGAs

- ICT (In-Circuit Test) for electrical continuity

- FCT (Functional Circuit Test) for full performance verification

A robust quality control system ensures consistent, reliable performance across every batch of PCBA assemblies.

Why SMT Technology Matters

A mature SMT ecosystem provides measurable benefits:

- Higher assembly density and integration

- Improved solder joint reliability

- Greater compatibility with full automation

- Superior long-term product stability

For this reason, the level of SMT process capability is a key indicator of a PCBA manufacturer’s technical competence.

Conclusion

Surface Mount Technology is not a single process—it is a complete engineering system that integrates component design, PCB manufacturing, assembly processes, materials, and equipment management.

Understanding SMT as a structured, interconnected discipline is the foundation for achieving reliable, high-quality PCBA production.