Introduction: Why Understanding the Difference Between Solder Paste and Flux Matters

Solder paste and flux are two essential materials in electronics manufacturing and repair, but they serve distinct functions and are not interchangeable. Confusing the two can lead to improper solder joints, reduced reliability, and process inefficiencies.

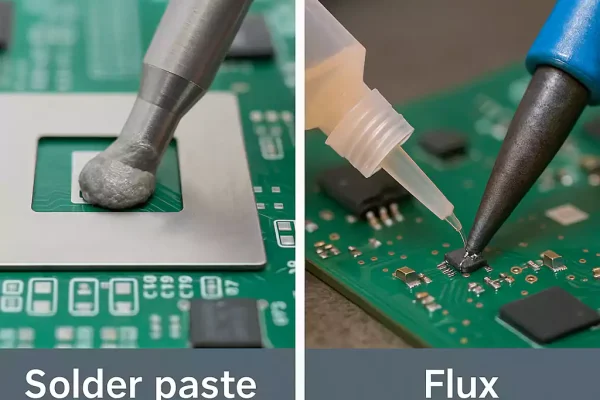

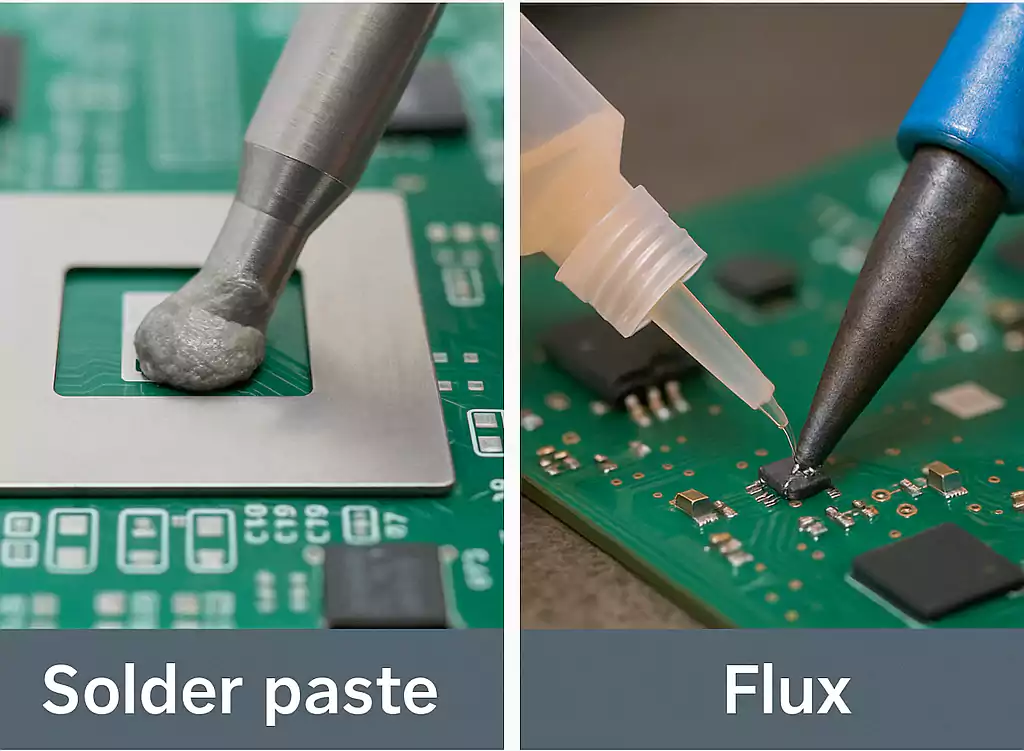

Solder paste is a mixture of powdered solder alloy and flux, primarily used in surface mount technology (SMT) for automated soldering processes. Flux, on the other hand, is a chemical agent designed to remove oxides and improve wetting during soldering, commonly used in hand-soldering, rework, and wave soldering.

Clear differentiation between solder paste and flux is critical for material selection, process control, and achieving consistent soldering quality. This article outlines their core differences, use cases, handling considerations, and common misconceptions—providing a comprehensive guide for optimizing soldering performance in any application.

Definition and Composition: What Are Solder Paste and Flux?

What Is Solder Paste?

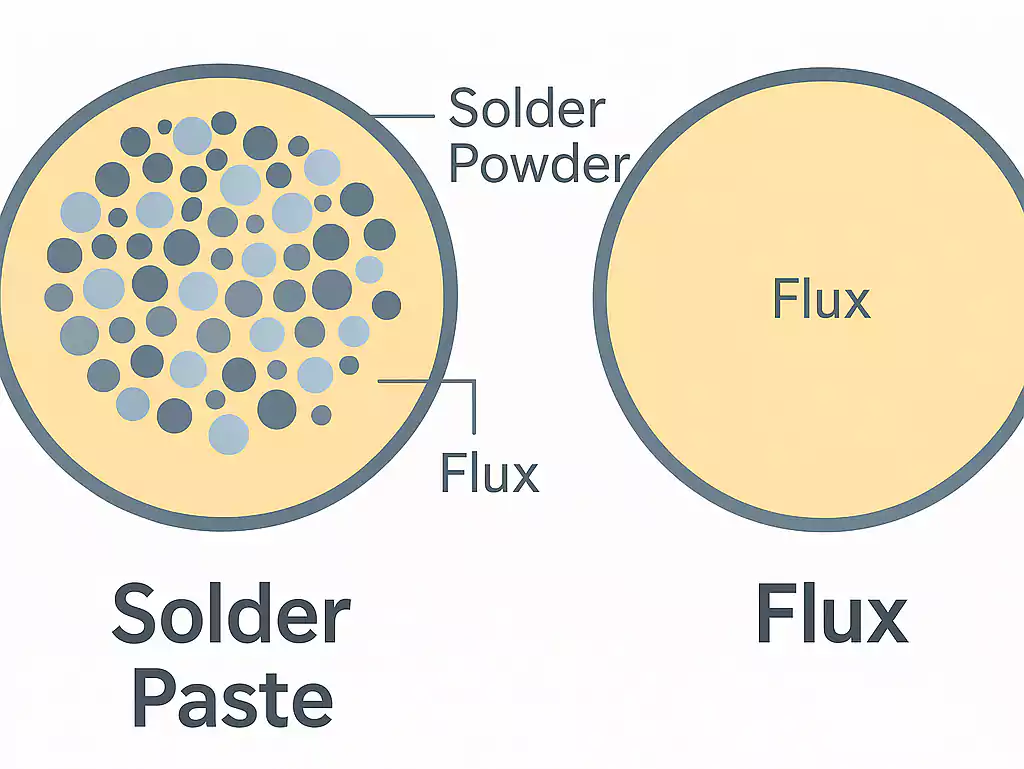

Solder paste is a gray, viscous material composed of solder alloy powder suspended in flux. It serves two primary functions in electronics assembly: delivering solder to the joint and facilitating proper wetting by cleaning the metal surfaces during reflow. The alloy particles are typically made of tin-based materials such as Sn63/Pb37 or lead-free alternatives like SAC305.

Solder paste is primarily used in Surface Mount Technology (SMT) processes. It is applied to printed circuit boards (PCBs) through stencil printing, then heated in a reflow oven to melt the alloy and form permanent electrical connections. The flux component within the paste helps remove oxides from component leads and pads, ensuring a reliable solder bond.

What Is Flux?

Flux is a chemical agent used to remove oxidation, prevent further oxide formation, and improve solder wetting during the soldering process. It does not contain any solder metal. Flux is available in various forms, including liquid, gel, and paste, and can be applied independently or integrated into solder wire or solder paste.

There are several types of flux, each suited for different applications:

- Rosin-based flux: Traditional and widely used, often requiring post-soldering cleaning.

- No-clean flux: Leaves minimal residue and typically does not require cleaning.

- Water-soluble flux: Easy to clean but highly active, often used in high-reliability assemblies.

Flux is commonly used in hand-soldering, rework, and wave soldering processes to improve solder flow and joint quality.

Key Difference in Composition

| Property | Solder Paste | Flux |

|---|---|---|

| Contains solder alloy | ✔ Yes | ✘ No |

| Contains flux | ✔ Yes (as a component) | ✔ Yes (100%) |

| Primary function | Deposit solder + clean during reflow | Clean surfaces, aid wetting |

| Common applications | SMT, reflow soldering | Hand-soldering, repair, wave |

| Physical form | Thick paste (powder + flux) | Liquid, gel, or standalone paste |

Understanding the composition of solder paste and flux is fundamental for selecting the correct material for specific soldering methods and ensuring process reliability. Misapplying one in place of the other can result in weak joints, poor wetting, or even complete process failure.

Function Comparison Overview: Solder Paste vs Flux

Solder paste and flux serve different roles in the soldering process. While both are essential to creating strong, reliable joints, they operate in distinct ways and are used at different stages and in different environments. The table below highlights their functional differences to help users select the correct material for their specific application.

Functional Comparison Table

| Criteria | Solder Paste | Flux |

|---|---|---|

| Main Composition | Metal solder powder + flux | Flux only (no solder alloy) |

| Primary Function | Delivers solder and facilitates bonding during reflow | Removes oxidation and enhances wetting |

| Application Type | Automatic or semi-automatic (SMT, stencil printing) | Manual or selective (rework, repair, wave soldering) |

| Solder Supply | ✔ Yes – provides solder alloy | ✘ No – does not provide solder |

| Flux Inclusion | ✔ Yes – built-in flux | ✔ Yes – standalone flux |

| Common Use Cases | Surface mount assembly, PCB reflow soldering | Hand soldering, through-hole soldering, cleaning prep |

| Application Method | Applied using stencil, syringe, or jet dispenser | Brushed, dispensed, pen-applied, or sprayed |

| Residue Management | Depends on flux type (no-clean, water-washable, rosin) | Depends on type; may require post-solder cleaning |

| Thermal Behavior | Melts during reflow; solidifies to form joints | Remains active during heating; does not form physical bond |

| Shelf Life & Storage | Shorter; refrigeration often required | Longer; stable at room temperature |

| Process Integration | Critical for automated SMT assembly | Critical for manual soldering and component prep |

| Cleaning Required? | Optional (depends on flux formulation) |

Usage Guide: When to Use Solder Paste or Flux

Choosing between solder paste and flux depends on the soldering method, application environment, and type of components involved. Using the correct material ensures strong electrical connections, minimal defects, and an efficient workflow.

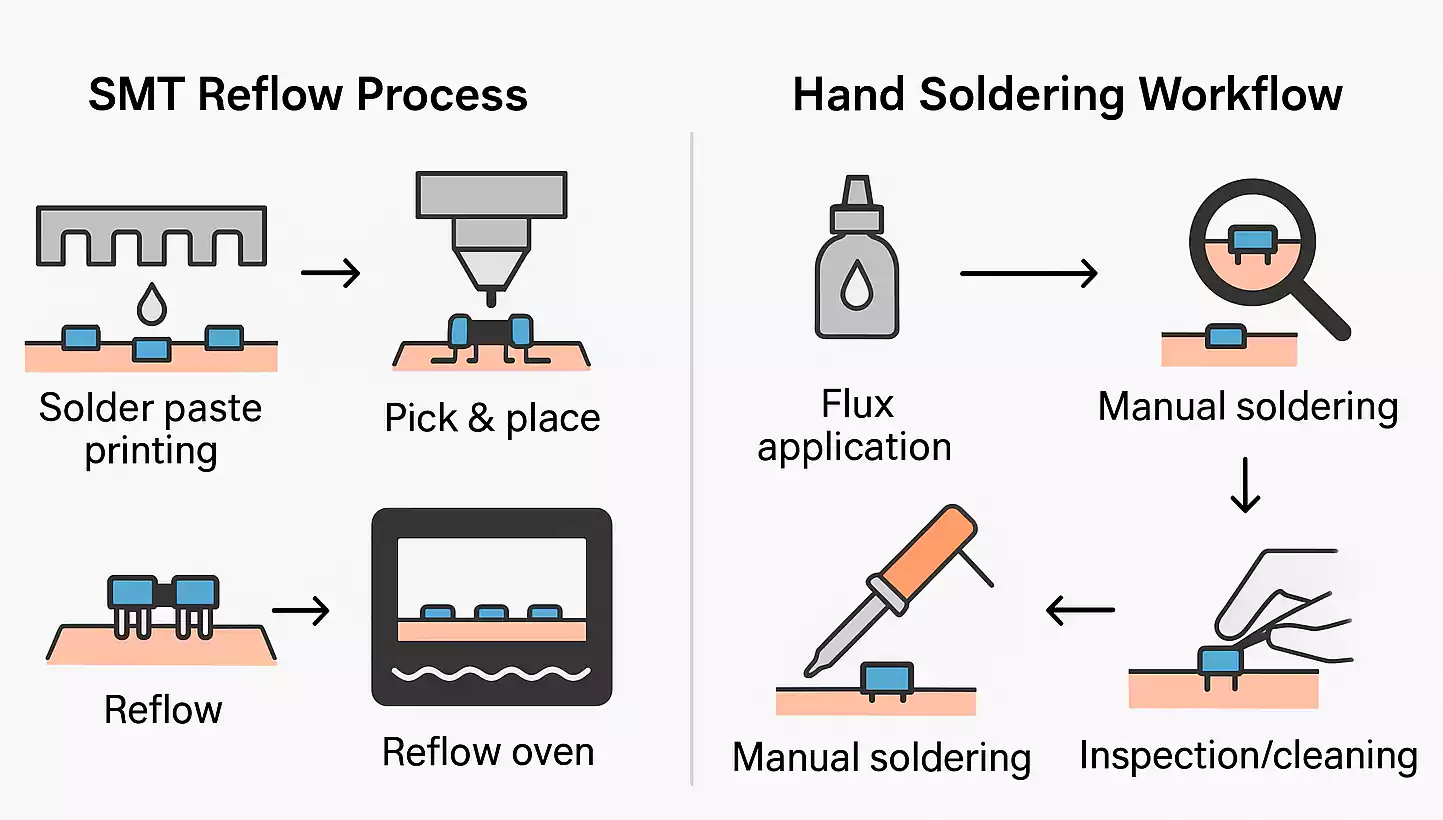

When to Use Solder Paste

Solder paste is best suited for automated or semi-automated processes, especially where precision and repeatability are required. Use solder paste in the following scenarios:

- Surface Mount Technology (SMT):

Solder paste is essential for placing surface-mount components on PCBs. It is applied via stencil printing and reflowed in an oven to form joints. - Reflow Soldering:

In reflow ovens, solder paste melts, flows, and solidifies to create clean, uniform solder joints. - Small-Batch or Prototype PCB Assembly:

Engineers and hobbyists often use solder paste with a hot air gun or toaster oven for small-scale SMT projects. - Precise Solder Volume Control:

Because it combines alloy and flux, solder paste ensures the right amount of solder is delivered with each application.

When to Use Flux

Flux is typically used in manual soldering, repair work, or through-hole soldering, where solder is already available (e.g., via solder wire or pre-tinned pads). Use flux in these situations:

- Hand Soldering and Touch-Up Work:

Flux improves wetting, especially when using solid-core or flux-cored solder wire. It ensures better adhesion and smoother flow. - Rework and Component Replacement:

When desoldering or replacing components, applying fresh flux helps reflow existing solder and reduce oxidation. - Through-Hole Soldering / Wave Soldering:

In large-scale assembly lines, flux is applied to PCB pads and pins to promote wetting before passing through a solder wave. - Oxidation Removal and Surface Preparation:

Flux is useful for prepping oxidized pads, wires, or connectors to restore solderability.

Summary Table: Choosing the Right Material

| Scenario | Recommended Material |

|---|---|

| Surface mount component placement (SMT) | Solder Paste |

| Reflow soldering in oven or hot air gun | Solder Paste |

| Hand soldering with solder wire | Flux |

| Repair or rework of solder joints | Flux |

| Through-hole component soldering | Flux |

| PCB prototyping or stencil printing | Solder Paste |

| Cleaning or reactivating oxidized surfaces | Flux |

Best Practices and Common Mistakes in Using Solder Paste and Flux

Using solder paste and flux correctly is essential for achieving reliable, defect-free solder joints.This section outlines proven best practices along with common pitfalls to avoid.

Solder Paste: Best Practices

- Store Properly

Keep solder paste refrigerated (typically 0–10 °C / 32–50 °F) and sealed to prevent oxidation and degradation. Let it return to room temperature before use to avoid condensation. - Use Within Shelf Life

Expired solder paste may separate or lose printability, leading to poor solder volume control or voids. Always check manufacturing and expiration dates. - Print with the Right Stencil

Use a high-quality stainless steel stencil and appropriate aperture design to ensure consistent deposition. Maintain stencil cleanliness to prevent bridging or clogging. - Apply Controlled Volume

Avoid excessive solder paste application. Too much paste can cause bridging, tombstoning, or solder balls during reflow. - Follow Proper Reflow Profile

Use the recommended temperature curve for the specific solder paste alloy (e.g., SAC305). Incorrect heating can result in cold joints, voids, or component damage. - Avoid Double Reflow Without Precautions

If multiple reflow cycles are needed, ensure additional flux is applied or paste is refreshed to prevent oxidation and incomplete wetting.

Solder Paste: Common Mistakes

- Skipping paste warming time: Using cold paste directly from refrigeration can cause moisture contamination.

- Reusing expired paste: Leads to inconsistent joint quality.

- Applying paste in uncontrolled environments: High humidity and temperature variations can affect consistency.

- Applying paste on dirty or oxidized pads: Reduces bonding strength.

Flux: Best Practices

- Use the Right Type of Flux

Rosin-based flux offers strong activity but typically requires post-solder cleaning. No-clean flux leaves minimal residue and is ideal for dense or compact boards. Water-soluble flux is highly active and easy to clean, making it suitable for high-reliability applications. - Apply Sparingly and Precisely

Use brushes, flux pens, or precision dispensers to avoid excessive application, which can leave conductive or corrosive residues. - Clean If Required

Always follow manufacturer recommendations for post-solder cleaning. Water-soluble and rosin-based flux typically require washing to avoid long-term reliability issues. - Store in Sealed Containers

Prevent exposure to air and moisture to maintain flux effectiveness. - Use Fresh Flux for Rework

When desoldering or repairing joints, always add fresh flux to improve heat transfer and wetting.

Flux: Common Mistakes

- Using too much flux: Causes sticky residues and may require extensive cleaning.

- Assuming no-clean flux never needs cleaning: In high-frequency or mission-critical circuits, even no-clean flux may leave unwanted residues.

- Applying flux on contaminated surfaces: Dirt or oil on the PCB can neutralize flux activity.

- Using incorrect flux for lead-free alloys: Not all fluxes are optimized for high-temperature lead-free soldering.

Shelf Life and Storage Recommendations: Solder Paste vs Flux

Proper storage and handling of solder paste and flux are critical to maintaining their performance and reliability. Both materials degrade over time, but solder paste is particularly sensitive to environmental conditions due to its complex composition.

Solder Paste: Shelf Life & Storage Guidelines

Solder paste typically contains fine metal powder suspended in a flux medium, making it chemically and physically unstable over time. Poor storage can lead to separation, drying, oxidation, or loss of printing and reflow characteristics.

Typical Shelf Life

- Refrigerated (0–10 °C / 32–50 °F):

~3 to 6 months (check manufacturer’s datasheet) - Room Temperature (Not recommended):

May degrade in days to weeks, depending on formulation

Best Storage Practices

- Keep Refrigerated: Store solder paste in a sealed container inside a fridge dedicated to electronics materials (not food).

- Avoid Freezing: Freezing can alter viscosity and particle distribution.

- Let It Reach Room Temperature Before Use: Remove paste at least 4 hours before use to prevent moisture condensation.

- Use FIFO (First In, First Out): Rotate stock to use older material first.

Flux: Shelf Life & Storage Guidelines

Flux is generally more stable than solder paste but still susceptible to environmental degradation—especially when exposed to air or moisture.

Typical Shelf Life

- Rosin-Based Flux: 12 to 24 months

- No-Clean Flux: Up to 12 months

- Water-Soluble Flux: Shorter lifespan; typically 6 to 12 months

Best Storage Practices

- Seal Tightly After Use: Prevent solvent evaporation and contamination.

- Store at Room Temperature: Ideal range: 18–25 °C (64–77 °F)

- Keep Away from UV Light and Heat: Both can degrade active agents.

- Avoid Cross-Contamination: Use clean tools or dispensers to apply flux.

Comparison Table: Shelf Life and Storage

| Property | Solder Paste | Flux |

|---|---|---|

| Contains Metal Alloy | ✔ Yes | ✘ No |

| Sensitivity to Temperature | High – requires refrigeration | Moderate – store at room temperature |

| Shelf Life (Typical) | 3–6 months (refrigerated) | 6–24 months (depending on type) |

| Needs Moisture Control | ✔ Yes – condensation risk | ✔ Yes – keep sealed |

| Affected by Light Exposure | ✘ Minimal | ✔ Yes – especially liquid flux |

| Stability Over Time | Low – degrades faster | Higher – but still time-sensitive |

| Reusable After Expiry? | ✘ No – discard | ✘ Not recommended |

Frequently Asked Questions (FAQ)

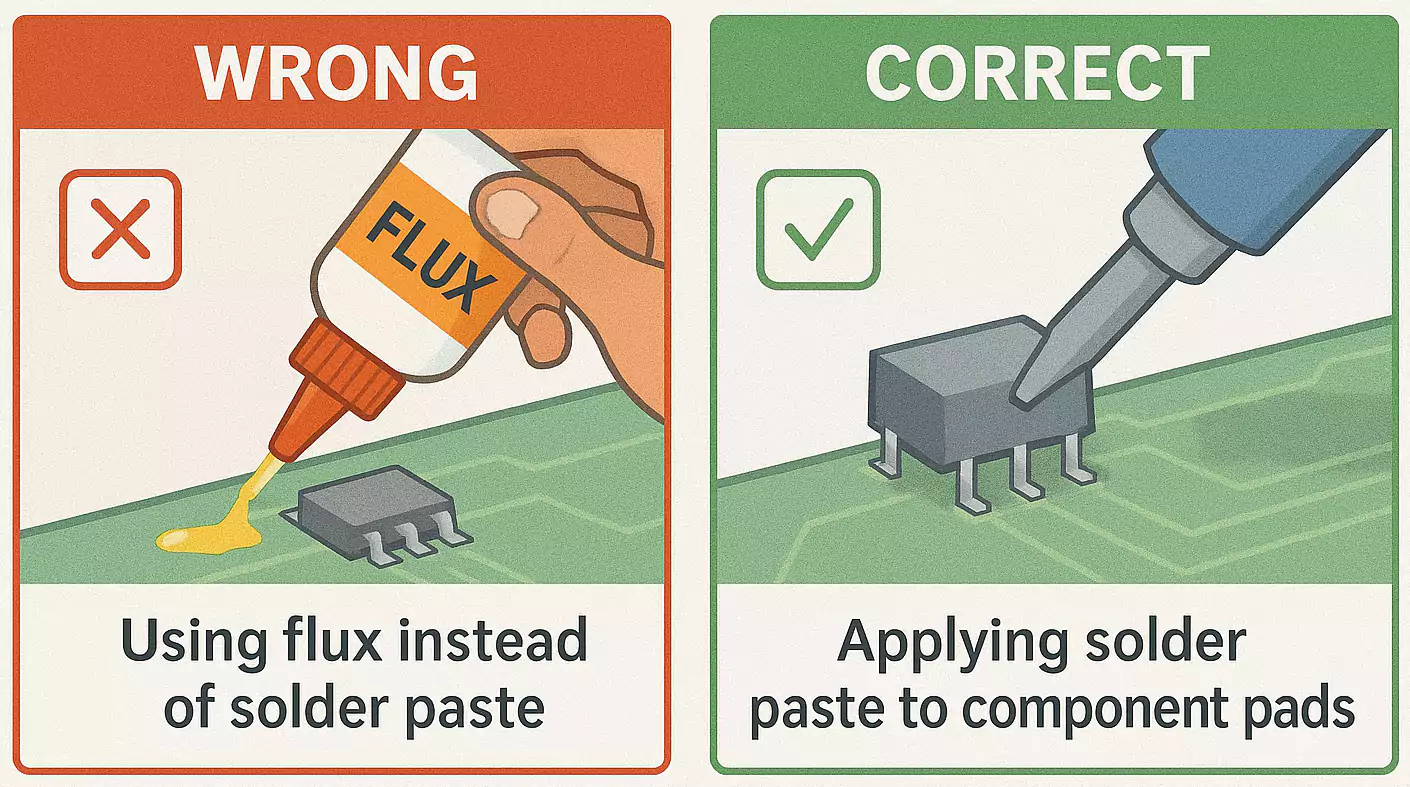

Can I use flux instead of solder paste?

No. Flux alone does not contain any solder alloy and cannot form a mechanical or electrical joint by itself. Solder paste includes both solder metal and flux, making it suitable for reflow and SMT processes. Flux is only intended to clean and prepare surfaces, not to provide solder material.

Can solder paste be used for hand soldering?

Technically yes, but it's not ideal. Solder paste is designed for stencil printing and reflow soldering. For hand soldering, flux-cored solder wire is preferred for better control, cleanliness, and ease of use. However, in some fine-pitch rework scenarios, paste may be applied using a syringe and reflowed with hot air.

Do I need to clean off flux after soldering?

It depends on the flux type:

•Rosin-based and water-soluble flux: Usually require cleaning to prevent corrosion or conductivity issues.

•No-clean flux: Leaves minimal residue and is generally safe to leave in place unless used in high-reliability or sensitive circuits (e.g., RF, aerospace).

Does solder paste expire?

Yes. Solder paste has a limited shelf life (typically 3 to 6 months when refrigerated). After expiry, it can separate, dry out, or degrade—leading to poor print definition, solder balling, or weak joints. Always check the manufacturer’s label and storage guidelines.

What happens if I apply too much flux?

Excess flux can leave sticky, corrosive, or conductive residues, especially if it's not no-clean. It may also lead to solder bridging or inconsistent wetting. Apply flux sparingly and clean thoroughly if required.

Can I add flux to expired solder paste to restore it?

No. Adding fresh flux will not restore the physical or chemical integrity of expired solder paste. The metal particles may have oxidized or separated, and viscosity may be inconsistent. Always discard expired solder paste.

Is solder paste the same as flux-cored solder wire?

No. Solder paste is a semi-solid mixture used primarily in reflow and SMT applications. Flux-cored solder wire is a solid metal wire with flux embedded inside, designed for manual soldering. Each is intended for different processes and tools.

Do I need to use flux if I'm using flux-cored solder wire?

Not always. Flux-cored wire includes internal flux, which is sufficient for most standard joints. However, in challenging conditions (e.g., oxidized surfaces, fine-pitch components), applying additional flux can improve wetting and solder flow.

How do I know which flux type to use?

Choose based on your process:

•Rosin-based: Stronger cleaning, but requires post-solder cleaning.

•No-clean: Minimal residue; ideal for compact boards or consumer electronics.

•Water-soluble: Best for critical applications, but requires thorough rinsing.

Can I use both solder paste and flux together?

Yes, but only when necessary. In some advanced rework or double-reflow scenarios, extra flux may be added to pre-applied solder paste to enhance wetting. However, adding too much can lead to residue or bridging issues.

Conclusion

Understanding the difference between solder paste and flux is essential for selecting the right material and ensuring successful soldering outcomes. Solder paste combines solder alloy and flux in a paste form, making it ideal for SMT assembly and reflow soldering. In contrast, flux is a chemical cleaning agent used to improve wetting and joint reliability during manual soldering, rework, or wave soldering.

Choosing the correct material based on the application—whether automated PCB production or hand soldering repairs—can significantly reduce soldering defects and improve long-term circuit performance. Proper storage, handling, and cleaning practices are equally important to maintain material integrity and process consistency.