Introduction

Solder paste is a critical material in surface mount technology (SMT), used to attach electronic components to printed circuit boards (PCBs). It is a mixture of powdered solder and flux that enables precise, reliable soldering—especially during reflow processes.

But what exactly is solder paste? How does it compare to traditional solder wire or flux? And when should you use it during PCB assembly?

This guide covers the basics of solder paste—what it is, how it’s used in both manual and automated soldering, the differences between solder paste and flux, and how to choose the right type.

What Is Solder Paste?

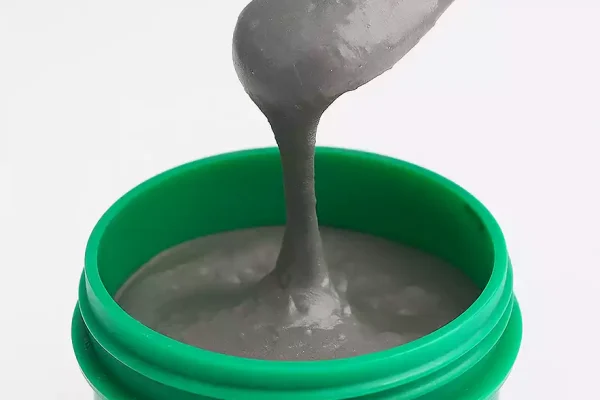

Solder paste is a gray, sticky mixture composed of tiny metal solder particles suspended in a specialized flux medium. It is the material that makes modern surface mount technology (SMT) soldering possible. When applied to the copper pads of a printed circuit board (PCB), solder paste temporarily holds components in place before heat is applied during the reflow soldering process.

When heated, the solder particles melt and form strong electrical and mechanical connections between component leads and PCB pads. The flux within the paste removes oxides from metal surfaces, improving wetting and ensuring a clean bond.

Unlike solder wire, which is used for hand soldering, or flux, which only cleans and prepares surfaces, solder paste contains both the solder alloy and the flux. This dual function makes it ideal for automated PCB assembly and precise, high-density component placement.

Solder Paste vs. Flux vs. Solder Wire

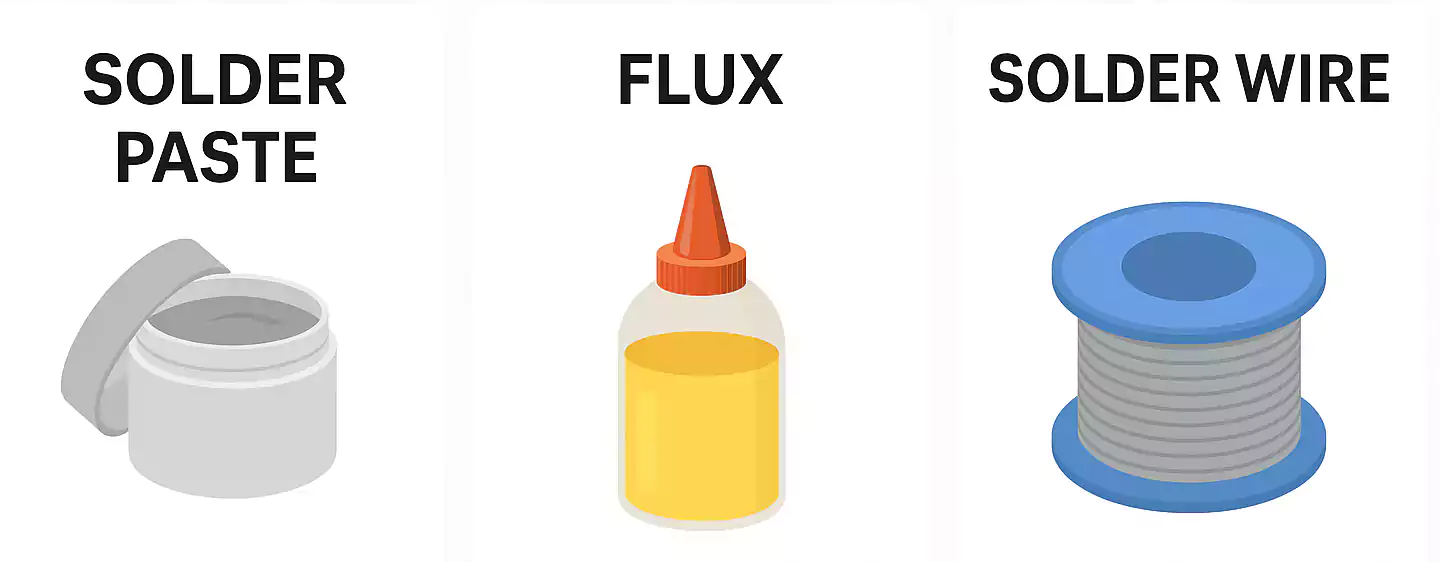

If you're new to soldering, it's easy to confuse solder paste, flux, and solder wire—but each plays a different role in the assembly process.

1.Solder Paste

Solder paste is a thick, gray material made from powdered solder alloy mixed with flux. It is specifically designed for surface mount technology (SMT) applications, where it is applied to PCB pads before component placement and reflow soldering. Solder paste provides both the solder and the flux in one step, making it ideal for high-speed or high-precision assembly.

2.Flux

Flux is a chemical cleaning agent that removes oxides from metal surfaces during soldering. It improves wetting, prevents oxidation, and helps solder flow properly. However, flux alone does not create electrical connections—it must be used in conjunction with a solder alloy such as paste or wire.

3.Solder Wire

Solder wire is a solid form of solder, often with a flux core, used mainly for manual soldering with a soldering iron. It melts when heated to join metal surfaces together and is commonly used in prototyping, repair, or through-hole assembly.

| Material | Contains Flux | Contains Solder | Best Use Case |

|---|---|---|---|

| Solder Paste | Yes | ✅ Yes | SMT and reflow soldering |

| Flux Only | Yes | ❌ No | Cleaning and prepping surfaces |

| Solder Wire | (Core) | ✅ Yes | Hand soldering, repair work |

Key takeaway:

- Use solder paste for automated SMT and reflow.

- Use solder wire for manual soldering.

- Use flux as a support material when solder isn’t flowing properly.

How to Use Solder Paste

Applying solder paste correctly is key to achieving strong and reliable solder joints—especially in SMT (Surface Mount Technology) assembly. There are two main techniques used to apply solder paste:

1. Apply the Solder Paste

Solder paste is typically applied to the PCB using one of the following methods:

- Stencil Printing (for production)

This is the most common method used in automated PCB assembly. A metal stencil with cutouts matching the pad layout is placed over the board. Solder paste is spread across the stencil using a squeegee, depositing a precise amount of paste onto each pad.

- Dispensing (for prototyping or small batches)

Dispensing involves using a syringe or automated dispenser to apply solder paste directly onto the PCB. It’s often used for low-volume builds, repairs, or boards with irregular pad shapes.

2. Place the Components

Once the paste is applied, surface-mount components (SMDs) are placed on top. The tackiness of the paste temporarily holds them in place. This can be done:

- Automatically using a pick-and-place machine.

- Manually using tweezers for low-volume or prototype work.

3. Reflow the PCB

After placement, the board is heated in a reflow oven (or with a hot air tool for manual work). As the temperature rises:

- The flux activates and removes oxidation.

- The solder particles melt and flow.

- Strong, electrically conductive joints form as the solder cools.

Reflow temperature profiles vary depending on the paste type, but typical peak temperatures range from 230°C to 250°C for lead-free solder.

How to Choose the Right Solder Paste

1. Lead-Free vs Leaded

Lead-free (e.g., SAC305) is standard for RoHS-compliant electronics.

Leaded (e.g., Sn63/Pb37) is still used in some specialized or legacy applications.

2. Flux Type

No-clean: Leaves little residue—no cleaning needed.

Water-soluble: Requires cleaning—used for high-reliability products.

3. Powder Type (Particle Size)

Type 3: General use.

Type 4/5: For fine-pitch components (like 0.4 mm BGA).

4. Storage

Keep refrigerated (0–10 °C).

Let it return to room temperature before use.

Use within shelf life (typically 6–12 months)

Frequently Asked Questions (FAQs)

How can I tell if “solder paste” is really just flux?

Some low-cost products are mislabeled online. True solder paste always contains a metal alloy (like Sn63/Pb37 or SAC305) mixed with flux—it looks gray or metallic. Flux alone is usually clear, amber, or brown and contains no solder metal. Always check the specs: if there's no alloy listed, it's not solder paste.

Can I use only flux for reflow soldering?

No. Flux cleans surfaces but doesn’t provide solder. For reflow soldering, solder paste is required because it contains both the flux and the metal alloy needed to form strong electrical connections.

What are the different types of flux, and when should I use each?

·Liquid flux – Best for wave soldering or large areas.

·Flux pens – Ideal for rework and small touch-ups.

·Gel/paste flux – Stays in place; great for hand soldering SMDs or BGA reballing.

·No-clean flux – Leaves minimal residue; useful when cleaning isn't practical.

Why does solder paste expire, and how do I store it?

Solder paste separates or dries out over time. Heat and moisture speed up the process.

To extend shelf life:

·Store at 0–10 °C in a sealed container.

·Let it warm to room temperature before use.

·Stir gently before printing.

·Expired paste can cause poor print quality and weak solder joints.

Can I use plumbing or industrial flux on electronics?

Absolutely not. Plumbing flux is highly acidic and will corrode PCB pads, leave conductive residues, and damage components. Always use flux or solder paste made for electronics, which are non-corrosive and IPC-compliant.

Does solder paste contain flux?

Yes. Solder paste is a combination of powdered solder alloy and flux. The flux cleans the metal surfaces, while the solder alloy melts to form joints. Without flux, the solder wouldn’t bond properly.

Conclusion

Solder paste is essential in modern PCB assembly, particularly for surface mount technology (SMT). By combining flux and solder alloy in a single material, it enables precise and reliable solder joints during reflow soldering.

Knowing how solder paste works—and how it differs from flux or solder wire—helps prevent common issues like bridging, poor wetting, and weak joints. Whether you're hand-soldering a prototype or managing high-volume SMT production, choosing the right solder paste enhances both efficiency and build quality.