Industrial control boards are the core components of automation systems, acting as the "brain" of industrial equipment. Their performance and reliability are critical to overall system stability. The Surface Mount Technology (SMT) process used in manufacturing these boards demands high precision and stringent quality control. This article explores the essential SMT process requirements for industrial control boards across every production stage.

Component Preparation and Quality Screening

Before the SMT assembly begins, all electronic components must undergo strict inspections to verify model specifications, functionality, and compliance with quality standards. Components should also be cleaned and dried to prevent issues like poor soldering due to dust or moisture.

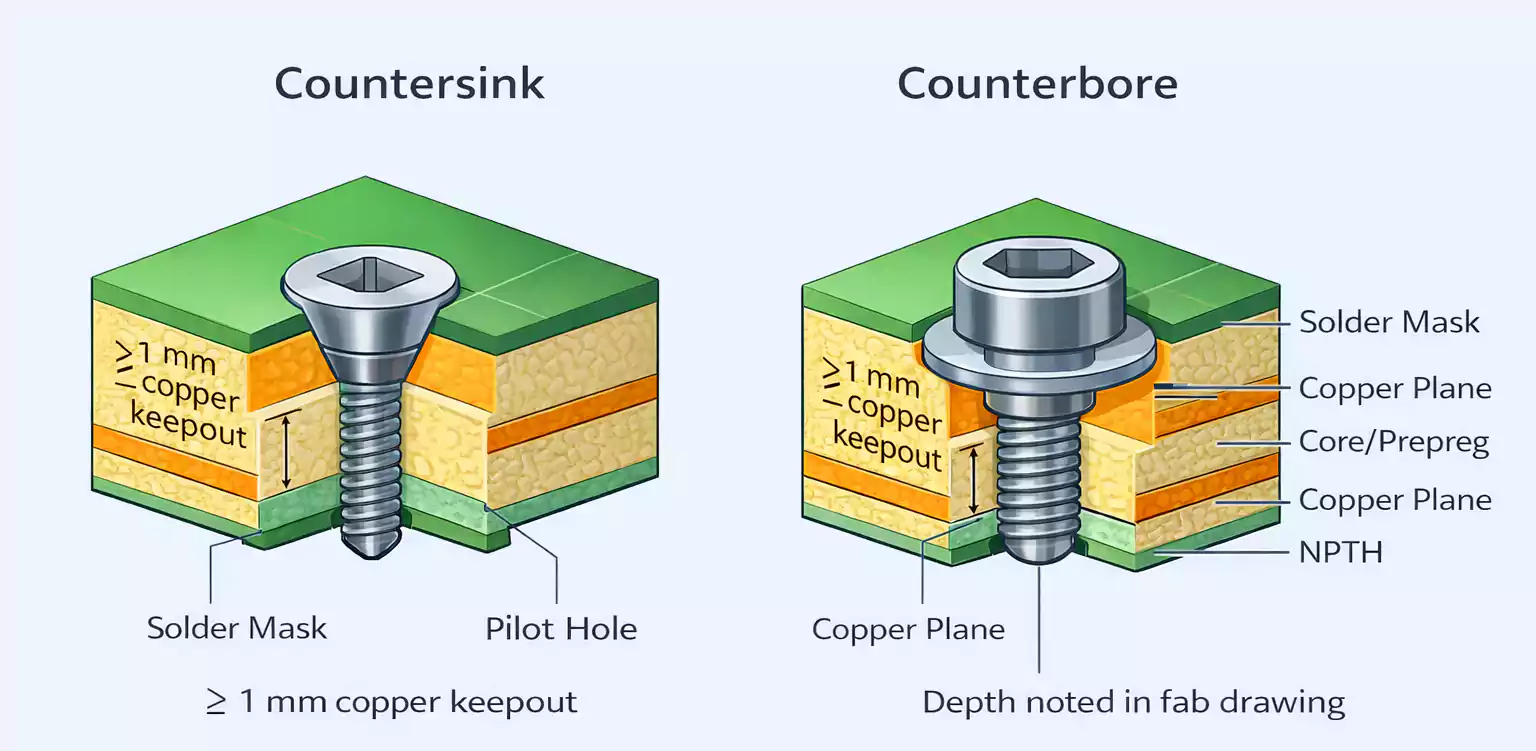

PCB Printing and Solder Paste Application

The first step in SMT is creating the printed circuit board (PCB) by transferring the circuit design onto the board using photolithography. Afterward, solder paste is applied precisely to the solder pads using a stencil. This stage demands precise control over paste thickness, viscosity, and alignment for optimal soldering quality.

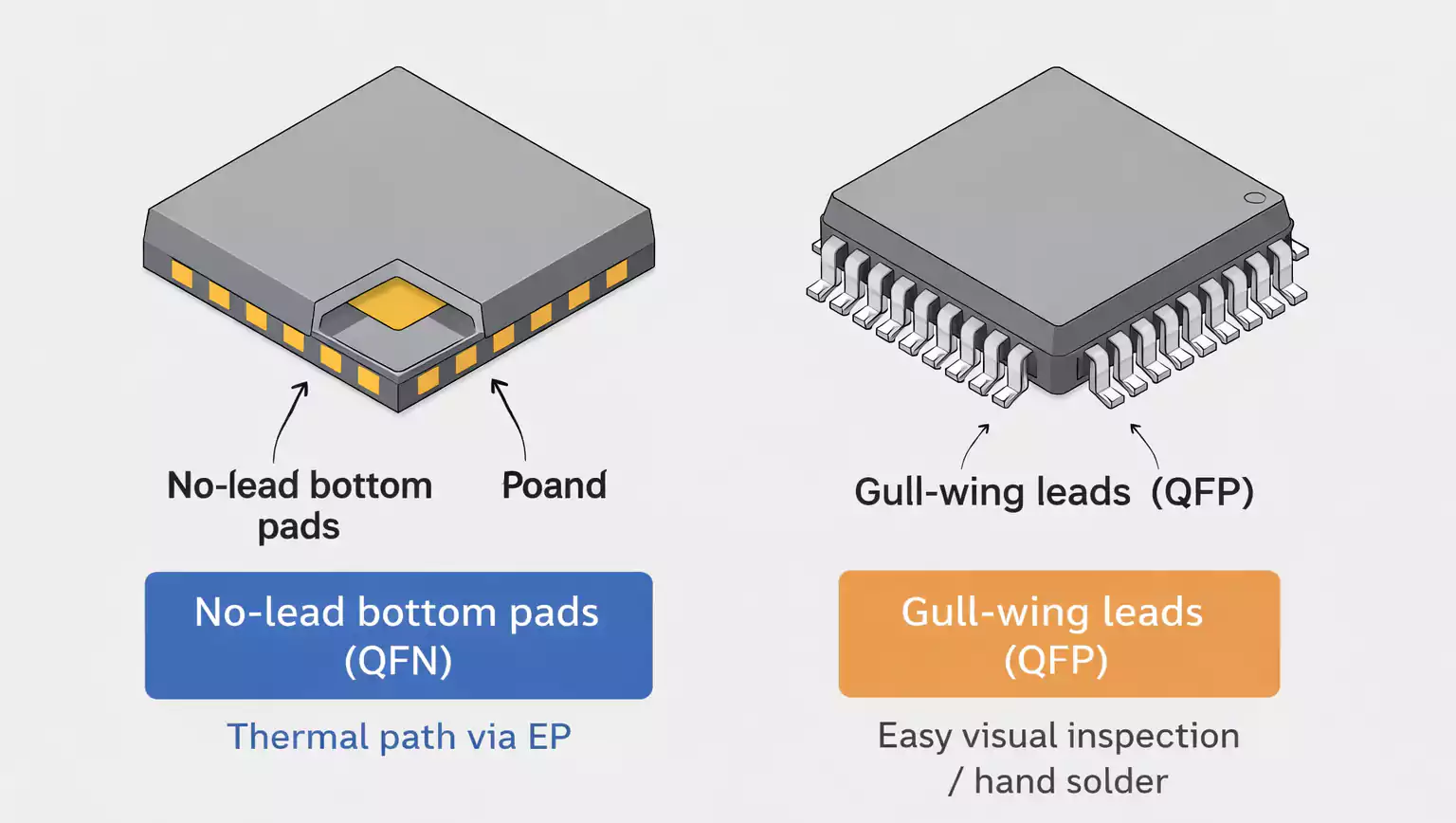

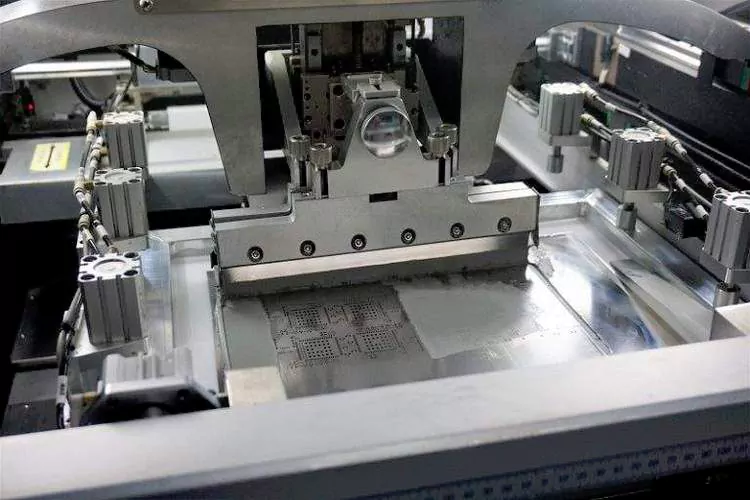

High-Precision Automatic Component Placement

Component mounting is one of the most critical SMT steps. High-speed automated pick-and-place machines are used to position surface-mount devices (SMDs) on the PCB with extreme accuracy. The placement quality directly affects solder joint reliability and overall board performance.

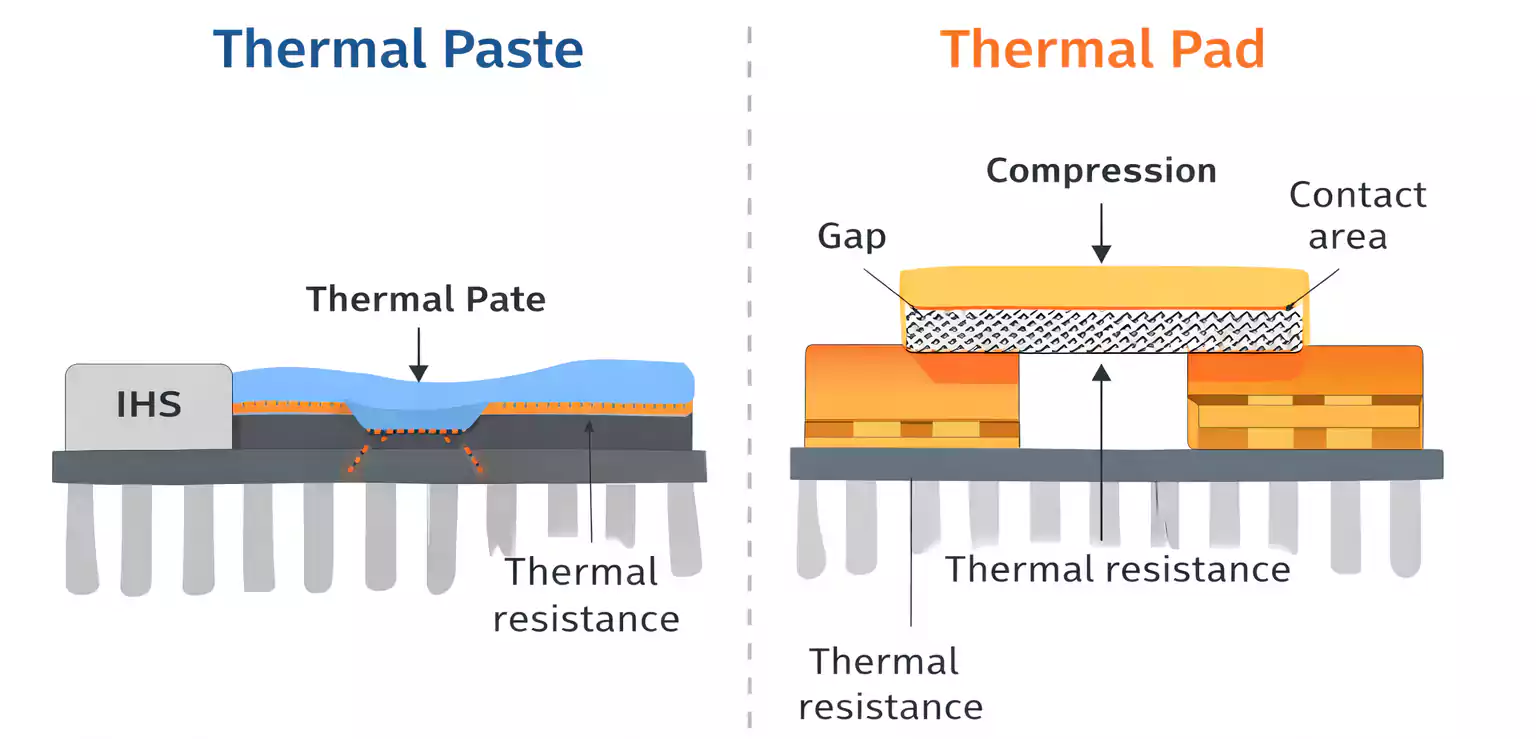

Strictly Controlled Reflow Soldering Process

After placement, the PCB goes through reflow soldering, where it is heated in a reflow oven to melt the solder paste and form strong solder joints. Proper temperature profiling and timing are vital to prevent damage to components or the PCB itself.

Comprehensive Quality Inspection and Testing

To ensure product reliability, each soldered PCB undergoes multiple inspection processes, including AOI (Automated Optical Inspection) and X-ray inspection, to detect misalignments, cold joints, or short circuits. Functional testing (FCT) is also conducted to verify the electrical performance of the board.

Post-Processing and Protective Packaging

Boards that pass all inspections go through additional steps like cleaning, applying conformal coating (protective paint), and anti-static packaging. These post-processing treatments improve resistance to dust, moisture, and corrosion, ensuring durability during shipping and long-term operation.