Introduction

In modern electronics manufacturing, SMT pick-and-place machines do the heavy lifting—literally. They’re the core of any SMT (Surface Mount Technology) line, placing tiny surface-mount components onto circuit boards quickly and accurately.

But not all pick-and-place machines are built the same. Depending on your production needs—whether you're building prototypes, handling small batches, or running high-volume lines—there are different types of machines designed to get the job done right.

In this guide, we’ll break down the main types of SMT pick-and-place machines, what makes each one unique, and how to choose the best fit for your production goals.

Classification of Pick-and-Place Machines

Choosing the right SMT pick-and-place machine starts with knowing the main types out there. They’re typically categorized by automation level, placement method, mechanical design, and performance range.

1. By Automation Level

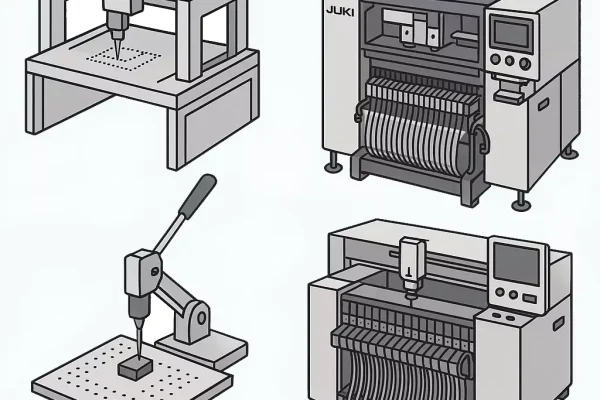

Manual Pick-and-Place Machines

Manual machines require human operators to place components onto the PCB using mechanical arms or tweezers with visual assistance. They are the most affordable option and are primarily used in:

- Prototyping and R&D

- Low-volume production

- Educational settings

Semi-Automatic Pick-and-Place Machines

These machines combine manual feeding or PCB loading with automated placement mechanisms. They often include:

- Component feeders

- Vision alignment systems

- Semi-automated pick-up arms

Fully Automatic Pick-and-Place Machines

Fully automated machines handle everything—from component picking to alignment, placement, and board handling. These are the standard in modern SMT lines.

Best for: High-volume production environments, such as consumer electronics, automotive, and telecom PCBs.

2. By Placement Method

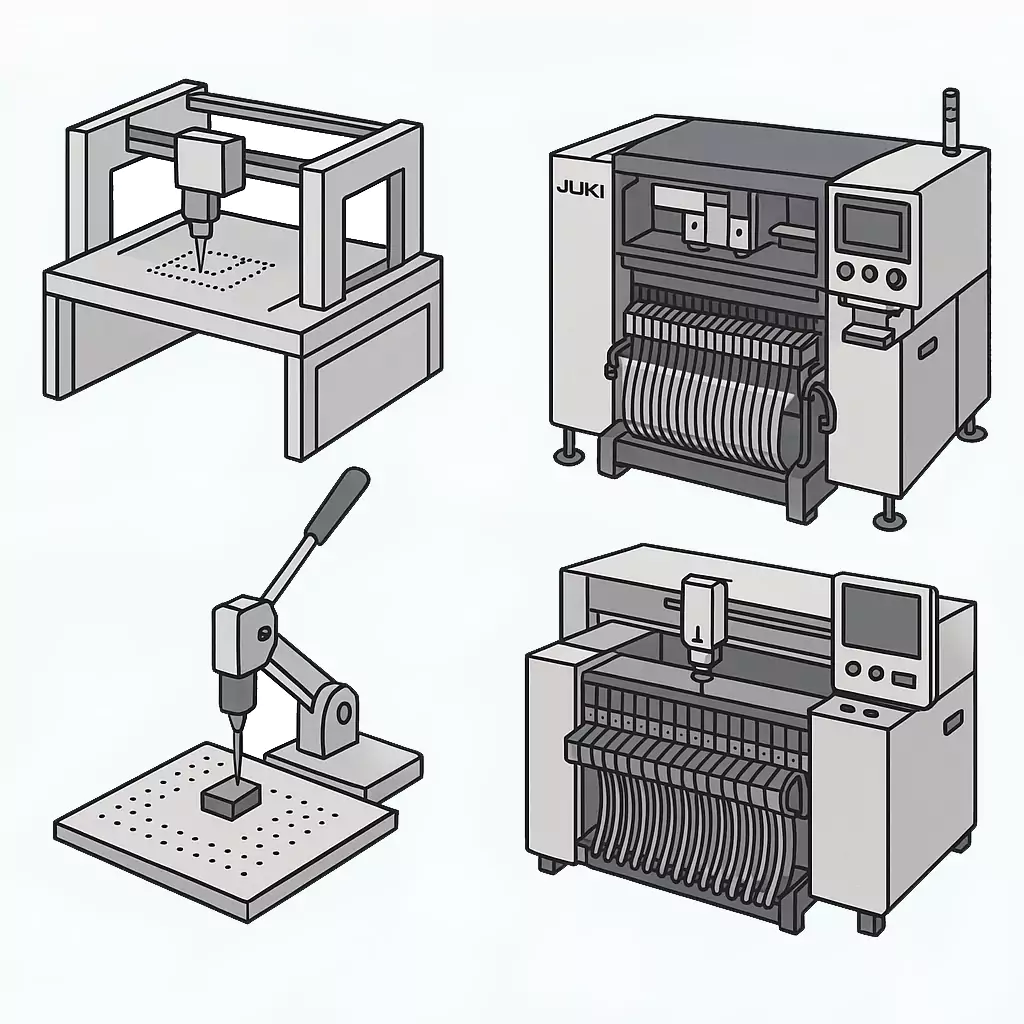

Sequential Placement

Sequential machines use one or more heads that move along X and Y axes to place components one at a time. While they offer high precision and are great for complex or varied component layouts, their slower speed makes them less efficient for large-scale production.

Simultaneous Placement

Simultaneous machines are equipped with multiple heads that work in parallel, placing several components in a single pass. This setup significantly boosts speed for repetitive tasks but lacks the flexibility needed for diverse or intricate designs.

Inline (Flow-Type) Placement

Also known as conveyor-type systems, inline machines operate as part of a continuous production line where boards are automatically transported between placement stages. They’re ideal for high-volume, nonstop manufacturing, though they require more upfront investment and well-structured planning.

Hybrid (Sequential + Simultaneous)

Hybrid machines combine the accuracy of sequential systems with the speed advantage of simultaneous placement. They strike a balance between performance and flexibility, making them well-suited for mid-to-high volume production with varied product mixes.

3. By Mechanical Structure

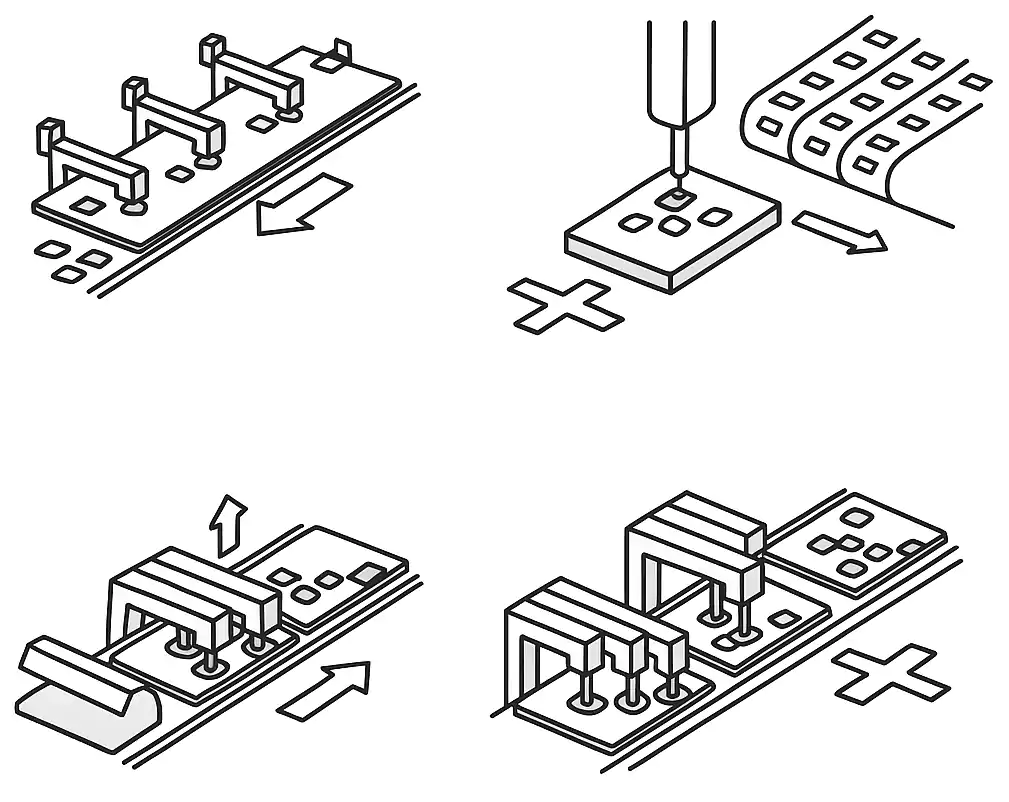

Gantry (X-Y Arm) Type

The gantry structure includes linear X and Y motion axes that move the placement head across a stationary PCB.

Benefits:

- Simple architecture

- Easily supports modular or scalable designs

- Cost-effective for medium-speed applications

Limitations:

- Speed is lower compared to rotary systems

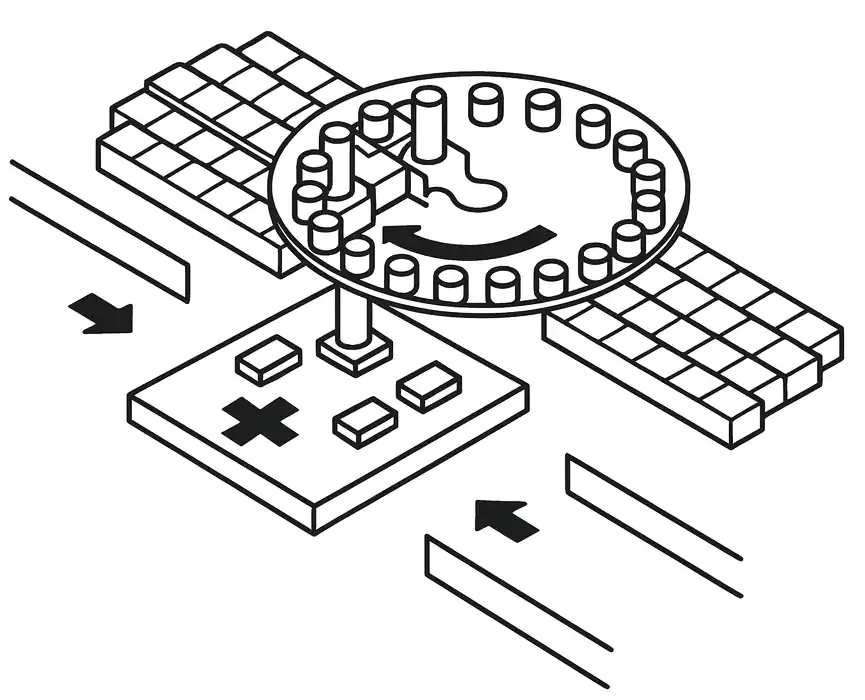

Rotary (Turret) Type

Rotary-type machines use a rotating turret head with multiple nozzles that pick and place components in a circular motion, often with a stationary PCB or small movement.

Benefits:

- Very high-speed placement

- Ideal for small, lightweight components (e.g., 0201, 0402)

Limitations:

- Less suitable for large or odd-shaped parts

- More complex mechanical systems

Modular Type

Modular systems are made of independent placement units that can be configured or expanded based on production requirements.

Benefits:

- Highly flexible and scalable

- Supports high mix, low volume (HMLV) production

- Easy maintenance and upgrades

Limitations:

- Higher initial cost

- Requires more advanced line integration

4. By Performance Tier

Medium-Speed Machines

These machines typically run below 20,000 CPH and offer a cost-effective solution for general-purpose production. They’re well-suited for small manufacturers but may fall short in high-volume environments.

High-Speed Machines

Operating at 30,000 CPH or more, high-speed models are optimized for mass production with fast feeders and advanced vision. They deliver excellent throughput but are less flexible and more expensive.

Multi-Function Machines

Designed for a wide range of components—including BGAs, QFPs, and odd-shaped parts—these machines are ideal for mixed-product lines. They offer high versatility but tend to be slower and costlier than speed-focused systems.

Key Selection Criteria for Choosing a SMT Pick-and-Place Machine

1. Placement Speed (CPH)

CPH (Components Per Hour) measures how many components a machine can place in one hour under ideal conditions.

- High-speed machines (>30,000 CPH) are ideal for large-scale production.

- Mid-range machines are better suited for flexible, small to medium batch runs.

2. Placement Accuracy

Precision is especially critical when working with fine-pitch components (e.g., 0201, 01005, BGA, QFN).

- Look for high-resolution vision systems and closed-loop control.

- Tolerance ranges like ±0.05 mm or better are preferred for high-density PCBs.

3. Component Compatibility

Ensure the machine can handle the full range of components you plan to use:

- Passive components: resistors, capacitors (0201 and smaller).

- Active ICs: QFP, BGA, CSP, etc.

- Odd-shaped components: connectors, coils, large or tall components.

Choose multi-function machines or modular platforms for flexibility across multiple component types.

4. PCB Size and Handling Capabilities

Consider the machine’s supported PCB dimensions, thickness, and warpage tolerance.

- Some models are limited to small or standard boards; others support large-format PCBs used in automotive or LED applications.

- Conveyor width adjustability and board clamping options are also important for stable placement.

Application Scenarios and Recommended Machine Types

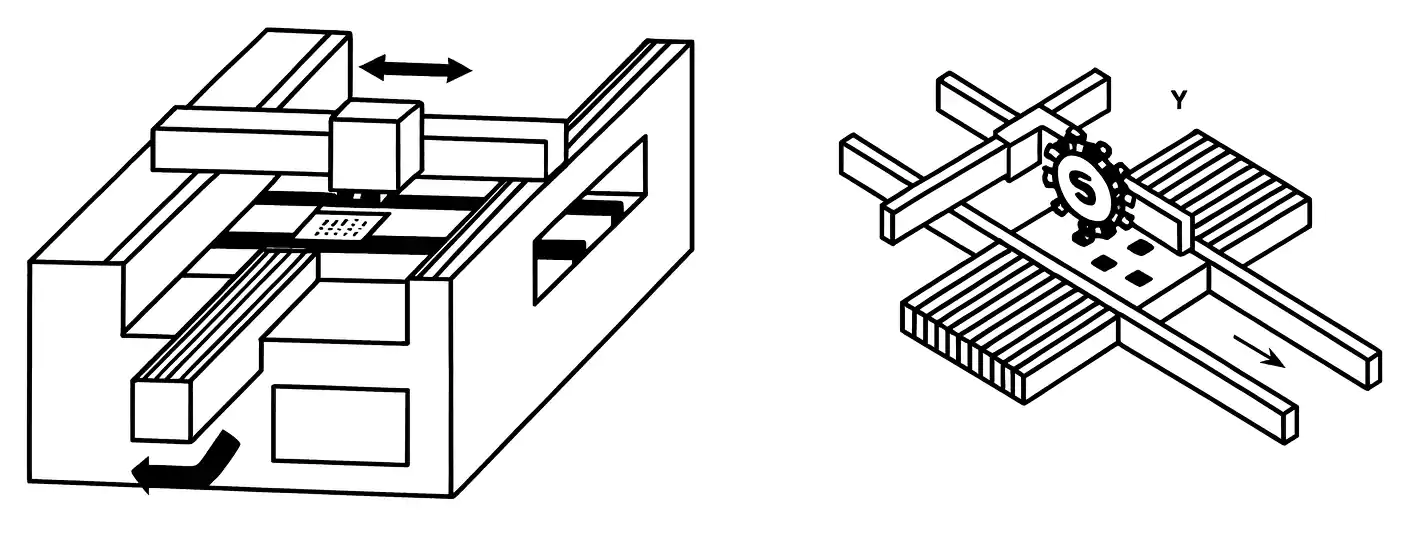

| Scenario | Recommended Machine Type | Key Considerations |

|---|---|---|

| Prototyping & Education | Manual / Semi-Automatic | Low cost, easy to use, ideal for low-volume and training |

| Small to Medium Batch Production | Semi-Automatic / Modular | Flexible setup, supports frequent changeovers |

| Mass Production | High-Speed / Inline (Flow Type) | Maximum throughput, suited for large-scale production |

| High-Mix, Complex Assemblies | Multi-Function / Modular | Supports odd-shaped components, adaptable to product mix |

Industry Trends

The SMT pick-and-place machines market continues to evolve as electronics manufacturing becomes faster, smarter, and more diversified. Several key trends are shaping the next generation of placement technology:

Miniaturization and Precision Requirements

The growing use of ultra-small components such as 0201 and 01005 packages demands higher placement accuracy, advanced vision alignment, and better motion control systems.

Smart Manufacturing and Industry 4.0 Integration

Modern SMT lines increasingly integrate intelligent software, machine learning, and real-time monitoring to improve yield, predict maintenance needs, and reduce downtime.

Hybrid and Modular Machine Designs

Manufacturers are adopting modular architectures and hybrid placement heads to combine high-speed capability with flexibility for different component sizes and shapes.

Automation and Labor Efficiency

Rising labor costs and the push for consistent quality are driving greater adoption of fully automated systems, including automatic feeders, inspection, and self-calibration features.

Sustainability and Energy Efficiency

Energy-saving drives, reduced waste, and optimized material handling are becoming standard design priorities, aligning with global sustainability goals.

Conclusion

Selecting the right SMT pick-and-place machines type is essential for efficient, high-quality PCB assembly. Manual and semi-automatic machines fit low-volume or prototype production, while fully automatic and high-speed models suit large-scale manufacturing. Modular and multi-function systems provide flexibility for complex, high-mix production lines.

As SMT technology advances, smart automation and Industry 4.0 integration will shape the next generation of pick-and-place systems. Understanding each machine type helps manufacturers align equipment capabilities with production goals—ensuring long-term efficiency and competitiveness.