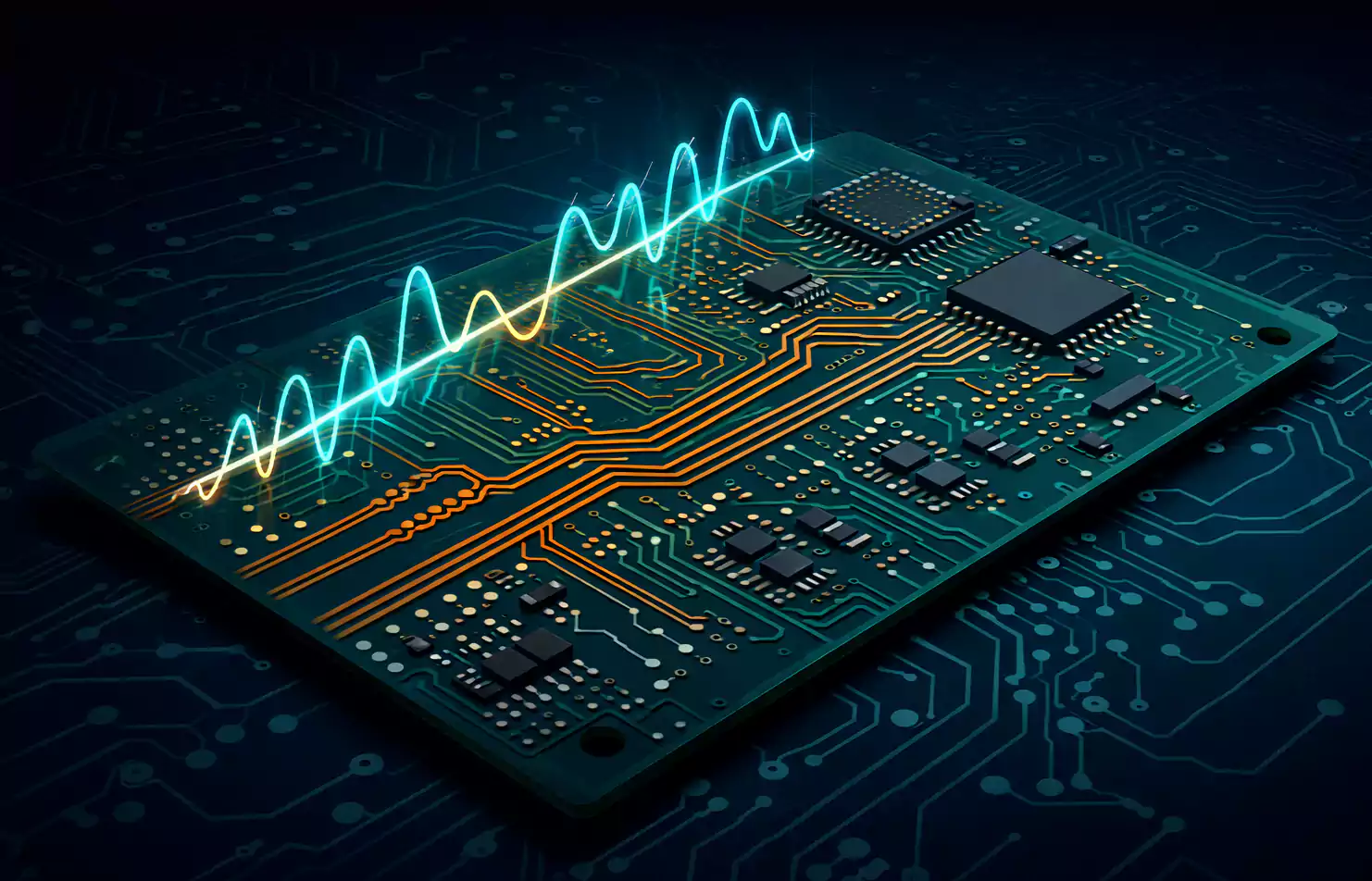

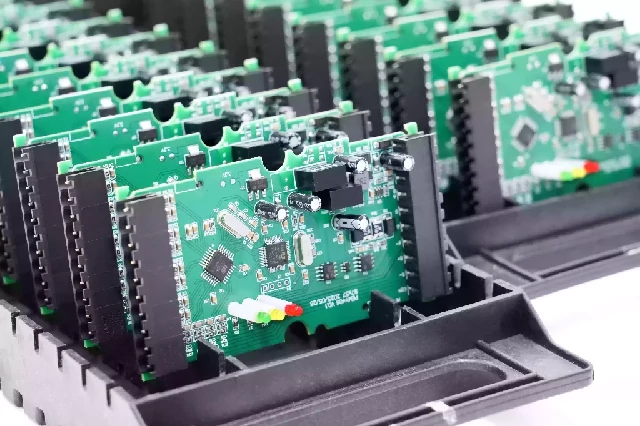

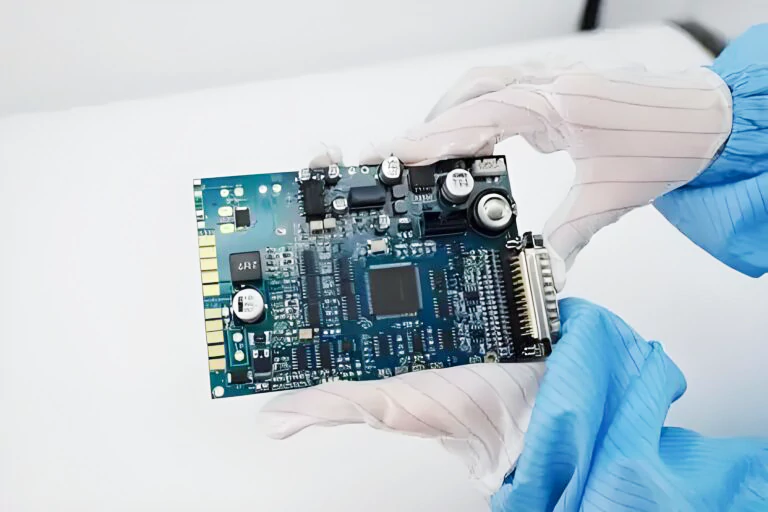

In the field of electronic manufacturing, rapid innovation and diversified product demands require highly flexible and precise production solutions. At Fast Turn PCB, we specialize in small to medium batch and multi-variety PCB and SMT assembly services, offering strong technical capabilities in high-layer count boards, HDI (High-Density Interconnect), and rigid-flex PCBs.

Whether you're testing a new prototype or launching a pilot production run, understanding the difference between small batch sampling and small batch production in SMT (Surface Mount Technology) is crucial for efficient planning and execution.

Purpose: Prototyping vs. Initial Market Launch

Small batch sampling is primarily used to verify PCB design integrity, evaluate product performance, and test production processes. At this stage, speed and flexibility are key—samples help identify design flaws, soldering issues, or layout inefficiencies before full production.

Small batch production, on the other hand, typically follows design verification. Its purpose is to meet early market demand or conduct limited market release. This phase shifts focus toward production stability, process repeatability, and consistent product quality.

Process: Agile Sampling vs. Controlled Production

Small Batch Sampling Process:

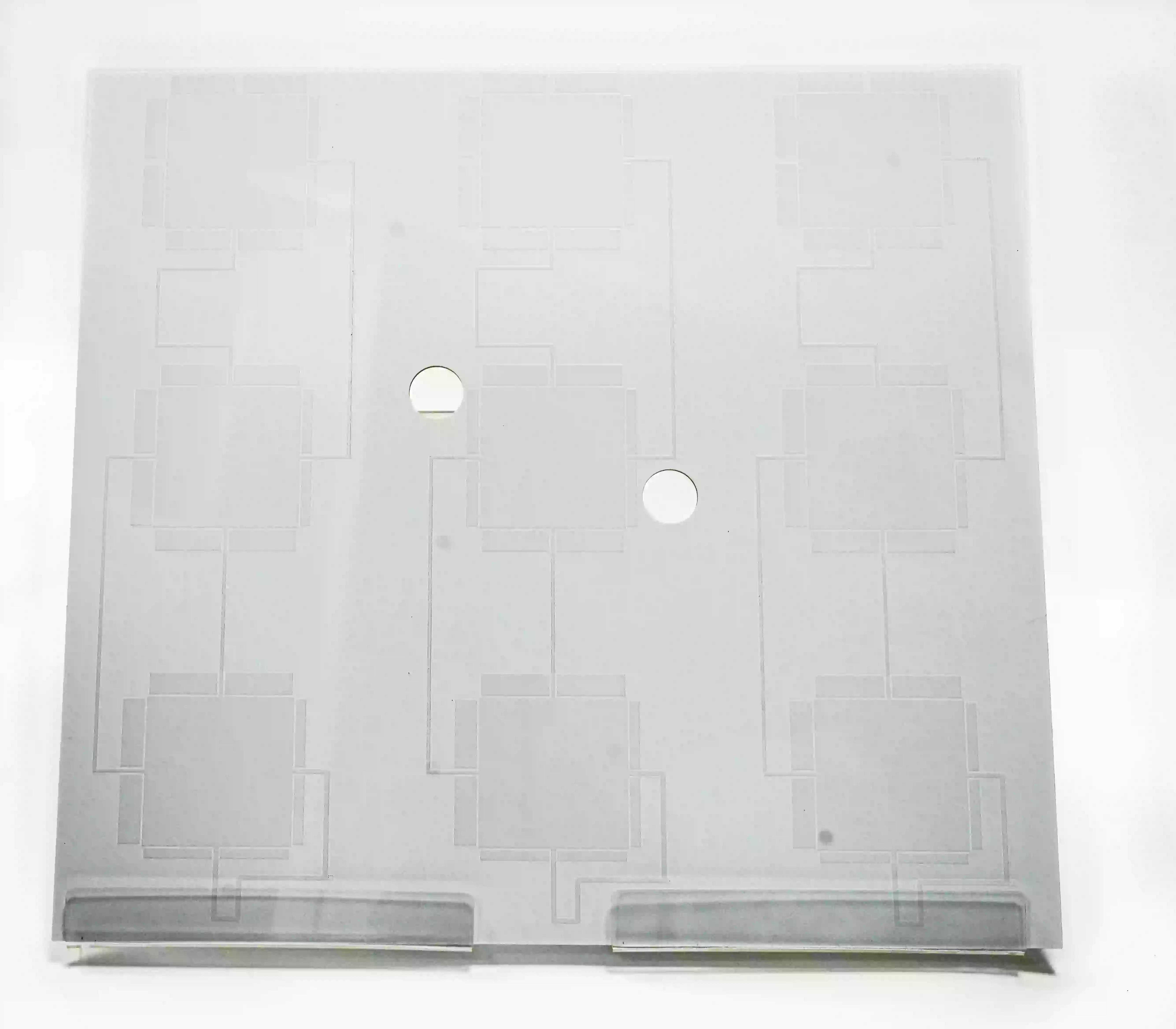

Design Confirmation: Review of PCB layout and BOM (Bill of Materials).

Material Sourcing: Fast procurement via local inventory or spot buying.

Production Prep: Quick setup of SMT lines and fixtures.

Assembly: Standard SMT process—solder paste printing, pick-and-place, reflow soldering.

Quality Testing: Comprehensive electrical and visual inspection.

Feedback Loop: Design or process changes based on test results.

Small Batch Production Process:

Pre-Production Planning: Finalized design, stable process parameters.

Optimized Procurement: Leverage bulk material sourcing to reduce costs.

Line Configuration: Setup for consistent, higher-volume output.

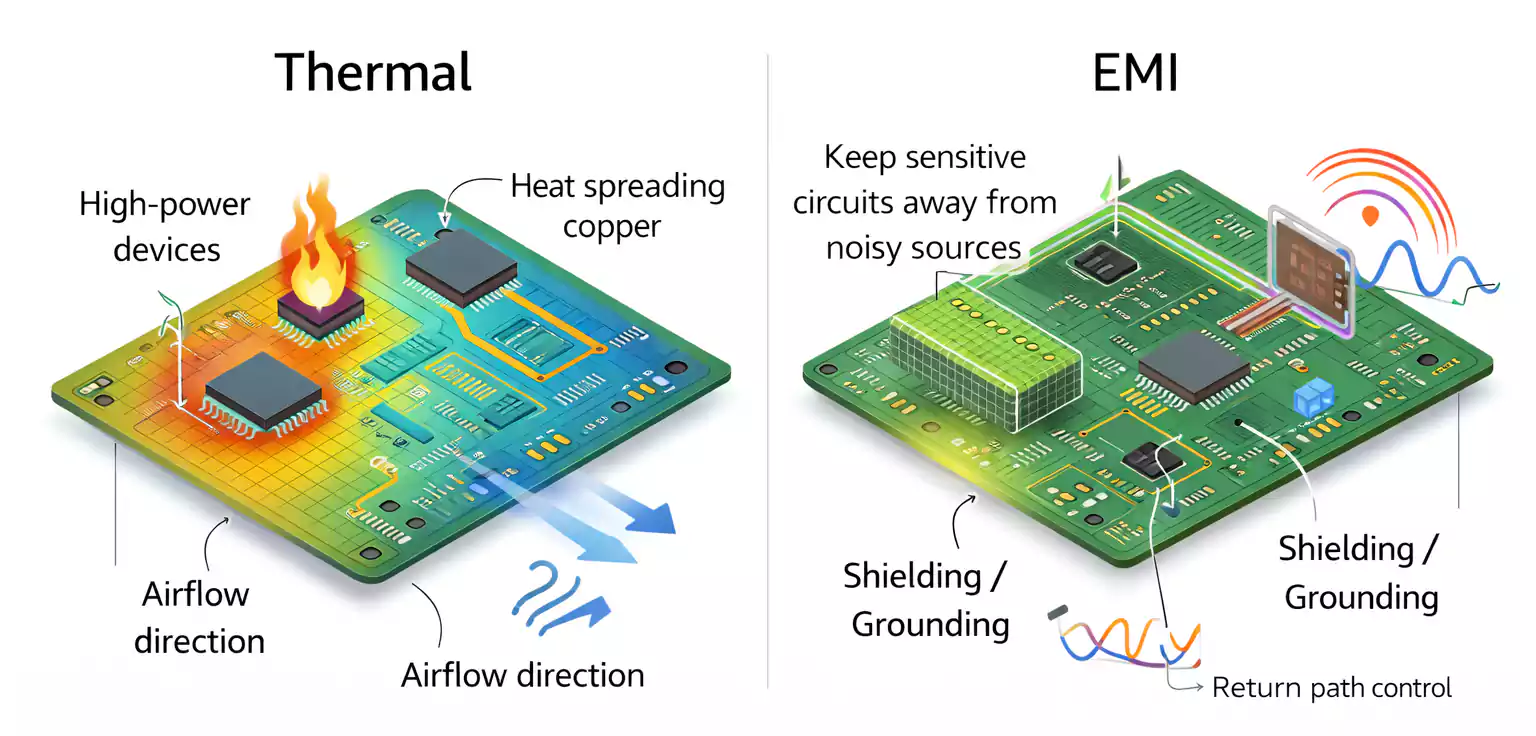

In-Line Quality Control: Automated inspection and quality assurance.

Product Testing: Full inspection or sampling based on customer requirements.

Packing & Delivery: Standard or custom packaging with on-time logistics.

Cost Control: Sampling vs. Economies of Scale

Sampling is inherently more expensive due to limited volume and one-time setup costs. Material pricing is also higher without volume discounts. However, it provides critical early feedback that helps prevent larger-scale failures.

Small batch production enables cost distribution over a larger quantity of PCBs, making it more economical per unit. Bulk purchasing, standardized workflows, and equipment amortization contribute to better cost efficiency.

Flexibility: Rapid Iteration vs. Process Stability

Sampling projects offer maximum flexibility, allowing fast iterations, layout changes, or part substitutions. This supports faster product development cycles and reduced time-to-market.

In contrast, small batch production emphasizes process consistency. While some flexibility remains, frequent changes can reduce production efficiency and impact product quality.

Fast Turn PCB: Your Trusted Partner for Complex & Custom Projects

At Fast Turn PCB, we support advanced SMT and PCB manufacturing needs including:

High-layer count PCBs (up to 40 layers)

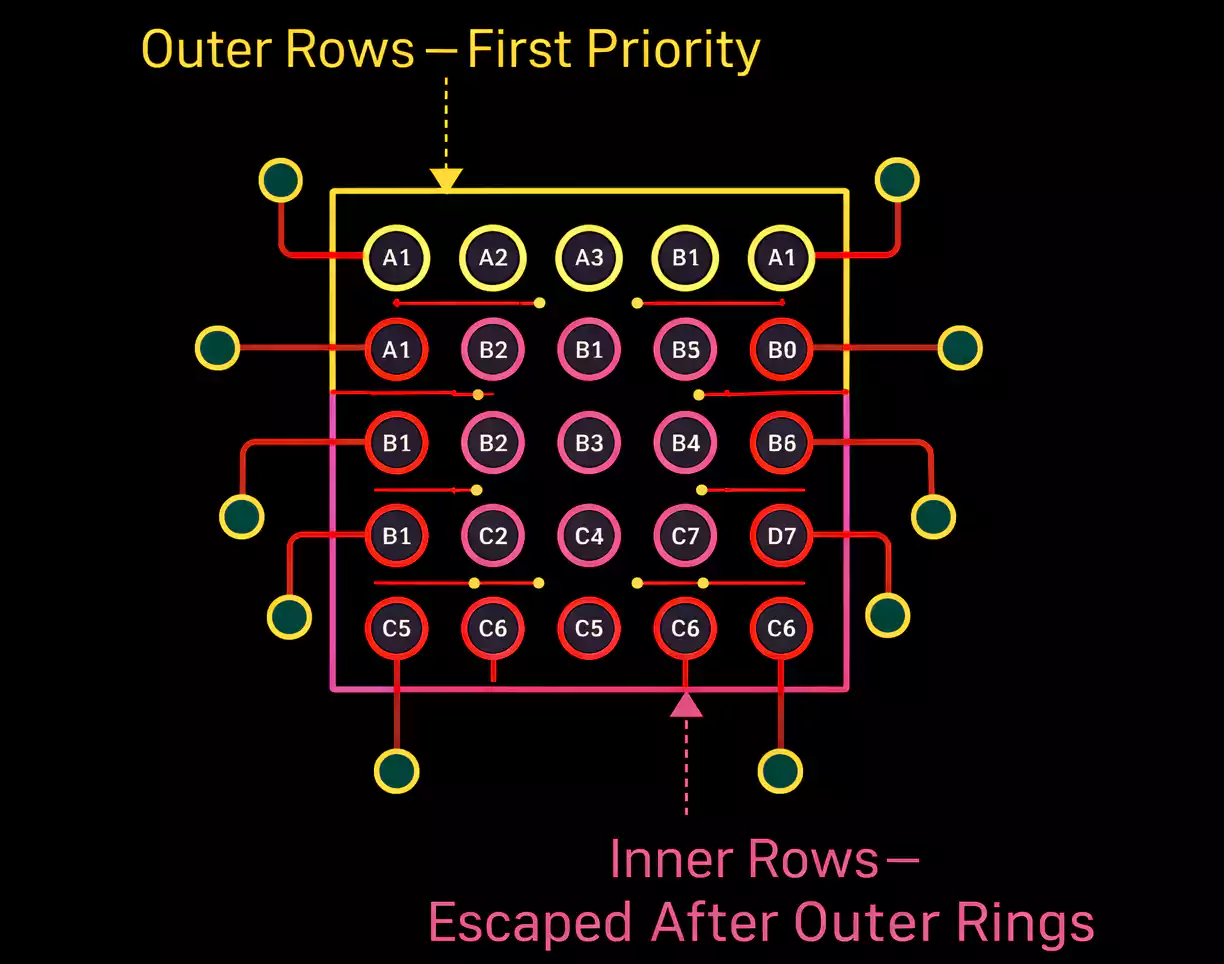

HDI boards for high-density component placement

Rigid-flex PCBs for compact, flexible applications

Mixed-technology assembly (BGA, QFN, CSP, etc.)

Quick-turn prototyping and pilot production

Our engineering team ensures design-for-manufacturing (DFM) validation, efficient sourcing, and fast turnaround times—without compromising on quality or compliance.

Partner with Fast Turn PCB for your next PCB or SMT project. Whether you're testing a prototype or scaling up to production, we deliver precision, speed, and flexibility—tailored to your exact specifications.

📩 Get a quote today or contact our team for technical consultation.