Speed is everything when developing new hardware. Quick turn PCB prototyping, offering rapid, reliable, and flexible solutions, is essential to meeting launch deadlines and driving electronics innovation across all company sizes.

But what is quick turn PCB? How fast is it? What should you look for to avoid delays? In this guide, we’ll cover what you need to know about fast turn PCB boards, how the process works, and what makes FastTurn PCBs a trusted partner for 24–72 hour prototypes and turnkey small-batch manufacturing.

What is Quick Turn PCB? Why It Matters

A quick turn PCB is a printed circuit board that is fabricated—and, if needed, assembled—on an accelerated timeline, usually within 24 to 72 hours for simple designs. Quick turn service is most valuable in the prototyping stage, where fast iterations can help engineers spot issues and move quickly toward mass production.

Typical applications for quick turn PCBs include:

- Product prototyping (EVT, DVT phases)

- Customer demos and investor pitches

- Engineering validation and bug fixing

- Design sprints and hackathons

- Emergency replacements for critical systems

Keywords like fast turn PCB, quick turn PCB assembly, and PCB prototype board all point to one thing: Speed, reliability, and flexibility—without sacrificing quality.

What Types of Quick Turn PCBs Can You Get?

Not all PCB types are suited for quick turn, but today’s top manufacturers—including FastTurn PCBs—can offer:

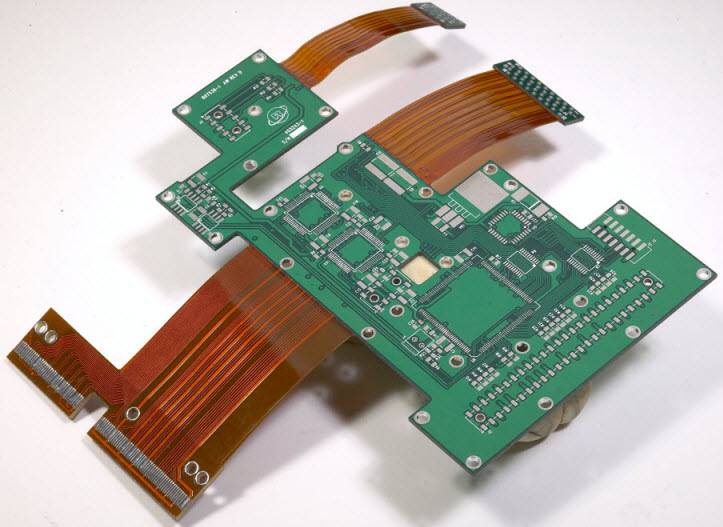

- Rigid PCBs: The most common for prototypes and final products.

- Flexible (Flex) PCBs: Ideal for wearables and compact designs.

- Rigid-Flex PCBs: For high-density, bendable electronics.

- Aluminum/Metal Core PCBs: For lighting, automotive, and power electronics.

The fastest turnaround is typically for 2- to 6-layer rigid boards, standard materials (like FR-4), and straightforward layouts. Complex features like thick copper, HDI, or specialty materials may add to lead time—but with proper communication, even these can be handled efficiently.

How Fast Is "Quick Turn"? Typical Lead Times

In the U.S. market, “quick turn” generally means:

- Bare board only:

- 2–4 layers: 24–48 hours

- 6–8 layers: 2–4 days

- 10+ layers or complex designs: 3–7 days

- PCB assembly (PCBA):

- With in-stock parts & complete files: 24–72 hours for prototypes

- With component sourcing: add 1–3 days depending on BOM and supply chain

FastTurn PCBs and other leading quick turn providers offer:

- 24-hour fabrication for simple boards

- Same-day or next-day assembly for small quantities

- Full turnkey solutions—manufacture + assembly + testing—in one streamlined process

The Quick Turn PCB Process: Step by Step

Here’s how a typical quick-turn project moves from concept to finished board:

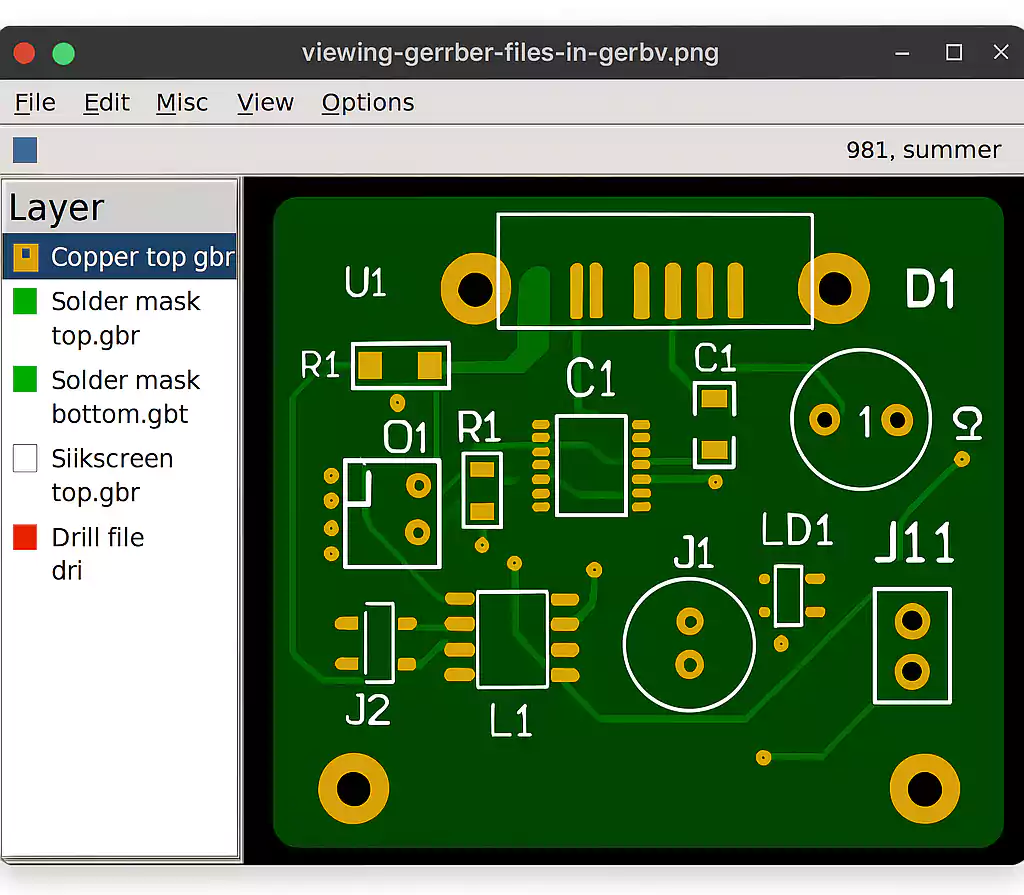

- Design and File Preparation

- Complete Gerber/ODB++ files

- Bill of Materials (BOM) with MPNs, substitute parts, and DNI (Do Not Install) marked.

- Assembly drawings and pick-and-place (PnP) files with reference coordinates and polarity.

- Engineering Review & DFM Check

- The manufacturer’s engineering team checks for errors or manufacturing obstacles.

- Clear communication here prevents delays down the line.

- Fabrication (PCB Production)

- High-speed “fast line” production for quick turn jobs

- Steel stencil prepared in parallel for assembly.

- Parts Management

- Turnkey: The factory sources all parts per BOM

- Consigned/Kitted: You supply some or all components.

- Hybrid options are possible for urgent or hard-to-find parts.

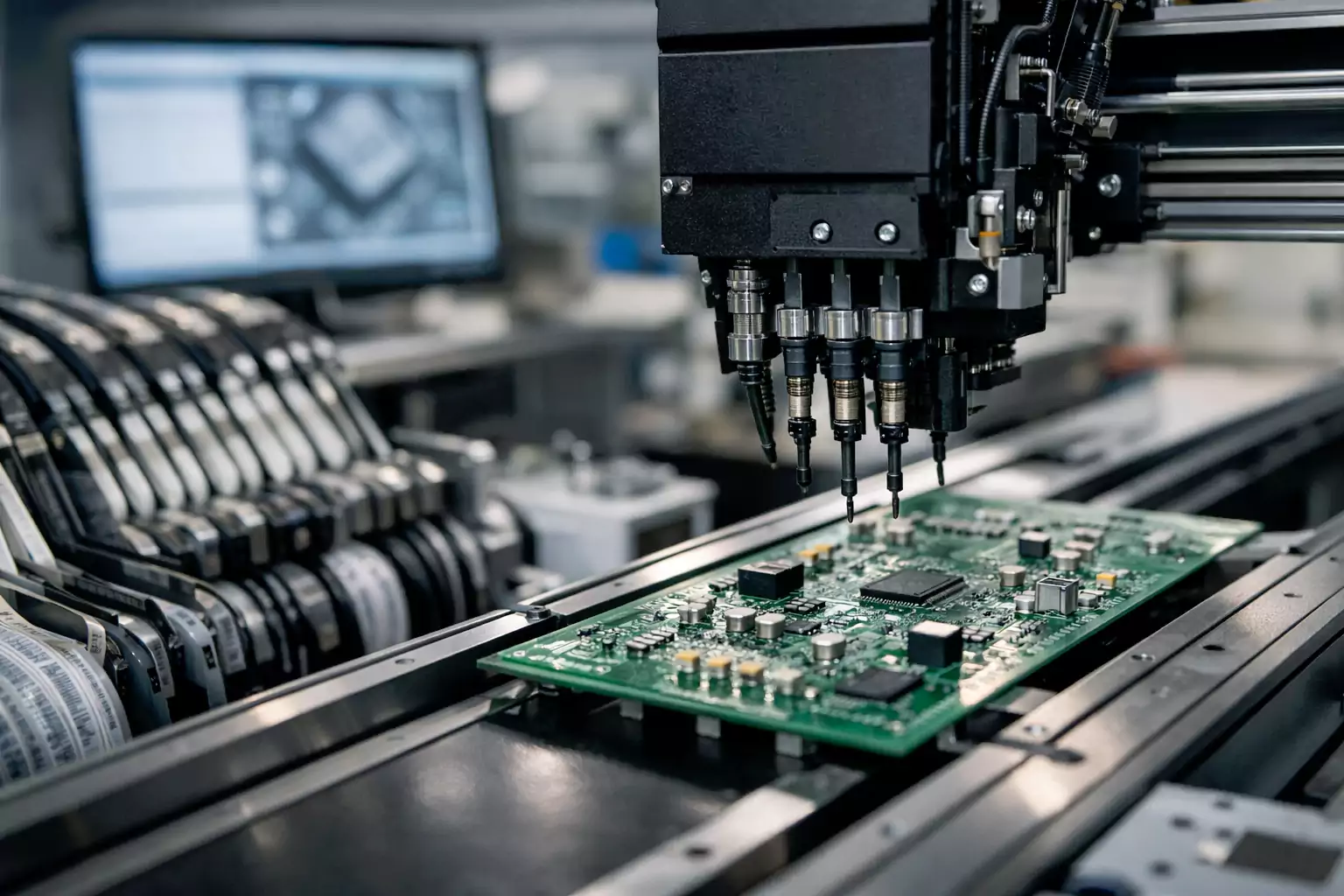

- Assembly

- SMT, through-hole, BGA, and micro components as required

- AOI (Automated Optical Inspection), X-ray, and functional tests as needed

- Quality Control & Shipping

- Every board is inspected before shipping.

- Courier pick-up scheduled for the earliest possible delivery

7 Factors That Determine Your Quick Turn Lead Time

- File Completeness

- Missing Gerbers, unclear BOM, or incomplete PnP data is the #1 cause of delays

- Board Complexity

- Higher layer counts, HDI, controlled impedance, and thick copper require more process steps.

- Material and Part Availability

- Common materials and parts are usually stocked for quick turns; rare items may slow things down.

- One-Stop vs Split Process

- A single supplier (like FastTurn) offers faster results than separate board/assembly vendors.

- Testing Requirements

- X-ray, AOI, or ICT testing adds time but improves reliability—choose wisely for your needs.

- Order Cut-Off and Confirmation

- Orders received before daily cut-off times are prioritized for next-day output.

- Communication Speed

- Fast response to engineering questions = faster boards in your hands

How to Pass DFM and DFT Checks (and Save Time)

Quick turn works best when your design is production-ready. Here’s how to keep your project on track:

- Clear Layer Stack and Soldermask: Ensure all layers and soldermask openings are properly defined

- Polarity & Silkscreen: Mark all diodes, electrolytics, and IC Pin 1; avoid overlapping silkscreen with pads

- BOM Best Practices: Include Manufacturer Part Numbers (MPN), preferred substitutes, and clear DNI markings

- Pick-and-Place File Accuracy: Use a consistent origin and rotation convention; double-check for BGA and small components

- Show Stopper Prevention: Triple-check for missing BOM lines, undefined substitute parts, or coordinate errors.

Quick Turn PCB Assembly: Materials, Turnkey, and Split-Kitting

PCB assembly (PCBA) is where delays often happen—especially when parts are hard to source. Top quick turn providers like FastTurn offer flexible solutions:

- Turnkey Assembly: FastTurn sources everything. Easiest for you and fastest overall, but may need flexibility on substitute brands for speed.

- Consigned (Kitted) Assembly: You send the components. Great for custom or rare parts, but shipping and check-in may slow things down.

- Hybrid Approaches: For mission-critical or last-minute projects, partial consignment plus factory-sourced parts is possible.

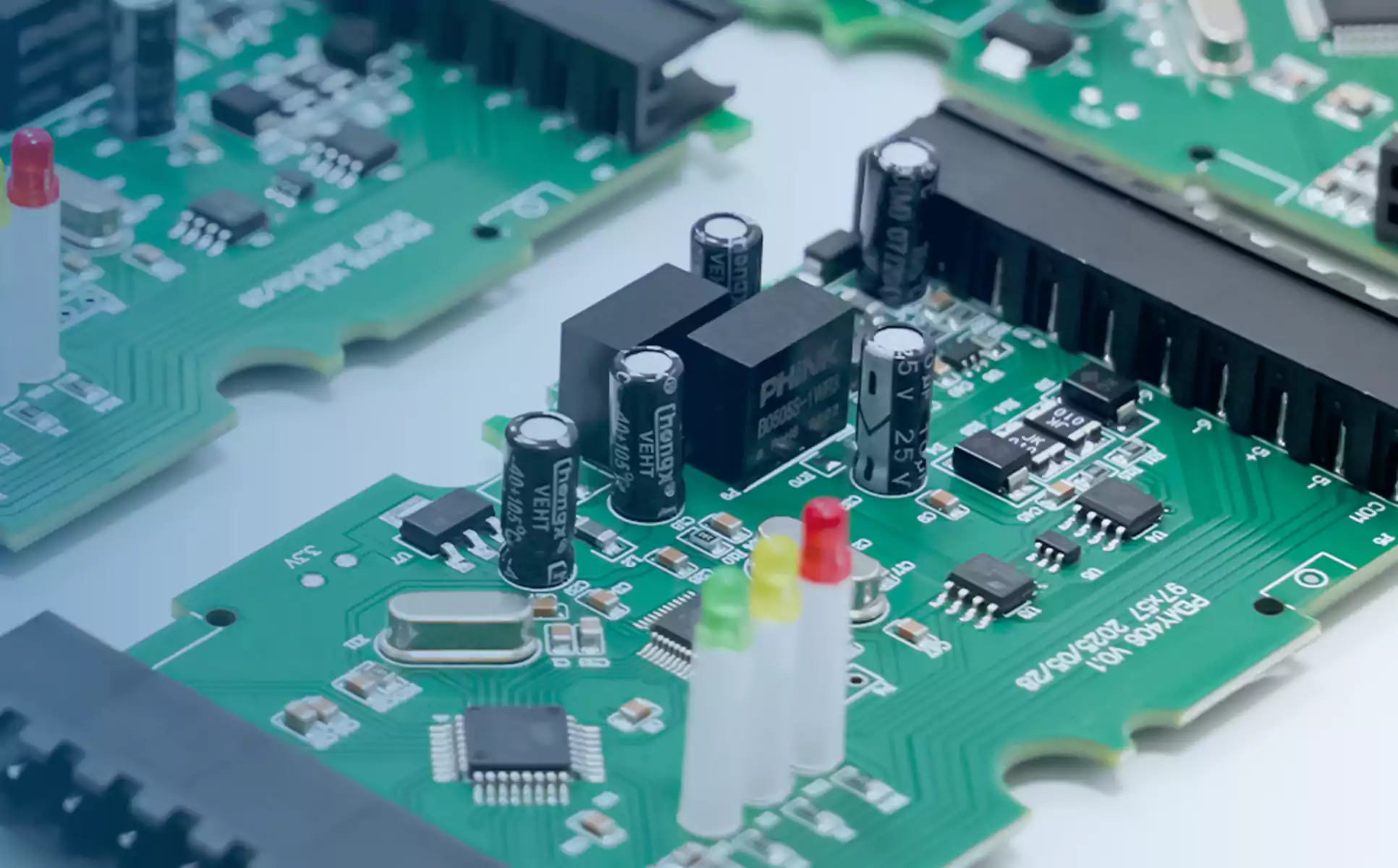

Quality and Trust: Fast Does Not Mean Risky

With FastTurn PCBs and similar leading providers, speed never comes at the cost of quality. Key practices include:

- Dedicated fast-turn production lines—not squeezed in with standard orders.

- Engineering review and DFM upfront

- In-house assembly and inspection: AOI, X-ray, functional testing available as needed

- Certifications: ISO9001, UL, IPC Class 2/3, ITAR (as required)

This level of control lets you trust your prototypes—even when they ship out just 24 hours after you order.

Choosing the Right Quick Turn PCB Fabrication Partner in the USA

When selecting a quick-turn PCB partner, prioritize quality and turnaround time. Partnering with a certified CM offering turnkey PCBs ensures reduced lead times (TAT) and consistent quality.

Key Considerations:

- Location: While not based in the USA, we work closely with trusted manufacturers to ensure fast delivery and seamless supply chain management, reducing turnaround time.

- Product Lead Time: A faster prototype production leads to quicker design finalization. We ensure rapid prototyping to meet your deadlines.

- Certifications: Our operations comply with global standards, including IPC, ISO, UL, and RoHS, ensuring high-quality, certified products.

- Consistency: We deliver consistent quality, from small-scale prototypes to large production runs.

- Communication & Support: Clear communication is vital. We maintain constant collaboration with clients, ensuring all concerns are addressed promptly.

By choosing a reliable partner with these factors in mind, you ensure a smooth and efficient production process.

Frequently Asked Questions (FAQ)

How fast is a quick turn PCB order?

For simple designs, bare boards can be ready in 24–48 hours and assembled prototypes in 24–72 hours, depending on file and part readiness.

Can you do a quick turn with just PCB files?

For bare boards—yes. For PCBA (assembly), you must provide a full BOM, pick-and-place data, and preferably use available parts.

Which board types are supported for quick turn?

Standard rigid, flex, rigid-flex, and some metal-core PCBs can all be quick-turn, especially at lower layer counts and with standard materials.

How is quality ensured with quick turn?

Dedicated fast lines, thorough DFM reviews, and automated inspection (AOI/X-ray) ensure fast boards don’t mean risky boards.

Why Choose FastTurn PCBs for Your Next Quick Turn Project?

FastTurn PCBs specializes in quick turn PCB fabrication and assembly, serving engineers and product teams across the USA. Here’s what sets us apart:

- Full turnkey and assembly under one roof

- 24-hour prototype options for many board types

- Friendly, responsive engineering support

- Transparent pricing and fast online quotes

- Industry certifications and proven track record

Whether you need a single prototype or a hundred small-batch assemblies, FastTurn helps you move fast, build smart, and launch with confidence.

Ready to get started? Contact FastTurn PCBs for a fast quote or engineering review today!