Introduction

In today’s fast-paced electronics industry, speed is everything. Whether you're a hardware startup racing to prototype, an engineer iterating a new design, or a manufacturer trying to meet tight deadlines, quick turn PCB and assembly services can make all the difference. These services are designed to deliver printed circuit boards (PCBs)—either bare boards or fully assembled units—in as little as 24 to 72 hours.

But not all quick turn services are created equal. The success of a rapid PCB project depends on much more than just speed. Factors such as design readiness, supplier reliability, and component availability play a crucial role in ensuring on-time delivery and quality assurance.

In this article, we’ll explain what quick turn PCB and PCB assembly services are, what impacts turnaround times, how to prepare your files for a smooth process, and why choosing the right manufacturing partner—like Fast Turn PCBs—can help you meet your development goals faster and more reliably.

What Is Quick Turn PCB vs Assembly?

A quick turn PCB refers to a printed circuit board that is manufactured and delivered on an expedited timeline—typically within 24 to 72 hours. This is ideal for engineers and product teams who need to rapidly validate a design, troubleshoot issues, or meet urgent deadlines. Quick turn PCB services focus specifically on bare board fabrication, including drilling, etching, plating, and solder masking.

On the other hand, quick turn PCB assembly (also called quick turn PCBA) takes things one step further. It not only includes the production of the PCB but also component sourcing, SMT (surface-mount technology) or through-hole assembly, and functional testing. Essentially, it provides a fully assembled and ready-to-test board, delivered in days instead of weeks.

Here’s a quick comparison to clarify the differences

| Aspect | Quick Turn PCB | Quick Turn PCB Assembly |

|---|---|---|

| Includes | Bare board fabrication only | Fabrication + Component Assembly |

| Turnaround | 24–72 hours (typical) | 2–5 days (depending on BOM) |

| Complexity | Lower | Higher (depends on part count & sourcing) |

| Best for | Design validation, bare board testing | Functional prototyping, pilot runs |

While both services accelerate time-to-market, quick turn PCB assembly delivers a complete solution for teams requiring fully functional prototypes or low-volume production.

Top 5 Factors That Impact Turnaround Time

When it comes to quick turn PCB fabrication and assembly, speed isn’t just about how fast a factory can run machines—it depends on a range of technical and logistical factors.

1. PCB Layer Count and Design Complexity

The more layers your PCB has, the longer it takes to manufacture. A simple 2-layer board can often be fabricated within 24 hours, while 8-layer or HDI (High-Density Interconnect) designs may require special processing that adds days to the schedule. Complex via structures, such as blind, buried, or via-in-pad configurations, can also increase turnaround time.

2. Material Selection

Using standard materials like FR-4 speeds up the process because they're readily available and don’t require special handling. In contrast, high-frequency laminates, high-Tg, or halogen-free materials may require additional lead time for sourcing or processing.

3. Component Availability

For quick turn PCB assembly, component sourcing is often the biggest bottleneck. If your BOM (Bill of Materials) includes hard-to-find or long lead time components, your entire project can be delayed. To avoid this, choose readily available parts or provide approved substitutes to your assembler.

4. Data File Readiness

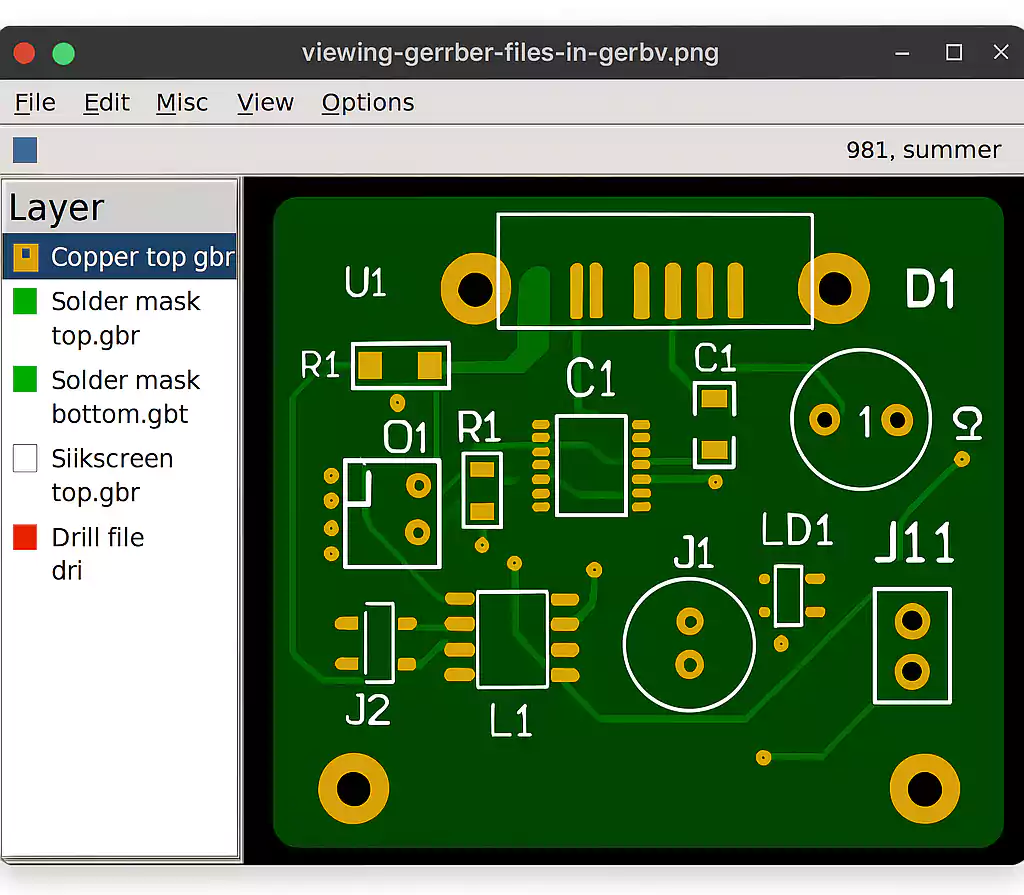

Incomplete or improperly formatted files are a common cause of delays. Make sure to submit accurate Gerber files, drill files, pick-and-place data, and a clear BOM. Any missing or inconsistent data can trigger back-and-forth communication, which in turn can push back the production schedule.

5. Special Requirements and Testing

Advanced testing (like X-ray inspection, functional testing, or flying probe) adds time but is often necessary for quality assurance. Similarly, requests such as conformal coating, selective soldering, or custom packaging may require extra processing steps.

How to Prepare for Fast Delivery

Achieving true quick turn PCB or assembly delivery—whether in 24, 48, or 72 hours—starts well before production begins. The most significant delays often stem from incomplete files, unclear requirements, or components that are difficult to source. Here’s how to avoid those setbacks and keep your project on track.

1. Simplify Your PCB Design

The more complex your board, the longer it takes to manufacture. Try to limit the layer count, avoid blind or buried vias, and adhere to standard shapes and sizes whenever possible. Simple, well-structured designs are not only faster to produce but also easier to inspect and assemble.

2. Provide Complete and Accurate Files

Make sure to include all necessary manufacturing and assembly documentation:

- Gerber files (RS-274X format recommended)

- Drill file

- Bill of Materials (BOM) with part numbers and approved alternates

- Pick-and-place file with component reference designators and orientations

- Assembly drawings and any special instructions

Double-check that all files are consistent and properly named. File issues are one of the top causes of production delays.

3. Choose Readily Available Components

For fast-turn PCB assembly, always select components that are in stock and available for immediate purchase. If any part has a long lead time or low availability, it can halt your entire schedule. We recommend working with your supplier to identify drop-in replacements or approved alternates in advance.

4. Communicate Special Requirements Early

If your board needs specific tests (such as AOI, X-ray, or functional testing), coating, or unique packaging, let your provider know up front. Last-minute additions to the process can slow things down and increase costs.

Why Choose Fast Turn PCBs for Quick Turn Service?

Fast Turn PCBs is your trusted partner for quick turn PCB prototyping and assembly. Whether you’re in consumer electronics, medical devices, automotive, or aerospace, our team helps you build and deliver boards faster—without compromising on quality or service.

Our advantages include:

- State-of-the-art production lines equipped with automated SMT machines, AOI inspection, X-ray testing, and precision soldering systems

- Over a decade of expertise in PCB manufacturing, assembly, and rapid prototyping

- Real-time engineering support for file review, DFM checks, and urgent design updates

- Certified to IPC and ISO standards, ensuring reliability and compliance with industry benchmarks

- Fast, flexible services including bare board fabrication, full turnkey assembly, and ultra-low MOQs—ideal for prototypes and low-volume runs

- Same-day production starts available for standard 2–4 layer boards with fast-track delivery in 24–72 hours

We don’t just deliver boards—we help you accelerate development cycles, reduce time-to-market, and gain a competitive edge. With Fast Turn PCBs, you get a seamless, end-to-end service built for speed, accuracy, and scalability.

Conclusion

In today’s fast-moving electronics industry, every hour counts. Whether you’re building a prototype, testing a new design, or launching a product, quick turn PCB fabrication and assembly services can significantly reduce your development cycle and time to market.

By understanding the difference between fabrication and assembly, optimizing your design files, and working with a trusted partner like Fast Turn PCBs, you can eliminate delays, improve product quality, and keep your projects on schedule.

At Fast Turn PCBs, we combine speed, precision, and expert support to deliver high-quality boards in as little as 24–72 hours. From one-off prototypes to low-volume turnkey builds, we’re here to help you build faster—with confidence.

Ready to get started? Upload your Gerber files and BOM today for a fast, no-obligation quote—and see how Fast Turn PCBs can accelerate your next project.