In electronics manufacturing, PCBA programming (commonly known as burning or downloading) refers to the process of writing pre-compiled code into the memory of a PCBA board. A reliable and precise programming process ensures the product operates as designed and delivers stable performance. This guide provides a comprehensive overview of the PCBA programming workflow, common methods, verification, testing, error handling, and the value-added services we offer to support high-quality production.

What Is PCBA Programming (Burning)?

PCBA programming means writing binary program files (such as .hex or .bin) into the memory or microcontroller on a PCBA board. This step is critical to enable the device to perform its intended functions according to software design.

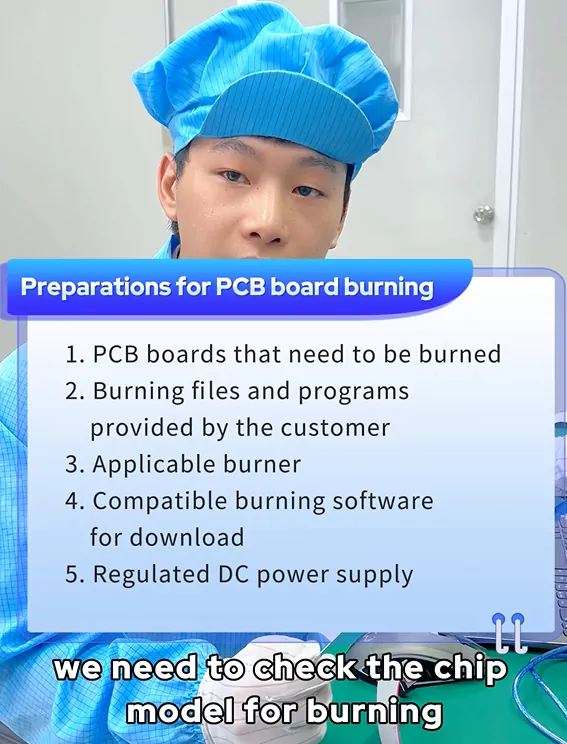

Preparation Before Programming

Before starting the programming process, several key preparations are necessary:

Program File Preparation: The development team writes and compiles the software according to product requirements, generating binary files for programming.

Select Programming Method: The choice of programming method depends on production needs:

Offline programming: Suitable for mass production or pre-programming chips before assembly.

Online programming: Ideal for on-board programming during assembly, debugging, or field updates.

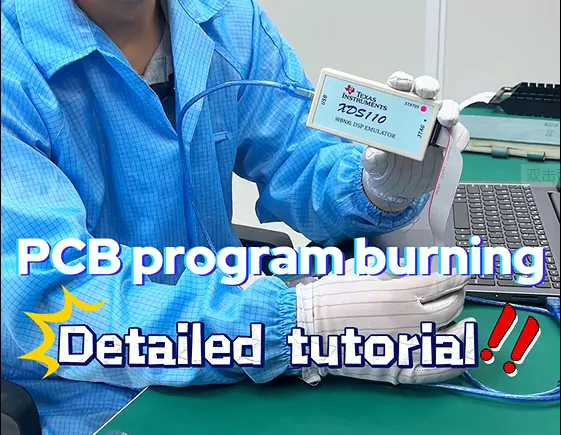

Prepare Programming Tools and Fixtures: Ensure that the programmer, adapters, cables, power supply, and fixtures are ready and reliable.

Detailed PCBA Programming Process

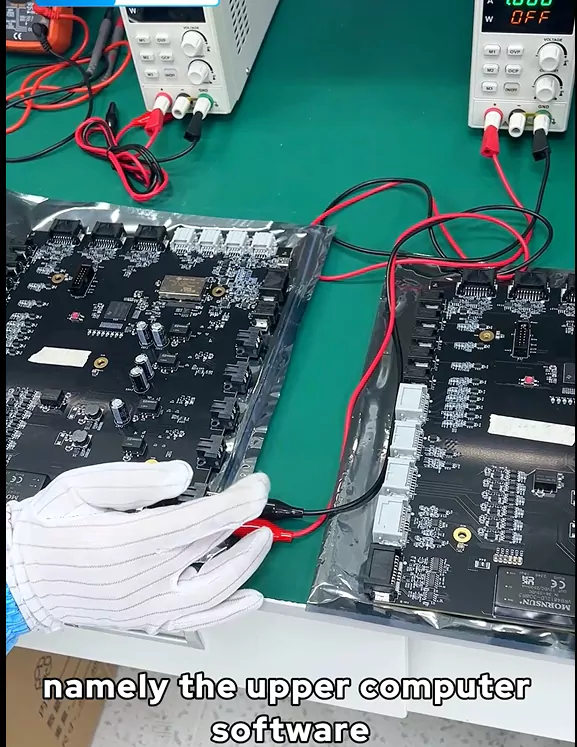

Connect the Programming Tool

Securely connect the PCBA board to the programming tool, including power supply and data cables. A stable connection prevents interruptions and errors during programming.

Set Programming Parameters

Configure settings such as chip model, memory type, and programming speed according to the specifications of the target program. Accurate settings are essential for success.

Start Programming

Begin the programming process. The tool writes the program into memory while displaying progress and status, allowing operators to monitor in real-time.

Verification and Functional Testing

After programming, rigorous verification and testing are crucial:

Data Verification: Read back data from the memory and compare it with the original program to confirm integrity and correctness.

Functional Testing: Run specific test programs to ensure the PCBA performs as expected.

Value-Added Services: We offer custom test fixtures and automated test solutions to help clients improve efficiency and product consistency.

Error Handling and Record Keeping

Programming errors can occur due to various reasons, such as connection issues, chip faults, or power instability. Our approach includes:

Re-programming or replacing faulty components;

Analyzing root causes (e.g., hardware wear, interference);

Recording error data for traceability and process improvement.

We provide detailed reports and traceable data to help customers optimize their manufacturing processes and avoid repeated issues.

Why Choose Our PCBA Programming Service?

One-stop offline and online programming solutions

Custom programming + functional test fixture design

Professional FAE support for tailored programming solutions

Full traceability and error analysis reporting

If you are looking for expert advice or customized PCBA programming solutions, contact us — we’re here to help you achieve reliable, high-quality manufacturing.