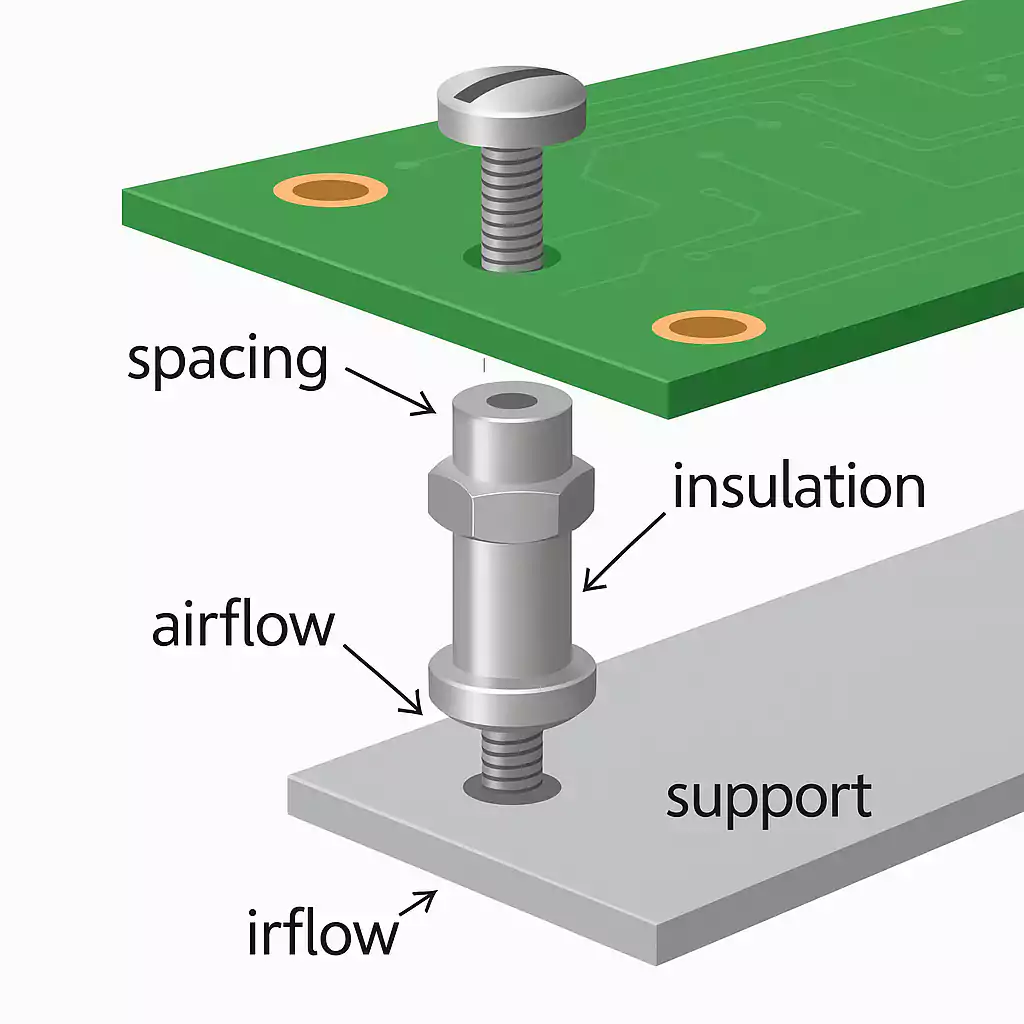

When you look inside a computer, router, or control box, you’ll find small metal or plastic posts holding the circuit board in place. Those posts are called PCB standoffs — simple yet critical components that provide your board with the right spacing, insulation, and support.

This guide explains what PCB standoffs are, why they matter, the main types and materials, how to choose the right size, and how to install them correctly.

PCB Standoffs and Common Accessories

A PCB standoff (sometimes called a spacer or pillar) is a small post used to hold a printed circuit board (PCB) at a fixed distance from another surface — such as a chassis, another board, or a panel.

Standoffs prevent the board from touching other components, reducing the risk of short circuits and mechanical stress. They also create space for airflow and wiring under the board.

Typical accessories used with standoffs include screws, nuts, washers, and grounding pads. Many manufacturers sell full PCB standoff kits that include a mix of sizes (M2–M3, #4–40, etc.) and materials.

Spacer vs. standoff:

- A spacer is usually a smooth tube with no threads, used with bolts on both sides.

- A standoff has internal or external threads so you can screw it directly into the board or case.

Why PCB Standoffs Matter

Using standoffs offers both electrical and mechanical benefits:

- Electrical insulation: Prevents the bottom of the PCB from shorting to a metal surface.

- Mechanical strength: Holds the board firmly, even in high-vibration environments.

- Heat management: Creates space for airflow and cooling below the board.

- Easy maintenance: Allows quick removal and reassembly during repair or testing.

Without proper spacing, a PCB can warp, overheat, or fail due to poor grounding or vibration.

How to Choose the Right PCB Standoff

Choosing the right standoff is simple if you follow three basic steps.

1. Define the height or spacing

Measure the tallest component on your PCB and add some clearance. Typical standoff lengths range from 3 mm to 25 mm (1/8 in to 1 in). Shorter lengths are common in compact electronics; longer ones are used for stacked boards or tall heat sinks.

2. Match the installation surface

- Metal chassis or thin panels: Use PEM self-clinching standoffs for a permanent, flush-mount fit.

- Plastic or FR-4 boards: Use threaded standoffs with screws or snap-in plastic supports.

- Temporary prototypes: Use adhesive or press-fit standoffs for quick assembly.

3. Choose the thread and hole size

Most common thread types: M2, M2.5, M3 (metric) or #4-40, #6-32, #8-32 (inch).

Drill holes that match the screw size, but leave slight clearance so the screw passes through easily.

| M2 | 2.2 mm | 1.0–1.6 mm | 3–10 mm |

| M2.5 | 2.7 mm | 1.2–2.0 mm | 4–15 mm |

| M3 / #4-40 | 3.2 mm | 1.6–2.4 mm | 6–20 mm |

| #6-32 | 3.7 mm | 1.6–3.2 mm | 8–25 mm |

3.1 Common Standoff Materials

Different materials serve different purposes:

- Nylon / Plastic: Light, non-conductive, low cost. Ideal for insulation or low-load areas. Rated UL 94 V-2 or better.

- Brass: Strong, corrosion-resistant, and easy to machine. Often nickel-plated for appearance.

- Aluminum: Lightweight and good for thermal management.

- Stainless steel: Maximum strength and corrosion resistance, ideal for outdoor or vibration environments.

3.2 Thread & Gender Types

Standoffs come in several shapes and connection types:

- Female–female (internal–internal): Both ends have threaded holes.

- Male–female: One side has a screw, the other a threaded hole.

- Male–male: Screws on both ends for through-mount stacking.

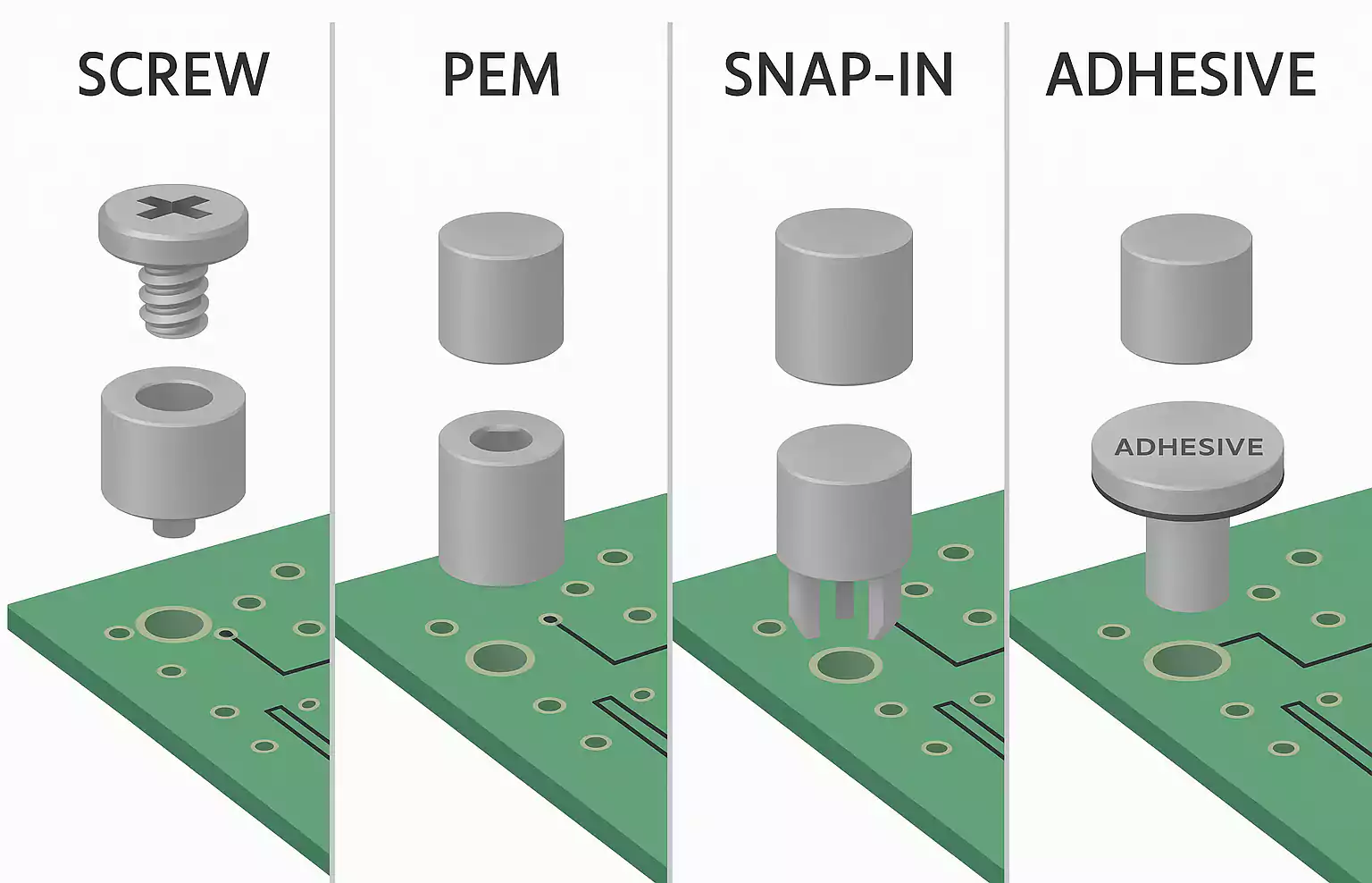

- Snap-in or push-fit: Plastic clips that snap into board holes, no tools needed.

- Adhesive base: Stick directly onto a surface, used for lightweight boards.

Each type fits a different assembly style. For example, male–female brass standoffs are popular for connecting a PCB to a metal case, while snap-ins are suited to quick assembly in consumer products.

3.3 Installation Methods – How to Use PCB Standoffs

Installing a standoff is easy, but following the correct steps prevents cracks or misalignment.

A. Screw-mounted type

- Drill or use pre-plated holes in the PCB.

- Place the standoff and insert a screw through the board.

- Tighten gently — too much torque can damage FR-4 or nylon.

Use washers or lock nuts if vibration is expected.

B. PEM self-clinching standoffs

PEM® is a well-known brand of self-clinching hardware. These standoffs are pressed into a pre-punched hole in a thin metal sheet (usually 0.8–2 mm). Under pressure, the knurled ring locks permanently into the sheet, leaving the opposite side flush.

They are ideal for metal enclosures and grounding connections.

Common series: SO, BSO, TSO, DSO, and grounding types like SOAG or SOSG.

C. Snap-in or adhesive supports

Plastic supports can clip directly into PCB holes or stick to a base using adhesive pads. They’re perfect for quick assembly or low-load applications, but not for heavy boards or high heat.

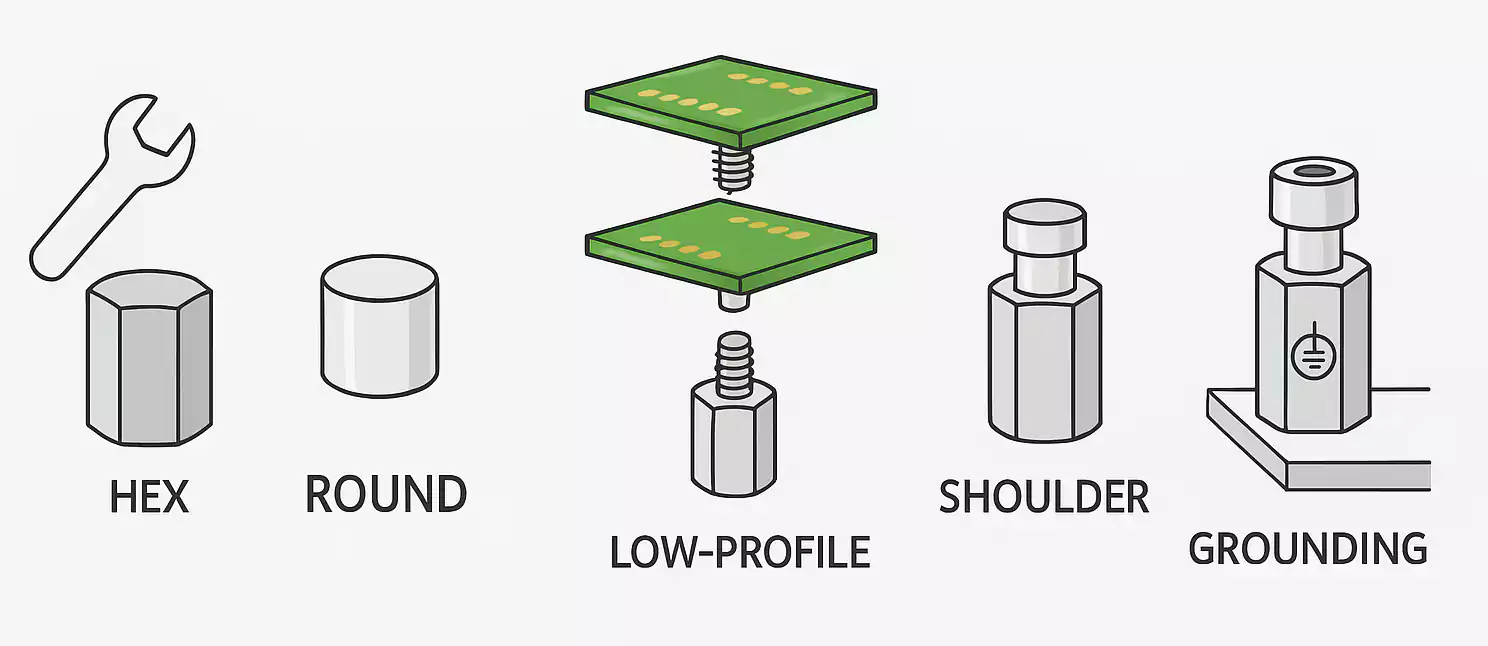

Common Design and Shape Options

PCB standoffs come in many shapes: hexagonal, round, low-profile, stackable, and shoulder types.

- Hex standoffs are easy to grip with a wrench.

- Round standoffs save space in tight layouts.

- Stackable standoffs let you mount multiple boards in layers.

- Grounding standoffs (metal) can connect the PCB to chassis ground for EMI shielding.

Choose shapes based on space, accessibility, and assembly method.

Real-World Applications

You can find standoffs in almost every electronic device:

- Networking gear: Routers, base stations, and antennas use standoffs to separate stacked RF boards.

- Industrial control systems: Metal standoffs keep PCBs rigid and stable under vibration.

- Computers and servers: Create air channels for cooling and secure heavy heat sinks.

- Automotive electronics: Use stainless or aluminum for corrosion and vibration resistance.

When using standoffs for grounding, make sure the metal surface is clean and free of paint or oxide. If the contact isn’t perfect, add a conductive washer to keep a solid electrical connection.

FAQs about PCB Standoffs

What are PCB standoffs?

They are small posts that support and separate a PCB from other parts. They prevent shorts, provide rigidity, and improve heat flow.

What is the point of standoffs?

Their purpose is to create a safe distance and stability — keeping the board secure, cool, and easy to service.

How to use PCB standoffs?

Drill the mounting holes, place the standoff, and secure it with a screw or press-fit. Choose the method (screw, PEM, or snap-in) based on your material and load.

What is a PEM standoff?

A PEM standoff is a self-clinching standoff made by PennEngineering. It presses into thin sheet metal to create a strong, permanent threaded post. Common series include SO, BSO, TSO, DSO, and grounding types SOAG/SOSG.

What sizes do PCB standoffs come in?

Typical threads are M2–M3 and #4-40–#8-32, with lengths from 3 mm up to 25 mm (1/8–1 in). Custom sizes exist for thicker boards or heavy components.

Nylon vs. metal standoffs – which is better?

Nylon is light and non-conductive, perfect for insulation and low heat. Metal standoffs (brass, aluminum, stainless) are stronger, durable, and support grounding.

Can I 3D-print standoff spacers?

Yes, for prototypes or light loads. For production, injection-molded or machined parts give tighter tolerances and better strength.

Conclusion

PCB standoffs are essential for safe, stable, and reliable board assemblies. They provide precise spacing, insulation, and support while improving airflow and durability.

Selecting the right standoff—by height, material, and mounting method—ensures mechanical strength and electrical safety. Whether nylon, metal, or PEM self-clinching, each type serves a clear purpose in modern electronic design.

A well-chosen and properly installed standoff keeps every PCB secure, aligned, and ready for long-term performance.