At Fast Turn PCB, Our equipment and rigorous testing processes ensure that every PCB meets the highest standards of quality and reliability. In this blog post, we'll explore the essential steps involved in PCB appearance and internal quality inspection, as well as the cutting-edge equipment that powers our production line, including LDI (Laser Direct Imaging), Lamination, Gold Finger (ENIG), AOI (Automated Optical Inspection) Scanners, Flying Probe Testers, and Impedance Testers.

PCB Appearance Inspection: Ensuring Quality at First Glance

Board Inspection:

Our advanced equipment helps to detect any imperfections on the surface of the PCB. We ensure that the board is flat, free from bumps, scratches, or stains, and that the solder pads and wire connections are intact. Any potential defects such as short circuits or damage to the copper traces are identified during this process.

Identification Inspection:

We use precision inspection techniques to verify that identification markings, such as the manufacturer's logo, production date, and batch number, are clear and visible. Our boards also carry necessary certification marks like UL and CE for guaranteed compliance with international standards.

Dimensional Measurement:

Using high-precision instruments like calipers and laser measurement tools, we measure the length, width, and thickness of the PCB. This ensures that all dimensions, including aperture sizes and positions, are accurate and align with the design specifications.

Welding Quality Inspection:

Our Automated Optical Inspection (AOI) systems conduct thorough visual checks of solder joints, ensuring they are smooth, full, and without defects such as cold soldering. Additionally, we use advanced X-ray and infrared detection equipment to identify any voids or internal cracks in the solder joints.

Internal Quality Inspection: Advanced Technology for Precision and Durability

Plate Quality Inspection:

To maintain the integrity of our PCBs, we conduct chemical analysis tests to ensure that the PCB materials meet industry standards. We also evaluate the internal structure of the PCB, inspecting for fiber alignment and potential issues like delamination or internal bubbles.

Conductivity Testing:

Using high-precision four-probe testers, we assess the conductivity of the PCB. This ensures that the conductive paths are clear, with no open circuits or shorts, guaranteeing the board performs reliably under normal operating conditions.

Insulation Performance Testing:

With the help of high-voltage testing equipment, we test the PCB's insulation layer to ensure it can withstand specified voltages without failure. Our rigorous tests check for uniform coating of insulation material, ensuring there are no gaps or inconsistencies.

Thermal Performance Testing:

We conduct thermal shock and thermal cycling tests to assess the PCB's stability under extreme temperature conditions. By subjecting the PCB to high and low temperatures, we simulate the stresses it may experience in real-world applications. We ensure that the PCB does not deform, crack, or delaminate under such conditions.

Environmental Adaptability Testing:

Our testing processes also include salt spray tests, mold tests, and vibration simulations to evaluate the PCB's durability in harsh environments. These tests help determine the PCB’s resilience to corrosion, humidity, and mechanical stress, ensuring it can withstand the most demanding conditions.

Key PCB Manufacturing Equipment: Showcasing Our Expertise

At Fast Turn PCB, we utilize industry-leading equipment to maintain the highest standards of PCB manufacturing. Here are some of the advanced tools we use:

LDI (Laser Direct Imaging):

This cutting-edge technology allows for precise imaging and high-resolution patterning on the PCB, reducing the risk of errors and improving overall production efficiency.

Lamination Equipment:

Our lamination machines provide a uniform bond between layers of the PCB, ensuring structural integrity and enhancing the electrical performance of the finished board.

Gold Finger (ENIG) Processing:

The Electroless Nickel Immersion Gold (ENIG) process is used for high-quality surface finishing on connectors and critical interfaces. This ensures excellent conductivity and durability, especially for high-frequency applications.

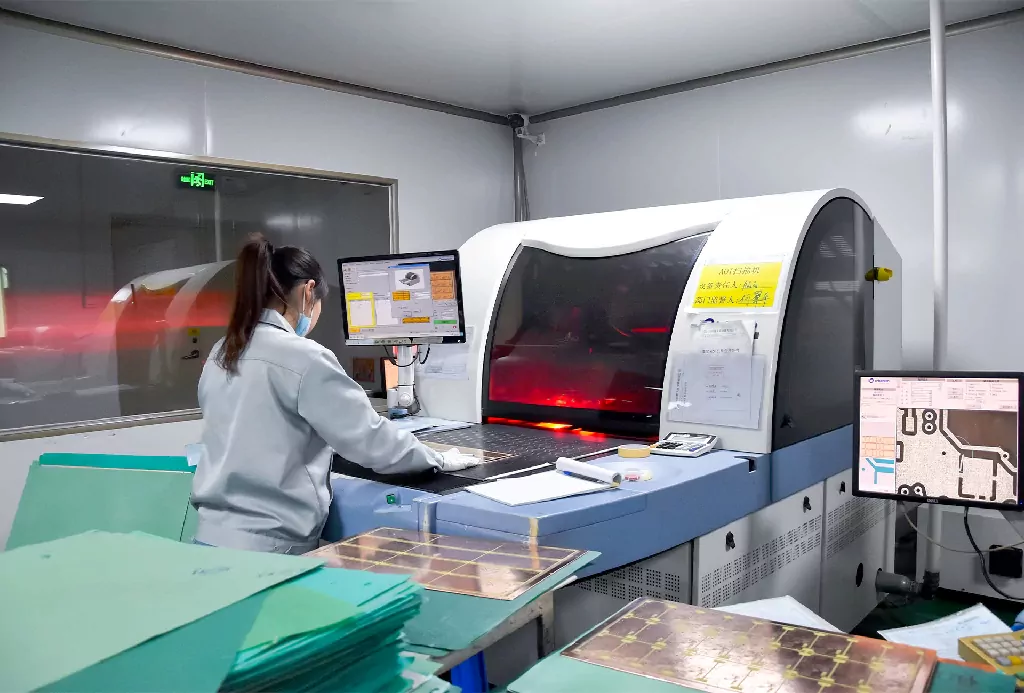

AOI Scanners:

Our Automated Optical Inspection (AOI) systems use high-resolution cameras and advanced algorithms to identify surface defects such as soldering issues, missing components, and trace integrity problems. This allows us to catch potential issues before they escalate.

Flying Probe Testers:

The Flying Probe Testers conduct electrical testing of the PCB without the need for complex fixtures. This provides flexibility and high accuracy in detecting electrical shorts, opens, and other faults in the PCB’s design.

Impedance Testers:

Our impedance testing equipment ensures that the PCB maintains proper signal integrity, which is critical for high-speed digital applications. These tests check for any impedance mismatches in the traces that could affect signal transmission.

Our Commitment to Excellence

We are dedicated to providing the highest quality PCBs by using the best equipment and industry-leading inspection techniques. Our commitment to precision and reliability ensures that our customers receive products that meet or exceed their expectations, every time.

Whether you're in the automotive, telecommunications, consumer electronics, or industrial sectors, our PCB manufacturing processes are designed to meet the stringent demands of modern electronic systems. Partner with us today to experience the difference that superior technology and expert craftsmanship can make in your projects.