When choosing PCB hard board and FPC soft board, multiple factors need to be considered, including application requirements, performance characteristics, cost budget, and production process. The following is a detailed comparison and selection suggestion for the two:

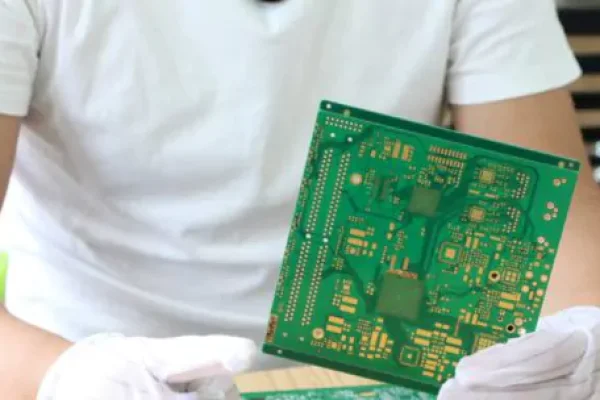

Characteristics of PCB Hard Board

High strength:

PCB hard boards have high mechanical strength and stability, and can withstand significant mechanical stress and high temperature environments.

Moisture and corrosion resistance:

It has good moisture and corrosion resistance and can be used for a long time in humid environments.

Good processing performance:

Hardboard processing is simple and easy to weld, so it is widely used in industrial production.

Application scenarios:

Usually used in equipment that requires significant mechanical stress or high temperature environments, such as computer motherboards, servers, industrial controllers, etc.

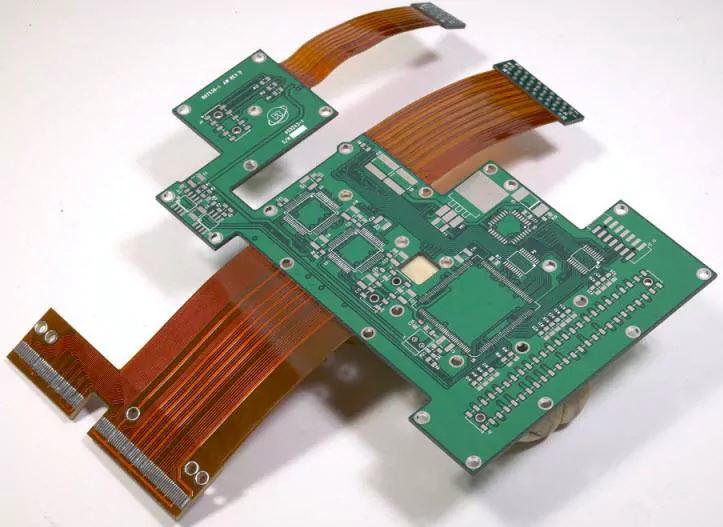

Characteristics of FPC Soft Board

Good flexibility:

FPC flexible board has high flexibility and bendability, which can adapt to various complex environments and space limitations.

Lightweight:

Lightweight and thin, which is conducive to the miniaturization and lightweighting of electronic products.

Good heat dissipation:

It has good heat dissipation and weldability, and is easy to install and connect.

Application scenarios:

Widely used in highly integrated, lightweight, foldable or bendable electronic devices, commonly used in connectors to achieve flexible connections between different modules.

Choose Suggestions

Choose according to application requirements:

If the device needs to withstand significant mechanical stress or high temperature environments, or has high requirements for moisture and corrosion resistance, it is recommended to choose PCB hard boards. If the device requires high integration, lightweight, foldable or bendable, or has high requirements for spatial layout, it is recommended to choose FPC flexible board.

Considering cost budget:

Generally speaking, the production cost of FPC soft boards is higher than that of PCB hard boards because they use more expensive flexible materials and more complex manufacturing processes. Therefore, when making a choice, it is necessary to weigh the cost budget and performance requirements.

Consider production process:

The manufacturing process of PCB hard boards is relatively mature and stable, including multiple steps such as graphic design, board cutting, drilling, electroplating, etching, etc.The manufacturing process of FPC flexible board is more complex, including the selection of thin film materials, the production of circuit graphics, lamination, electroplating, etching, and subsequent assembly and testing. Therefore, when choosing, it is necessary to consider the complexity and feasibility of the production process.

In summary, PCB hard boards and FPC soft boards each have their unique advantages and applicable scenarios. When making a choice, it is necessary to comprehensively consider factors such as specific application requirements, cost budget, and production process.