When it comes to PCB Fabrication Low Cost, “cheap” doesn’t have to mean “poor quality.”

The smartest engineers know how to balance materials, surface finish, testing, and delivery time to get affordable boards without cutting corners.

This guide explains how PCB costs are structured, what to prioritize or avoid, and how to choose the best suppliers in 2026 — with FastTurn PCB a top low-cost, high-quality manufacturer.

What Really Determines PCB Price

At first glance, all cheap PCB quotes look similar — until you check what’s included.

Total “landed” cost = base material + layer count + surface finish + testing + lead time + shipping/tariffs.

Here’s what drives the difference:

- Material (substrate and copper thickness): FR-4 is the standard, while high-Tg or Rogers materials can double the cost.

- Structure (layers and board thickness): Each additional layer increases the number of lamination and drilling steps.

- Process (surface finish, impedance, solder mask): Non-standard finishes or colors add up fast.

- Quality (electrical test and inspection): Flying-probe testing is cheap insurance for prototypes.

- Lead time (turnaround + logistics): 24-hour rush orders can cost 50–100% more than standard 7-day builds.

The lowest price per piece isn’t always the lowest total cost — especially once you include shipping and import fees.

Material Selection: When FR-4 Is “Good Enough.”

For 90% of digital and power designs under 200 MHz, standard FR-4 works perfectly.

It’s inexpensive, reliable, and widely available in 1-oz copper.

Only step up to specialized laminates when your project requires it:

| Standard FR-4 | ★ | Most prototypes and consumer devices |

| High-Tg FR-4 | ★★ | High-temp or automotive environments |

| Aluminum-base | ★★ | LED and power applications |

| Rogers / PTFE | ★★★ | RF / microwave circuits |

| Heavy copper (2–4 oz) | ★★ | Power or heat-spreading designs |

Stick with FR-4 unless your dielectric or thermal requirements demand otherwise.

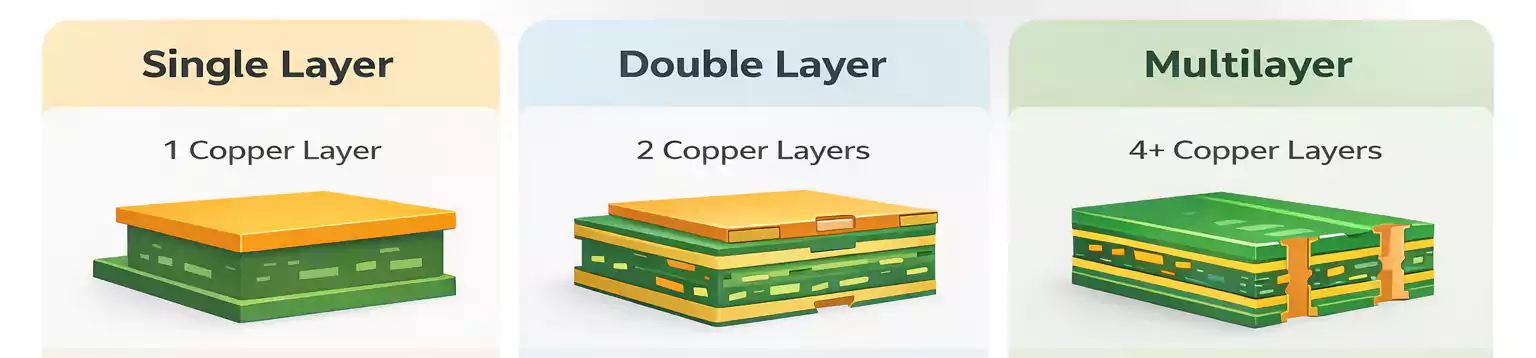

Layer Count and Board Thickness

More layers mean higher cost and complexity.

The sweet spot for most prototypes is 2- or 4-layer boards at 1.6 mm thickness with 1 oz copper — the global fabrication standard.

Choose thinner boards (0.8–1.2 mm) only when space or connector constraints require them.

Those may trigger special handling fees or concerns about rigidity.

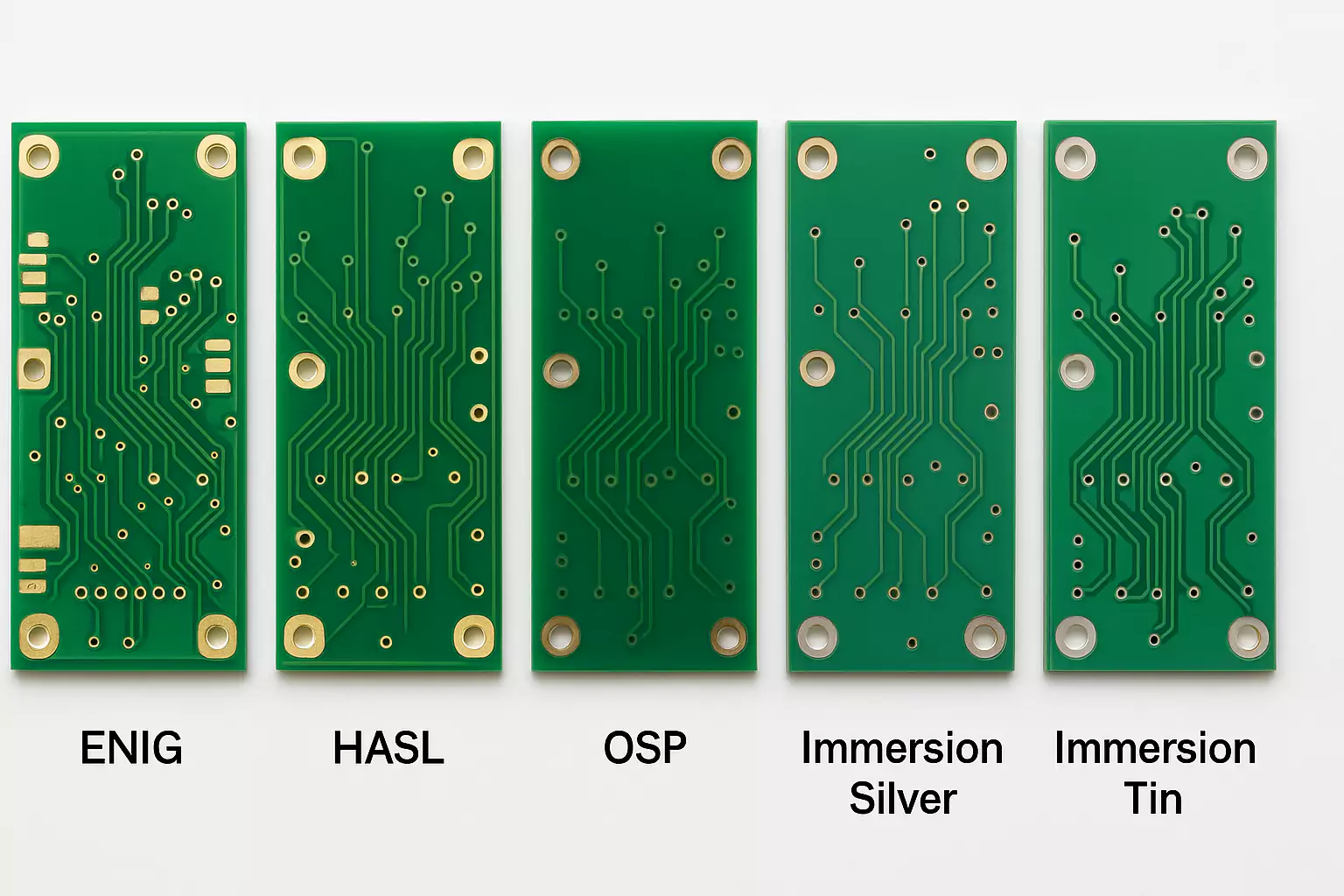

Surface Finish: Where Quality Meets Cost

Surface finish protects copper from oxidation and ensures solderability — but it’s also one of the biggest cost levers.

| HASL (lead) | ★ | Cheapest | Not RoHS | Prototypes, through-hole boards |

| HASL (lead-free) | ★★ | RoHS, easy to solder | Uneven for fine-pitch parts | General purpose |

| ENIG | ★★★ | Flat, reliable, long shelf life | Highest cost | BGA, fine-pitch, reflow critical |

| OSP / Imm. Silver / Imm. Tin | ★★ | Clean surface | Short shelf life | Quick-turn production |

Rule of thumb: choose HASL unless you have fine-pitch BGAs or gold fingers that require ENIG.

Drilling and Design Tolerances — The Hidden Cost Triggers

Tiny holes and tight tolerances are silent price multipliers.

Reducing the minimum via size from 0.3 mm to 0.2 mm may double your drill time and cost.

Blind/buried vias, back-drilling, or slot milling instantly push your order into the “advanced process” pricing tier.

Safe baseline for low cost:

- Min. trace/space ≥ 6 mil

- Min. hole ≥ 0.3 mm

- Avoid blind/buried vias unless absolutely needed.

Solder Mask and Silkscreen: Looks vs. Budget

“Green saves green.”

Green solder mask is the cheapest, fastest, and most reliable option.

Black or white inks look premium, but they increase costs and the risk of yield issues.

Similarly, keep silkscreen text functional — fewer layers, less cleanup, lower cost.

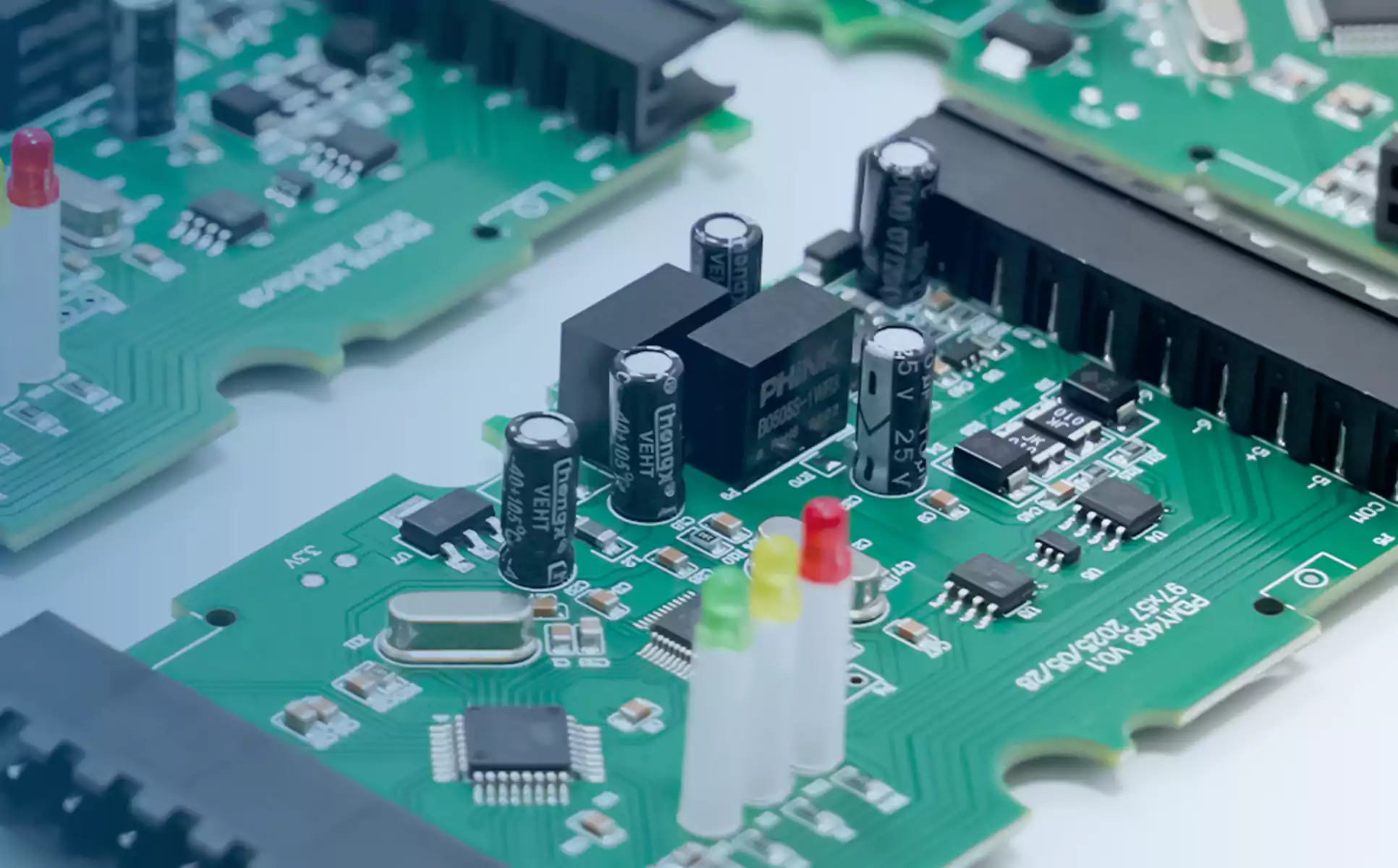

Testing and Quality: Spend a Little, Save a Lot

Electrical testing is non-negotiable, even for prototypes.

- Flying-probe test: The standard for low-volume builds; catches shorts and opens early.

- Fixture (bed-of-nails): Worth it only for high-volume runs.

- AOI / X-ray / Impedance checks: Default in quality-controlled fabs; optional for hobby builds.

Skipping testing to save a few dollars often leads to re-spins and weeks of delay.

Lead Time and Logistics: Time = Money

Shorter turnaround = higher price, exponentially.

| 7–10 days | Base price | Standard builds |

| 3–5 days | +20–30% | Urgent prototypes |

| 24–48 h | +50–100% | Critical demos or repair jobs |

Proven Ways to Save Money Without Sacrificing Quality

- Stick to standard specs: FR-4, 1.6 mm, 1 oz, green mask, HASL, flying-probe, standard lead time.

- Upgrade only if your package pitch or BGA density requires it.

- Keep via sizes ≥ 0.3 mm and avoid blind/buried vias.

- Panelize small designs to reduce setup cost.

- Skip fancy solder mask colors and over-detailed silkscreens.

- Always run DFM/DFT checks before submitting.

- Always run the electrical test — it’s cheap insurance.

- Calculate landed cost, freight, and tariff included, not just the quoted price.

- For fast or confidential jobs, consider local assembly.

- Remember: PCB ≠ PCBA — assembly pricing varies widely.

Choosing Your Supply Path: Overseas vs. Local Quick-Turn

- Overseas volume fabs (China, SE Asia): unbeatable on standard specs and pricing. Best for non-urgent prototypes and larger batches.

- Local quick-turn fabs (U.S. / EU): higher per-board cost but lower risk, faster logistics, and better engineering communication — ideal for rush or sensitive projects.

Top 10 PCB Fabrication Low Cost Manufacturers

Based on cross-analysis of public reviews, capabilities, and rankings from major PCB industry sources.

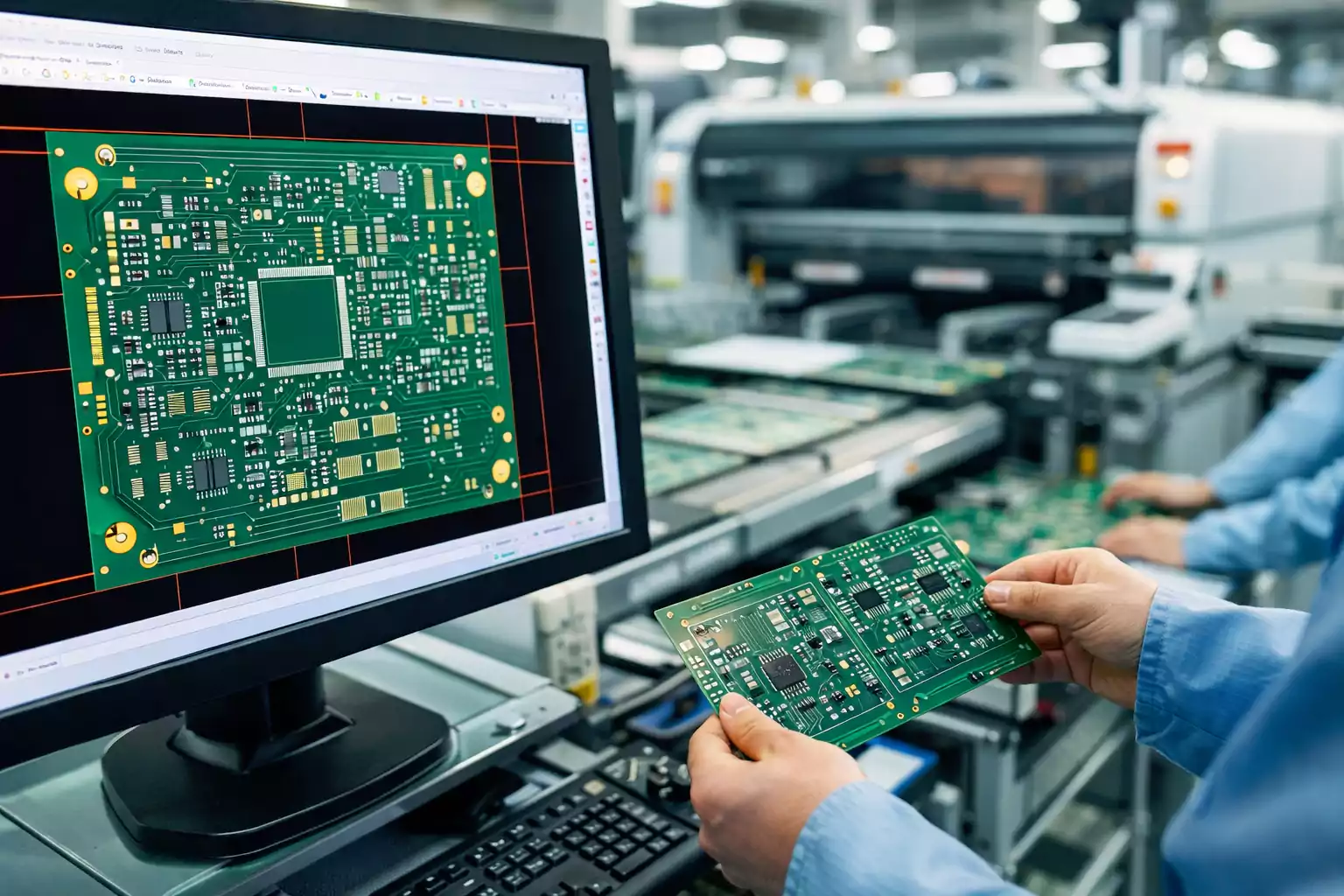

1. FastTurn PCB

Positioning: From rapid prototyping to small-batch full-turnkey production.

Strengths:

- 24-hour turnaround options with real-time response and instant quotes

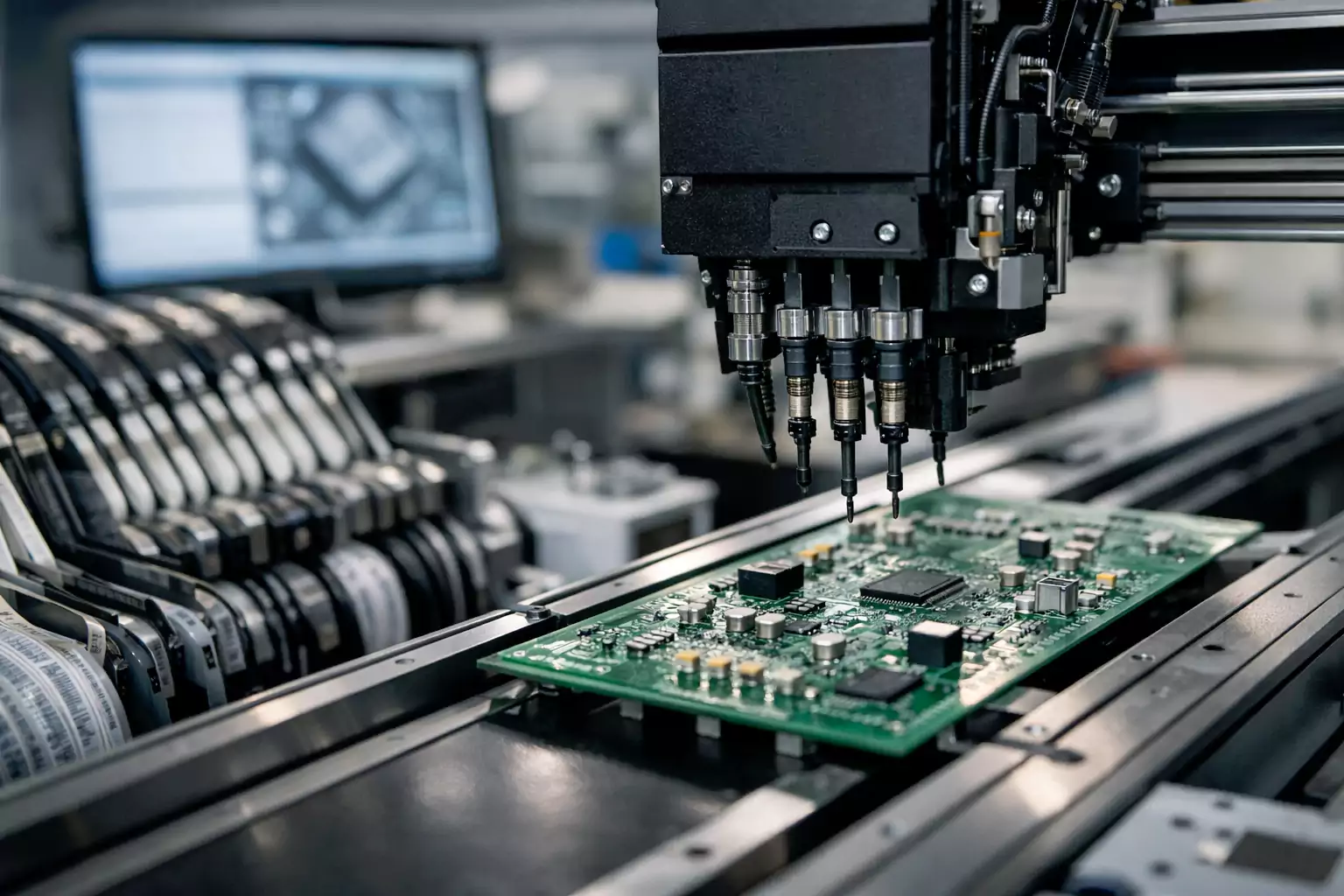

- End-to-end service: PCB fabrication + component sourcing + SMT/BGA assembly + testing

- Robust quality system (IPC/UL/ISO) and in-house factory capabilities

- U.S.-friendly communication (email, phone, WhatsApp)

Best for: Startups, design teams, and OEMs needing fast, affordable, and reliable prototype-to-production transition.

2. Hemeixin PCB & Assembly

Focuses on low-volume, high-mix builds, including flex and HDI.

Excellent for multi-technology prototypes or short-run RF designs.

3. PCBWay

Highly standardized, transparent pricing, and a strong global reputation.

Best for budget prototypes and standard 2–6-layer builds.

4. JLCPCB

Known for ultra-low entry prices (e.g., $2 for 5 pcs).

Perfect for simple, price-sensitive prototypes.

5. Advanced Circuits (4PCB)

U.S.-based fab with reliable quality and local logistics.

Good choice for domestic quick-turn and ITAR-sensitive work.

6. OSH Park

Maker-friendly and community-trusted.

Purple boards, fixed pricing — great for DIY and hobbyist runs.

7. Seeed Studio

Strong ecosystem and prototyping support; good for development boards and integrated builds.

8. Eurocircuits

European fab with detailed DFM feedback tools.

Ideal for engineering teams prioritizing manufacturability.

9. Bittele Electronics

Turnkey manufacturing with full component procurement.

Saves teams time without in-house purchasing.

10. Wintech

Comprehensive EMS provider for low- to mid-volume builds.

Best suited for complex assemblies and industrial customers.

Quick FAQ

Q: HASL or ENIG — which is better?

A: HASL for standard parts; ENIG for fine-pitch or BGA packages.

Q: Is green solder mask really cheaper?

A: Yes — it’s the industry standard with the best yield and lead time.

Q: Do I need flying-probe testing on prototypes?

A: Absolutely. It prevents expensive re-spins later.

Q: Why is my “$2/5 pcs” board more expensive at checkout?

A: Shipping, taxes, non-standard colors, or urgent lead time add up.

Q: Why is PCBA pricing so different?

A: Assembly depends on part sourcing, soldering complexity, and labor costs — it’s not as standardized as PCB fab.

Why Choose FastTurn PCB

At FastTurn PCBs, you get more than just PCB Fabrication Low Cost:

You get speed, quality, and engineering support in one place.

- 1-piece prototypes to small-batch builds

- As fast as a 24-hour turnaround

- Full DFM/DFT review and design assistance

- Certified IPC/UL/ISO quality system

- Seamless transition from PCB fabrication to turnkey assembly

That’s how you make “low cost” truly mean “high value.”

Conclusion

PCB Fabrication Low Cost is not about chasing the lowest quote —

It’s about choosing the right specs and supplier to minimize total cost, risk, and rework.

Stick with standard parameters, invest in testing, and partner with proven manufacturers like FastTurn PCB for fast, affordable, and dependable results.