What Is PCB Coating (Conformal Coating)?

PCB coating—also called conformal coating—is a thin protective film applied to a printed circuit board to protect it against moisture, dust, salt spray, chemicals, and other environmental factors. The word conformal means the coating conforms to the contours of components and traces, creating an even, insulating barrier without altering the board's shape.

A proper coating improves long-term reliability by preventing corrosion, leakage currents, and short circuits caused by humidity or contamination, especially in harsh environments such as outdoor, automotive, or industrial settings.

Is PCB Coating Waterproof?

A common misunderstanding is that conformal coating makes a PCB completely waterproof. In reality, these coatings are moisture-resistant, not waterproof. They slow down the penetration of water vapour but remain slightly permeable.

If your design will be fully submerged or constantly exposed to liquids, you’ll need potting or encapsulation, which seals the board in a solid resin layer instead of a thin film.

When Do You Need PCB Coating?

You’ll typically apply coating when the board will operate in conditions that could cause corrosion or leakage. Examples include:

- Outdoor or marine electronics are exposed to humidity and salt air.

- Automotive ECUs and power modules under thermal and vibration stress

- Industrial equipment working near chemicals, fumes, or dust

- Medical and military electronics that must meet reliability standards

The Five Main Types of Conformal Coating

Each coating chemistry has distinct strengths and trade-offs. Choosing the right one depends on the environment, rework frequency, and cost targets.

| Acrylic (AR) | Fast drying, low cost, easy to remove and repair | Poor chemical resistance | 25–75 µm | Prototypes, consumer, general protection |

| Urethane (UR) | Strong chemical and abrasion resistance | Harder to rework | 25–75 µm | Automotive, industrial controls |

| Silicone (SR) | Wide temperature range, flexible, great moisture resistance | Long cure, low solvent resistance | 50–100 µm | Power supplies, LED drivers, outdoor gear |

| Epoxy (ER) | Tough, excellent chemical resistance | Very rigid, hard to remove | 50–150 µm | Harsh chemical or thermal environments |

| Parylene (XY) | Vacuum-deposited, ultra-thin, uniform, pinhole-free | Expensive equipment, long process | 10–50 µm | Medical, aerospace, precision sensors |

Acrylic coatings are popular for general electronics due to their balance of protection and repairability. Silicone is best for high humidity and temperature swings. Parylene provides top coverage where uniformity and thinness matter most.

Application Methods

Spray Coating (Aerosol or Spray Gun)

Spraying is quick and ideal for small batches or field repair. Aerosol cans are convenient for lab use, while spray guns give better control for larger runs. Key points: mask connectors and switches, spray 8–10 inches from the surface, overlap passes, and allow flash-off between layers.

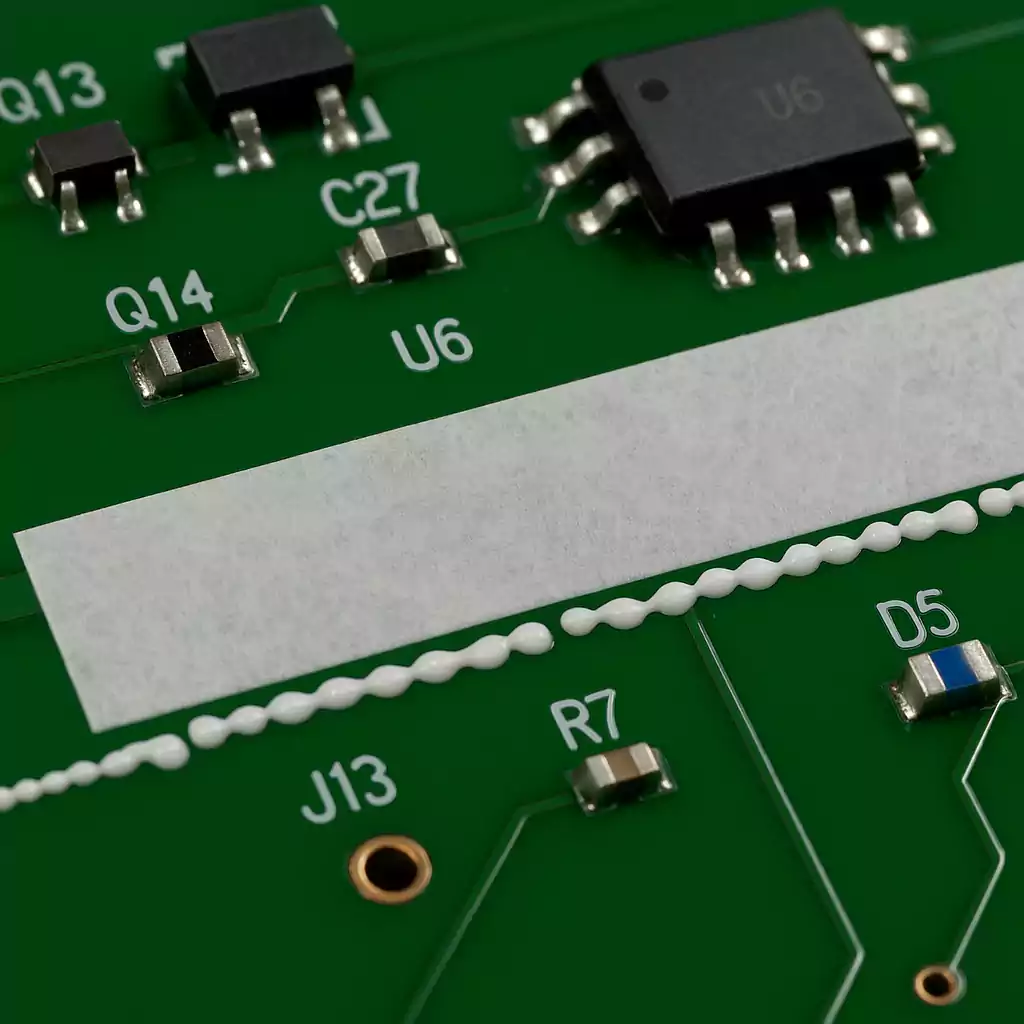

Brush Coating

The simplest method. Apply a thin, even layer with a soft brush. Best for prototypes or spot repair. Surface cleanliness is critical—brushing can trap dust or bubbles if done too thickly.

Dip Coating

The board is dipped into a tank of coating and withdrawn slowly. It offers excellent consistency and coverage but requires good fixturing and venting to prevent air pockets. Masking is essential to protect connectors and test pads.

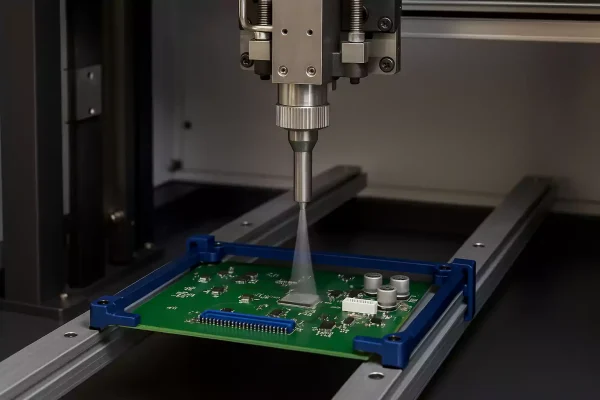

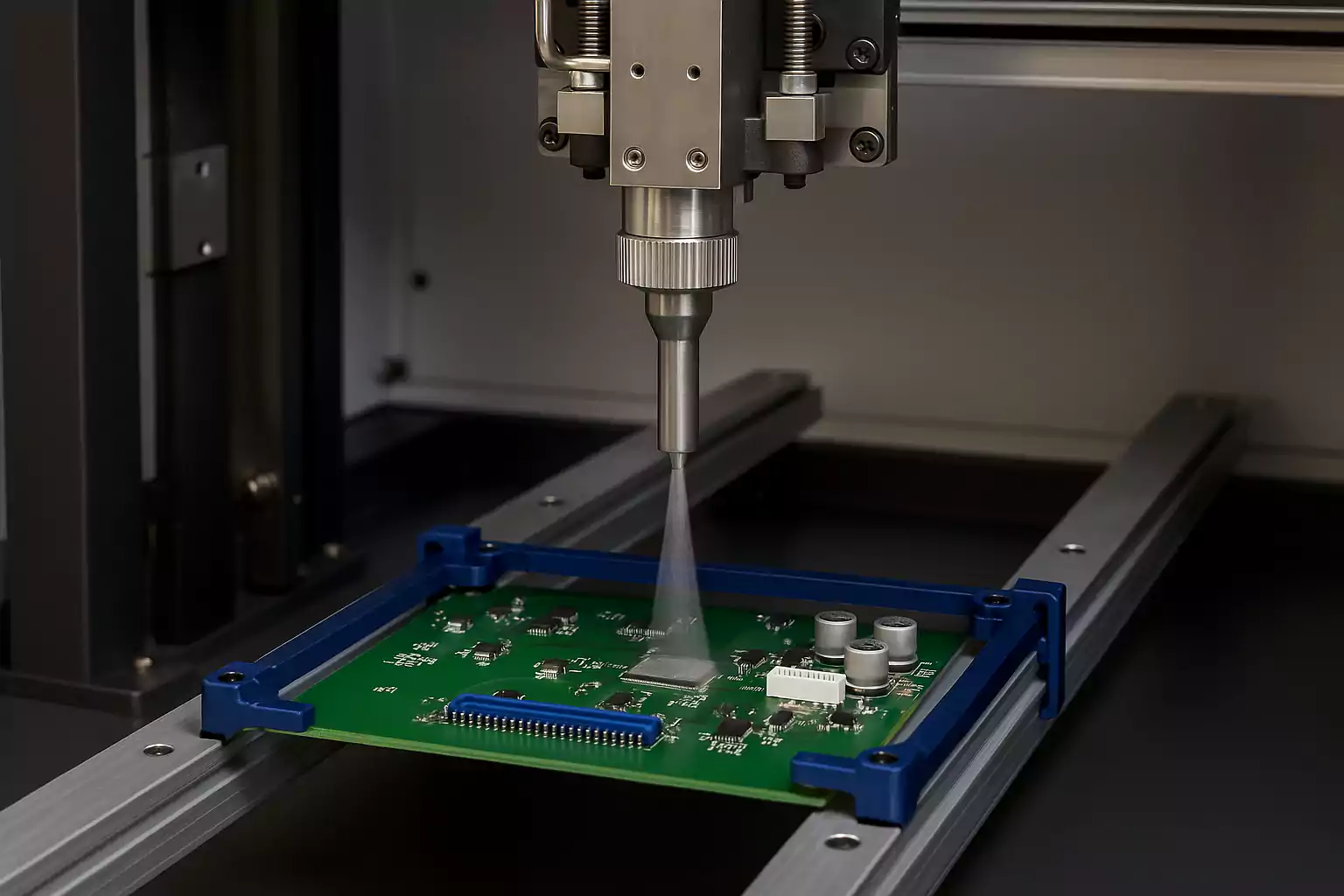

Selective Coating

Automated selective coating systems are common in mass production. A programmed nozzle applies material only where needed, automatically avoiding sensitive areas.

Parylene Deposition

Unlike liquid coatings, parylene is vapour-deposited under vacuum. The gas penetrates every corner, forming an ultra-uniform, pinhole-free layer. It delivers the best coverage but at a much higher cost.

Coating Thickness, Curing, and Inspection

Conformal coating thickness typically ranges from 25 µm to 127 µm. Thicker coatings offer more protection but can trap solvents or reduce heat transfer.

Curing Methods

- Solvent Evaporation: Air dry, common for acrylics.

- Heat Cure: Speeds up polymerisation for urethane and epoxy.

- Moisture Cure: Used by some silicones; requires ambient humidity.

- UV Cure: Instant hardening under ultraviolet light; popular in fast production lines.

Signs of poor cure include tacky surfaces, whitening, or fingerprints after drying.

Inspection

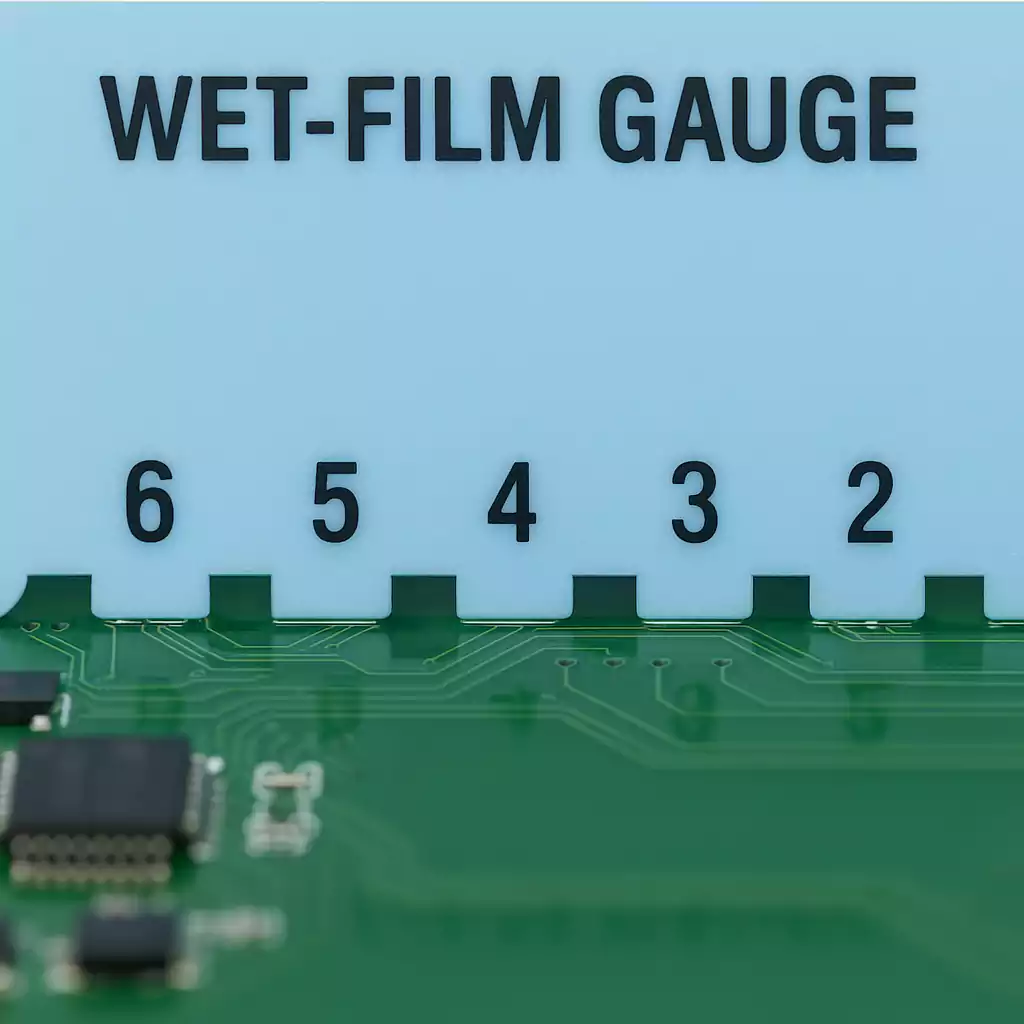

Most coatings include a UV tracer for coverage checks under blacklight. Thickness for critical builds is verified using wet-film gauges or weight comparison, ensuring compliance.

PCB Design and Manufacturing Tips

Good coating results start at the design stage:

- Keep-out zones: Mark areas that must remain uncoated, such as connectors, test points, adjustable components, and buttons.

- Vent holes: Allow trapped air to escape during dip or spray.

- Creepage and clearance: Coating improves dielectric strength, but you still must maintain safety spacing for high-voltage circuits.

- Thick coatings insulate. Avoid covering heat-generating components, or use thermal vias and pads to effectively manage heat dissipation.

- Masking: Use silicone or high-temperature tape and reusable boots for connectors. Proper masking saves hours of cleanup.

How to Choose the Right Coating: A Three-Step Approach

Step 1 – Evaluate the Environment

Identify main stress factors—humidity, temperature, salt, chemicals, or vibration. Rate each as low/medium/high.

Step 2 – Select the Material

Use the rating to shortlist candidates:

- High humidity and temperature → Silicone

- Chemical splash or abrasion → Urethane/Epoxy

- Lightweight prototypes or lab testing → Acrylic

- Complex shapes or mission-critical → Parylene

Step 3 – Pick the Application Process and Thickness

- For small batches, use a spray or a brush.

- For high volumes, use selective coating or dip.

- For premium protection, choose Parylene deposition.

Adjust film thickness according to material: thin for parylene, moderate for acrylics, and thicker for silicones.

Cleaning, Flux, and Rework Considerations

Cleanliness is everything in conformal coating. Ionic residue trapped under the film can cause corrosion or dendritic growth. Always clean and bake boards before coating to remove flux and moisture.

When rework is needed:

- Acrylics can be removed with common solvents like acetone or specialised removers.

- Silicones and urethanes require stronger solvents or gentle mechanical abrasion.

- Epoxies are almost permanent and may need localised heating and scraping.

After repair, clean the area again and apply a touch-up coating for full protection.

Common PCB Coating Defects and How to Fix Them

- Pinholes or Bubbles – Caused by trapped air or poor cleaning.

Fix: Improve surface preparation, reduce coating thickness, and allow longer flash time. - Fish-Eyes or Receding Areas – Usually from silicone oil or grease contamination.

Fix: Use powder-free gloves, avoid silicone lubricants, and re-clean parts. - Orange-Peel or Rough Surface – Spraying too far or using high viscosity material.

Fix: Adjust the thinner ratio, reduce the spray distance, or increase the pressure slightly. - Cracking or peeling – From excessive thickness or poor adhesion.

Fix: Lower coating build, ensure parts are dry, and match the thermal expansion of materials. - Edge Pooling or Drips – From heavy spray passes or gravity sag.

Fix: Apply multiple light coats and adjust the board angle during drying.

Early detection under UV light can save rework time and prevent reliability failures.

FAQ

1. What are PCBs coated with?

They’re typically coated with polymers such as acrylic, silicone, urethane, epoxy, or parylene, which create a thin insulating layer.

2. What is the best coating for PCB?

There’s no single “best.” Acrylic is easy to apply and repair; silicone handles moisture and temperature; urethane and epoxy resist chemicals; parylene gives the ultimate protection for critical parts.

3. What is the purpose of PCB coating?

To protect against moisture, dust, and contaminants, improve dielectric strength, and extend product life.

4. What are the problems with PCB coating?

Common issues include bubbles, pinholes, peeling, and difficulty with rework. Most result from poor cleaning, wrong viscosity, or incorrect curing.

5. Is conformal coating waterproof?

It’s water-resistant but not waterproof. For full immersion, use potting or encapsulation instead.

6. How thick should conformal coating be?

Typically between 25 µm and 127 µm (1–5 mil), depending on the material and environment.

Final Thoughts

An effective PCB coating strategy starts by understanding the environment and reliability needs. Select a compatible coating material and application process, with cleanliness as the foundation.

When done correctly, conformal coating is one of the simplest and most cost-effective ways to make electronics tougher, longer-lasting, and ready for the real world.